Controlled Row Farming

Vision

Row-based cultivation with a particular focus on biodiversity

AMAZONE started a new long-term field trial programme in 2020.

Entitled "Controlled Row Farming" (CRF), a completely new arable farming system will be introduced, in which each plant cultivation measure takes place in relation to a fixed row.

The vision of the CRF agro-ecological farming system consists in the needs-based use of resources to generate reasonable yields and profits together with the maximum contribution to biodiversity.

The aim is to actively promote biodiversity and achieve a high level of efficiency in arable farming at the same time. The goals should not only be met but ideally also support each other.

Concept

All crop plants are grown with a row width of 50 centimetres in the CRF concept, whereby cereals are sown in double rows. Depending on the crop rotation, the row can be offset by 25 centimetres, e.g. in order to make use of the agronomical effect of the preceding undersown crop. Sowing is generally carried out in combination with row-oriented fertilisation. Plant protection is mainly provided row-specifically by means of band application on the row and with Dropleg systems at later growth stages. Each pass is always carried out with high-precision track guidance via RTK-GPS and camera control.

Hoeing technology is used for mechanical weed control in combination with row-specific plant protection, targeted fertiliser application and the sowing of companion plants between the rows. These companion plants – without direct contact with fertilisation and plant protection – make a positive contribution to the phytosanitary support of the main crop, soil fertility and biodiversity. Depending on the crop and weather conditions, these companion plants are actively managed, in order to ensure the crop is harvested.

Two different intensities will be compared in the CRF trials: one variant will put the emphasis on the maximum yield with limited competition from companion plants. The second variant will focus on biodiversity with reduced intensity of fertiliser and plant protection measures. The two CRF variants will be compared with two intensity levels of usual soil management.

