Sep 12, 2023

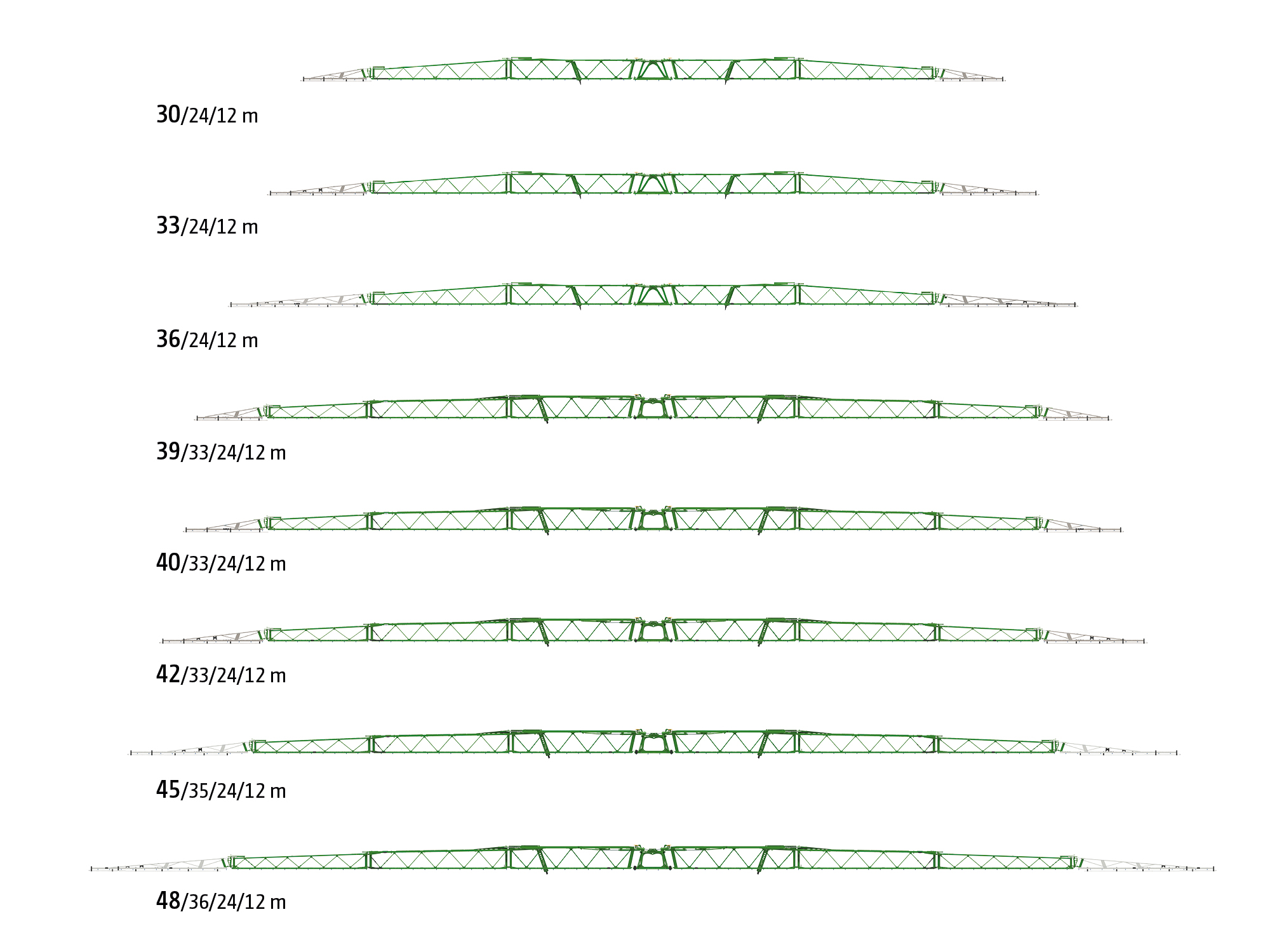

New Super-L3 boom now in up to 48 m working width

Maximum precision as a result of new swing compensation system through ContourControl and SwingStop Plus

