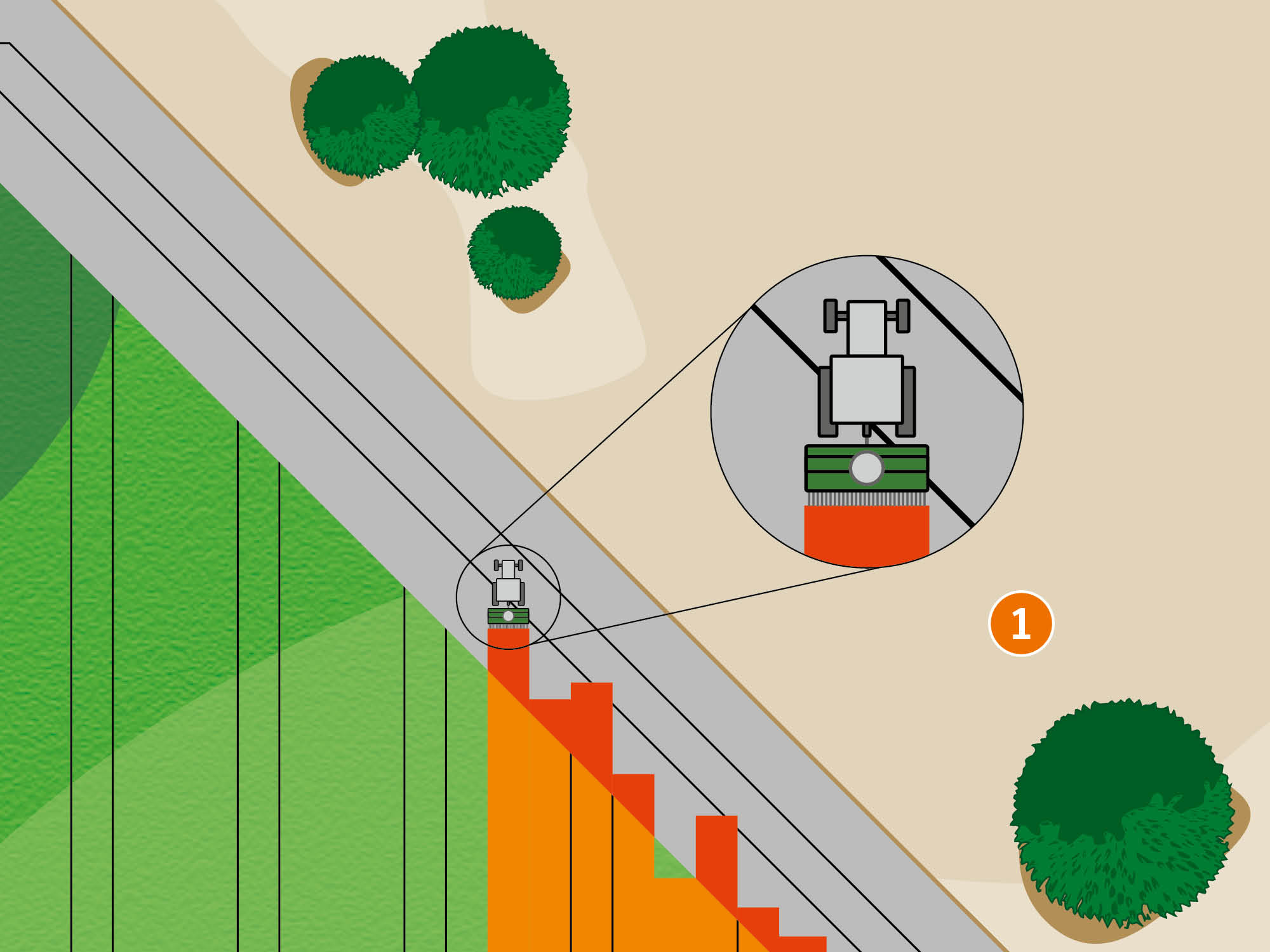

If the operating terminal features Section Control, such as, for example, GPS-Switch part-width section control from AMAZONE, the switching of the part-width sections can be carried out completely automatically and in relation to the GPS position. Once a field has been created, and then in automatic mode, the driver can concentrate fully on the operation of the towing vehicle, since the part-width sections are switched automatically in wedge shaped fields and on headlands.

Advantages of the automatic part-width section control:

- Stress relief on the driver

- Increase in precision especially at night or at higher speeds

- Fewer overlaps and gaps

- Saving on input costs

- Less crop damage and less environmental pollution

“With Section Control, the ISOBUS computer relieves the driver from a lot of work.”

(“dlz agrar magazine” – “Test report ZA-TS fertiliser spreader”· 02/2017)

Up to 85 %* less overlap in comparison to conventional Section Control part-width section switching, e. g. on the headland

* Savings are dependent on field structure, boom width and the number of part-width sections