Location

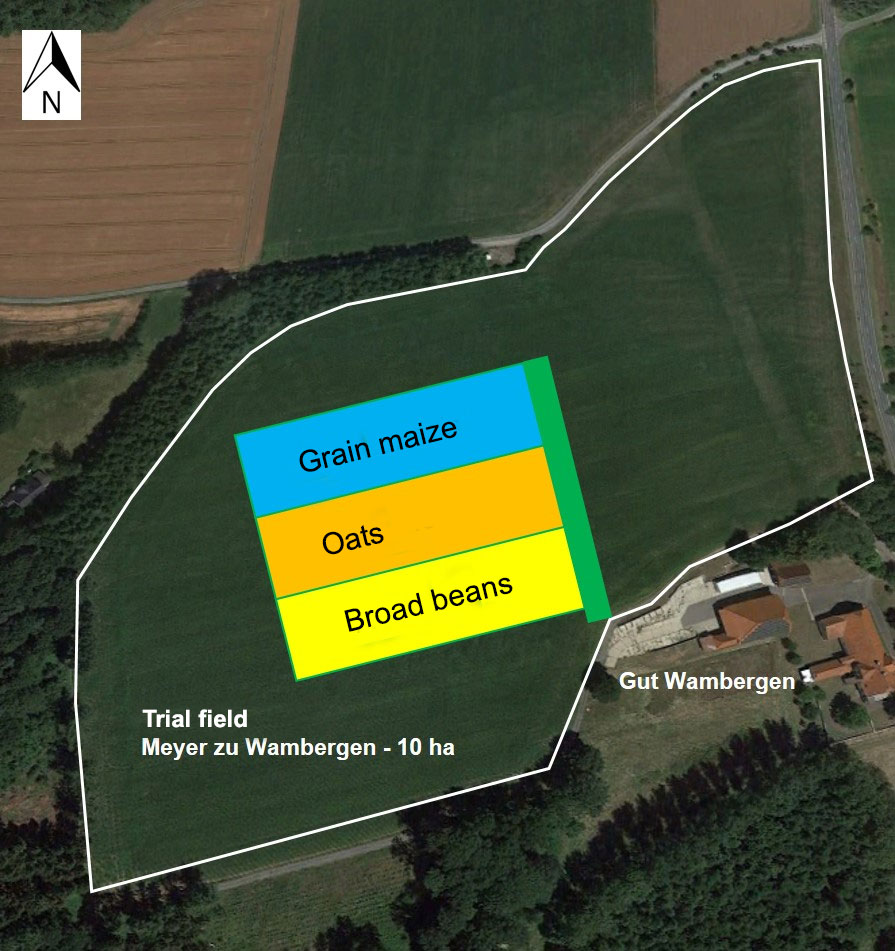

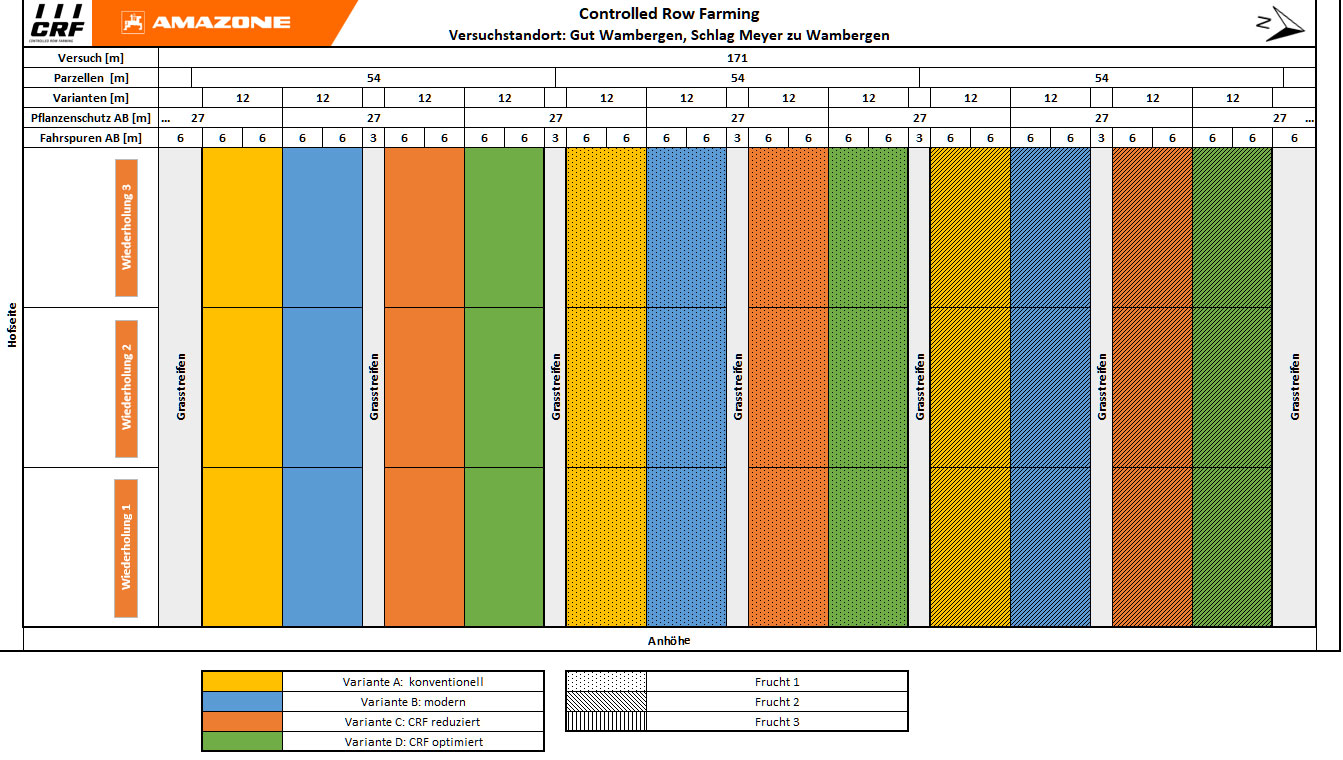

The 10 ha trial area at the AMAZONE trials centre in Wambergen is located in the immediate vicinity of the main AMAZONE plant in Hasbergen-Gaste.