Maximum working width with the best boom ride

AMAZONE developed the Super-L3 booms for the most extreme conditions and an absolutely smooth boom ride. The product range previously covered booms in working widths of 36 - 42 m. However, now the 30 m, 33 m, 45 m and 48 m wide versions have been added. The 45 m and 48 m versions also feature a swing compensation system which has been developed from scratch. This will be implemented in all Super L3 booms as standard from a working width of 39 m.

Large working widths with maximum stability and a low weight

The special AMAZONE profile design of the boom provides maximum stability with a low weight. The inner boom sections of the Super-L3 boom are made of steel. The outer boom sections consist of aluminium to keep the total weight down to a minimum. The advantage of the light-weight outer boom sections is that only a little amount of extra weight has to be guided smoothly over the crop on the outside. Smooth boom guidance at the boom ends is extremely important, especially in the case of large working widths. The profiles of the penultimate boom section of the 48 m wide Super-L3 boom are made of carbon fibre for maximum stability with a low weight.

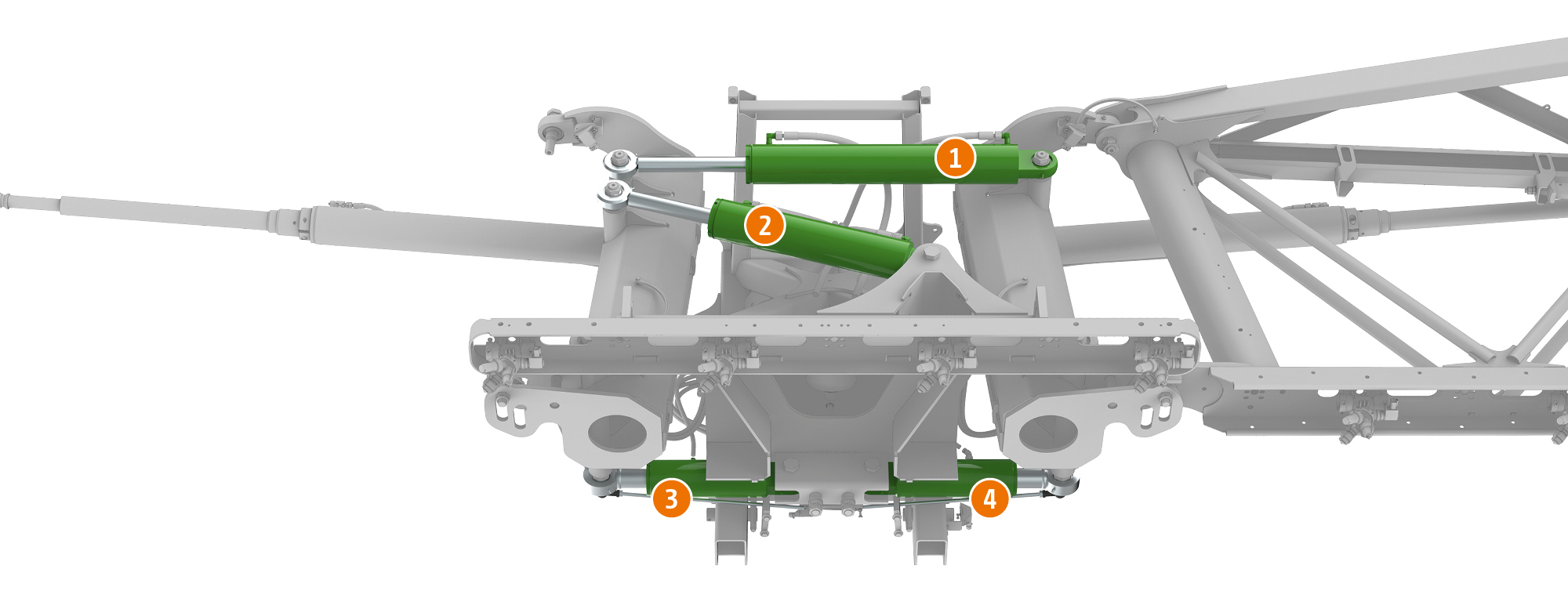

New swing compensation system

The swing compensation system is located in the middle of the boom and joins the parallelogram to the left-hand and right-hand booms. The swing compensation system has a very robust design, in order to meet the increased demands for high work rates at increased working speeds.

The new swing compensation system is equipped with the ContourControl active boom guidance system and the SwingStop plus active vibration damping as standard.

ContourControl – reduces those vertical boom movements

AMAZONE offers fully automatic boom guidance with the ContourControl active boom guidance system. This meets the increasing demand for higher precision during application owing to the minimal deviations in the distance from the target surface, even at high forward speeds and large working widths. For Super-L3 booms from 39 m, the ContourControl active boom guidance, in conjunction with the new swing compensation system, always includes Flex-fold 2. The basis of the boom guidance system is a highly responsive hydraulic system with 6 sensors which enable both automatic positive and negative angling.

The benefits of ContourControl:

- Optimum lateral distribution

- Precise, super-fast automatic height guidance

- Target surface distance below 50 cm – less drift

- Very quick folding in and out

- Higher accuracy at faster working speeds

- Elegant boom control for those wider working widths

SwingStop plus – the new active swing compensation system for reducing symmetrical and asymmetrical horizontal boom oscillations

The new swing compensation system for Super-L3 booms from 39 m includes SwingStop plus active vibration damping in order to tailor the horizontal boom ride to the increasing demands, such as larger working widths and higher forward speeds. External influences, such as ground undulations, driving round bends, acceleration and increasing working speeds - especially in the case of large working widths -place enormous loads on the boom in the horizontal plane. This may result in the boom ends swinging back and forth, thereby negatively affecting the lateral distribution at the outer ends of the booms.

As horizontal movement occurs more at the boom ends, this effect is increased enormously by wider boom widths. To reduce this horizontal tip swing effect, SwingStop plus measures the resulting acceleration at the boom ends via acceleration sensors. The two hydraulic rams in the swing compensation system actively compensate for these swing movements and thereby provide a very smooth horizontal boom ride. Each individual boom is controlled separately by SwingStop plus.

SwingStop plus can compensate for symmetrical oscillations which occur through acceleration and braking extremely effectively. The new design of the swing compensation system now permits the individual control of both booms. In SwingStop plus, each boom section is equipped with a hydraulic cylinder which actively counteracts any oscillations which occur in that boom half. This means that even asymmetrical boom oscillations which occur after negotiating bends are effectively reduced.

The benefits of SwingStop plus:

- Optimum longitudinal distribution

- Reduction in the horizontal boom movement for an extremely steady boom ride

- A system which operates very quickly and precisely, even at high working speeds

- Highest performance and outstanding precision

- Active reduction of symmetrical and asymmetrical oscillations

The interaction of ContourControl and SwingStop plus provides a very smooth boom ride at maximum working widths. This guarantees top-class application results with maximum area coverage.

AmaSwitch or AmaSelect individual nozzle control

The Super-L3 booms, from 39 m, are equipped with the manually-selected AmaSwitch individual nozzle control or the AmaSelect electric single nozzle control (incl. LED individual nozzle lighting) and DUS pro high-pressure recirculation system as standard. 25 cm nozzle spacing is available for both nozzle control systems as an option.

- Super-stable yet light-weight booms in a compact profile design

- High area coverage with maximum precision thanks to ContourControl and SwingStop plus

- AmaSwitch or AmaSelect precise individual nozzle control from choice

- Optimum application results

Super-L3 boom now in up to 48 m working width