The six-year crop rotation with cereals and maize is typical for the region. It is designed in accordance with the principles of sustainability with the cultivation of rape and pulses as well as intensive catch crop cultivation. The simultaneous cultivation of four crops in four variants on one area provides a good basis for the intensive exchange of information with the end users.

Partnership

As a plant breeding company steeped in tradition, Deutsche Saatveredelung AG (DSV) with its head office in Lippstadt is very closely connected with practical agriculture. New varieties for the international markets are continuously developed via a diverse array of breeding programmes in the major growing regions. The focus is on crop rotation here. DSV carries out pioneering work in the area of catch crops and additionally sown and undersown crops and actively takes part in designing the basic approach of evergreen cultivation systems. New varieties for the problems of tomorrow are developed via the in-house breeding programme in the biodiversity segment. The CRF cultivation system opens up very promising new opportunities and prospects which are being driven forward and developed in the common interest.

News

As part of our CRF trial in 2024/25, we compared two different variety types of winter barley: the pure line variety DSV Julia and the hybrid variety SY Loona. In addition, we tested different dates for sowing companion crops. The previous crop was winter...

White clover is an interesting plant for the undersown crop in the CRF method. This was demonstrated by our cultivation trial in 2023/2024. We also tested whether a robust and fast-growing catch crop can be developed from the undersown white clover. The...

Sowing of the companion crop in autumn – what benefits does this have for wheat? We grew wheat using the CRF method in the cultivation year 2023/2024. Three different companion plants/undersown crops were tested in the trial. The wheat was managed using the...

In addition to wheat, we grew rape as a second crop in 2023/2024 using the CRF method. However, the trial did not yield any conclusive results as a result of a heavy pest infestation, which is why we only give a brief summary here.

The second arable farming dialogue took place during this year's AMATECHNICA at AMAZONEN-Werke. The Controlled Row Farming (CRF) farming concept was the main topic of the event. Precision Farming trials and a comparison of direct vs. mulch sowing at Gut...

In addition to the demo trial at Gut Wambergen, a randomised field trial was also conducted in the region in cultivation year 2022, in order to provide a more detailed analysis of the CRF concept. A trial site with three repetitions on a sufficiently large...

After we treated the companion plants relatively defensively in the first years, we wanted to give priority to biodiversity for the winter wheat 2022/2023. The sowing of wild herbs in the CRF system without the application of herbicide in the intermediate...

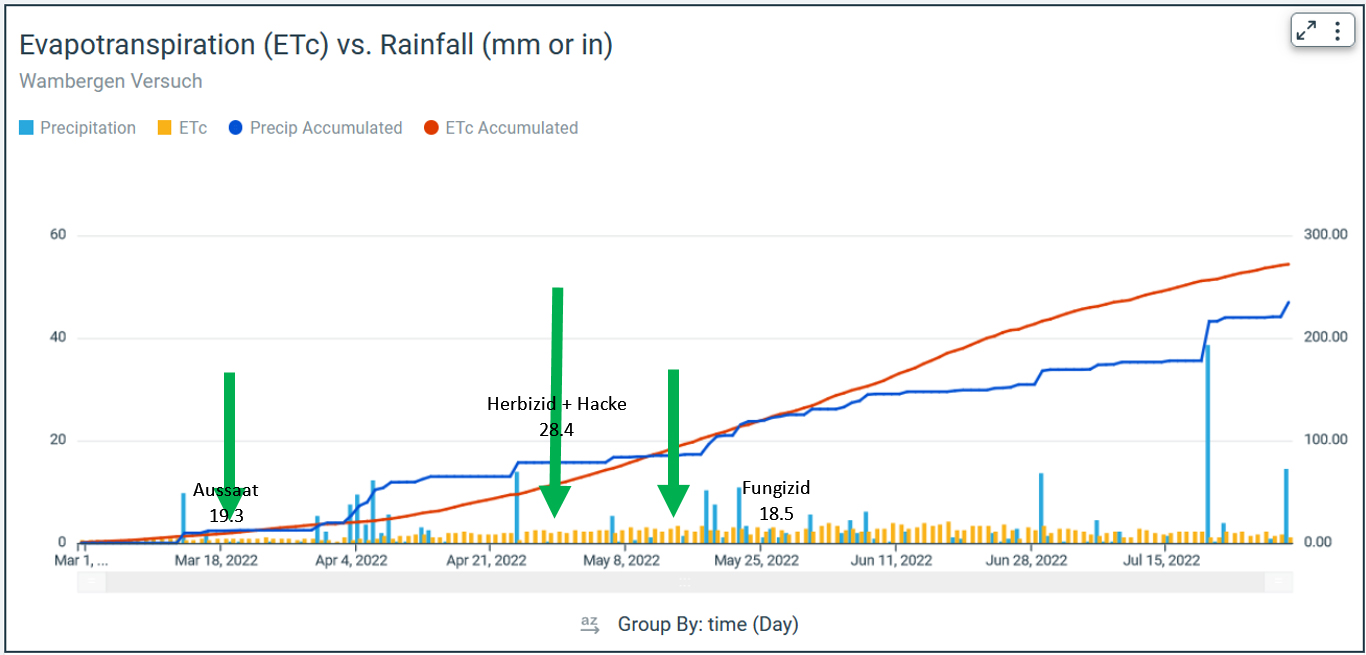

On 19th March 2022, oats of the Lion variety were sown in the Controlled Row Farming trial at Gut Wambergen. Interesting insights into the various control strategies against weeds were obtained after the harvest.

Three summer crops will be grown in the cultivation year 2022: field beans, oats and grain maize. The plots were restructured, and a uniform basis was created with a plough furrow.

The “DLG-Agrifuture Concepts” innovation prize for pioneering achievements and visions for the future in agricultural technology was awarded for the first time during Agritechnica. The “CRF - Controlled Row Farming” farming concept from Amazone, Agravis...

The Controlled Row Farming method of cultivation is being tested on a trial area in the immediate vicinity of the AMAZONEN-WERKE factory in Hasbergen-Gaste. The trials are for demonstration purposes and, following initial tests in 2020/2021, are now being...

All winter barley trial variants produced the same yields in the 2021 harvest! There are also no differences between the double row with a 50 cm row width with undersowing and the other variants. Winter barley of the variety "KWS Wallace" was sown on...

Apart from the practical implementation of the Controlled Row Farming method with regard to the plant cultivation and ecological effects, the question of economic viability also arises. How does the increased financial expenditure for technology, labour and...

CRF trial 2024/2025: Winter barley

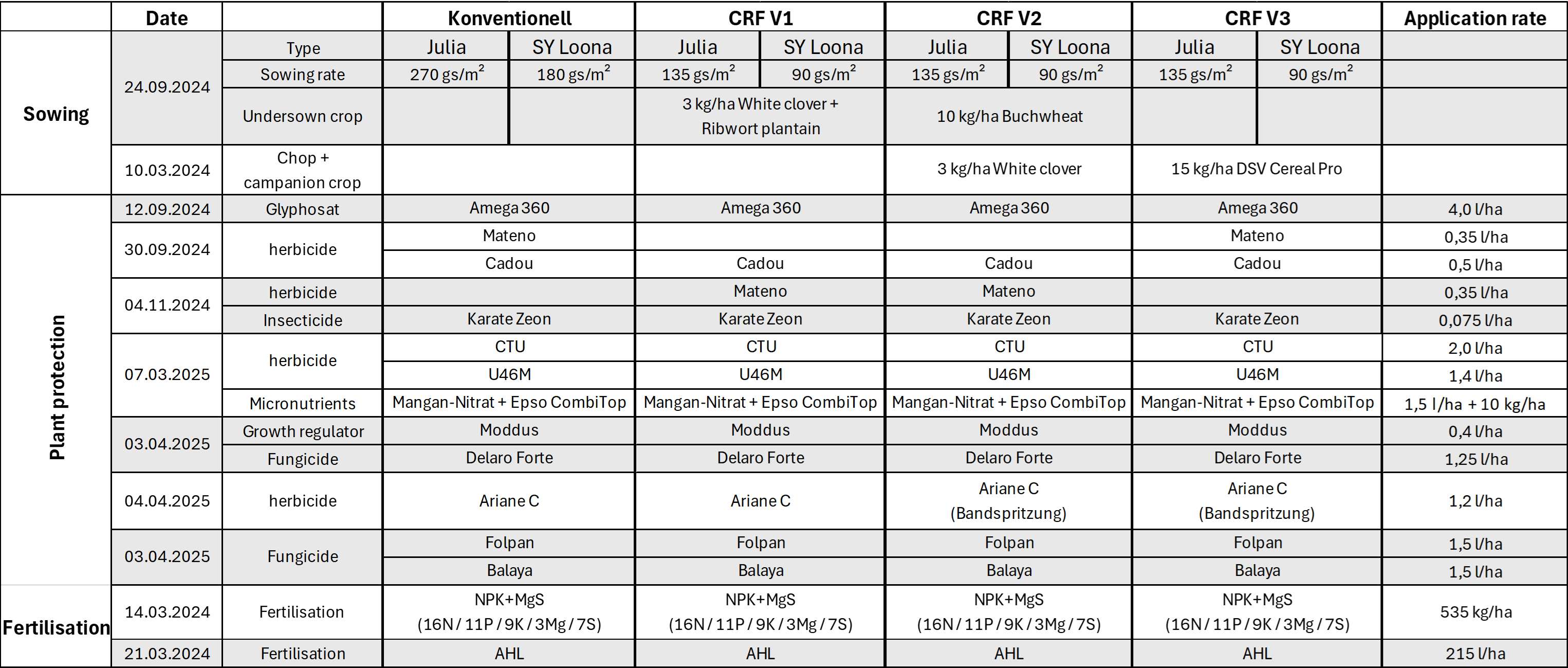

As part of our CRF trial in 2024/25, we compared two different variety types of winter barley: the pure line variety DSV Julia and the hybrid variety SY Loona. In addition, we tested different dates for sowing companion crops. The previous crop was winter rape.

Trial design

The barley was planted at the end of September using the mulch sowing method. A 6 m Avant with FTender 2200 was used for sowing. In the conventional variant, normal seed rates were selected (270 gs/m² for the Julia variety and 180 germinable seeds/m² for the Loona variety), while seed rates were reduced by 50% in the CRF variants. The sowing depth was three centimetres.

In the CRF V1 and CRF V2 variants, we sowed companion crops in parallel with the barley. We sowed 3 kg/ha of ribwort plantain and white clover in the CRF V1 variant. 10 kg/ha of buckwheat was sown in the CRF V2 variant. In the CRF V3 variant, DSV TerraLife CerealPro was sown with a hoe in spring 2025. Due to heavy weed pressure in autumn caused by chickweed, a herbicide against dicotyledonous weeds was applied, meaning that the companion crop was also controlled. Therefore, we also sowed 3 kg/ha in the CRF V2 variant with a hoe in the spring.

For plant protection (UF1302), the variants sown without a companion crop were treated with Mateno + Cadou in early post-emergence. The variants with the companion crops were initially only treated against grasses. Due to heavy weed pressure, measures had to be taken at the beginning of November. Follow-up treatment was necessary in the spring. This was carried out with full area coverage. Further treatment was necessary as the common ragwort had not been sufficiently controlled. This was carried out as a band application in the CRF V2 and CRF V3 variants.

The fungicides and growth regulators were applied using the same strategy across all variants and were applied with full area coverage.

The trial was fertilised with mineral fertilisers in liquid and granular form. Fertilisation was carried out with full area coverage. In addition, micro-nutrients such as manganese, zinc and magnesium were added as fertilisers.

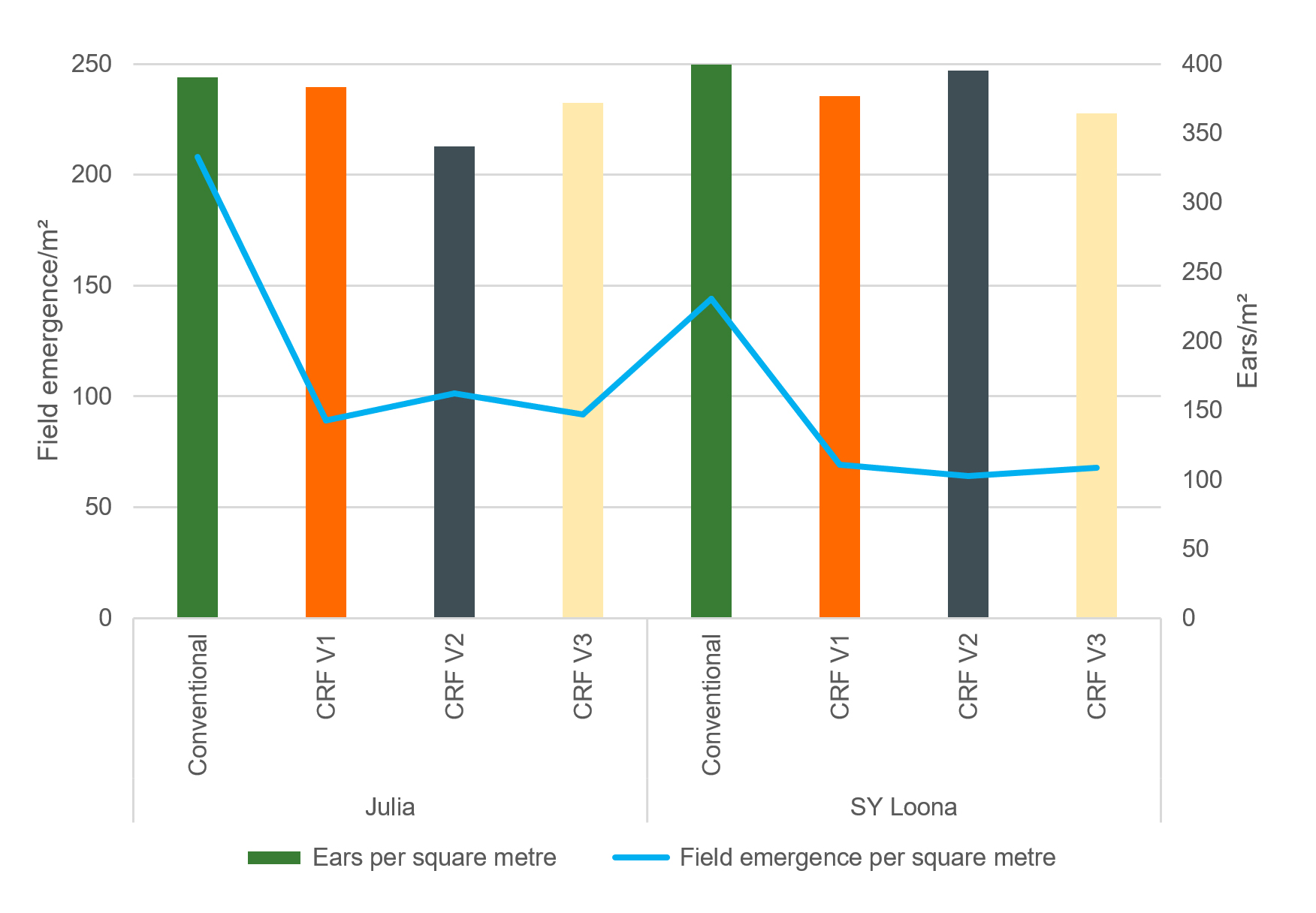

Observations in the field

Field emergence was at a similar – expected – level for both varieties. Despite relatively early sowing of the cereals, the companion crops were unable to develop sufficiently to suppress weeds. Therefore, there was extremely strong pressure from chickweed in these variants. Sowing the companion crop in spring was also a major challenge. The very dry conditions from the beginning of March to the end of May provided ideal conditions for using the hoe. However, these conditions also pose a challenge for the emergence of companion crops. Due to the dry conditions, plants emerged only sporadically and in insufficient numbers.

Ripening and yield

The ripening of both varieties was fairly identical, so that the crop could be harvested with moisture levels of 12.6% and 12.7% respectively.

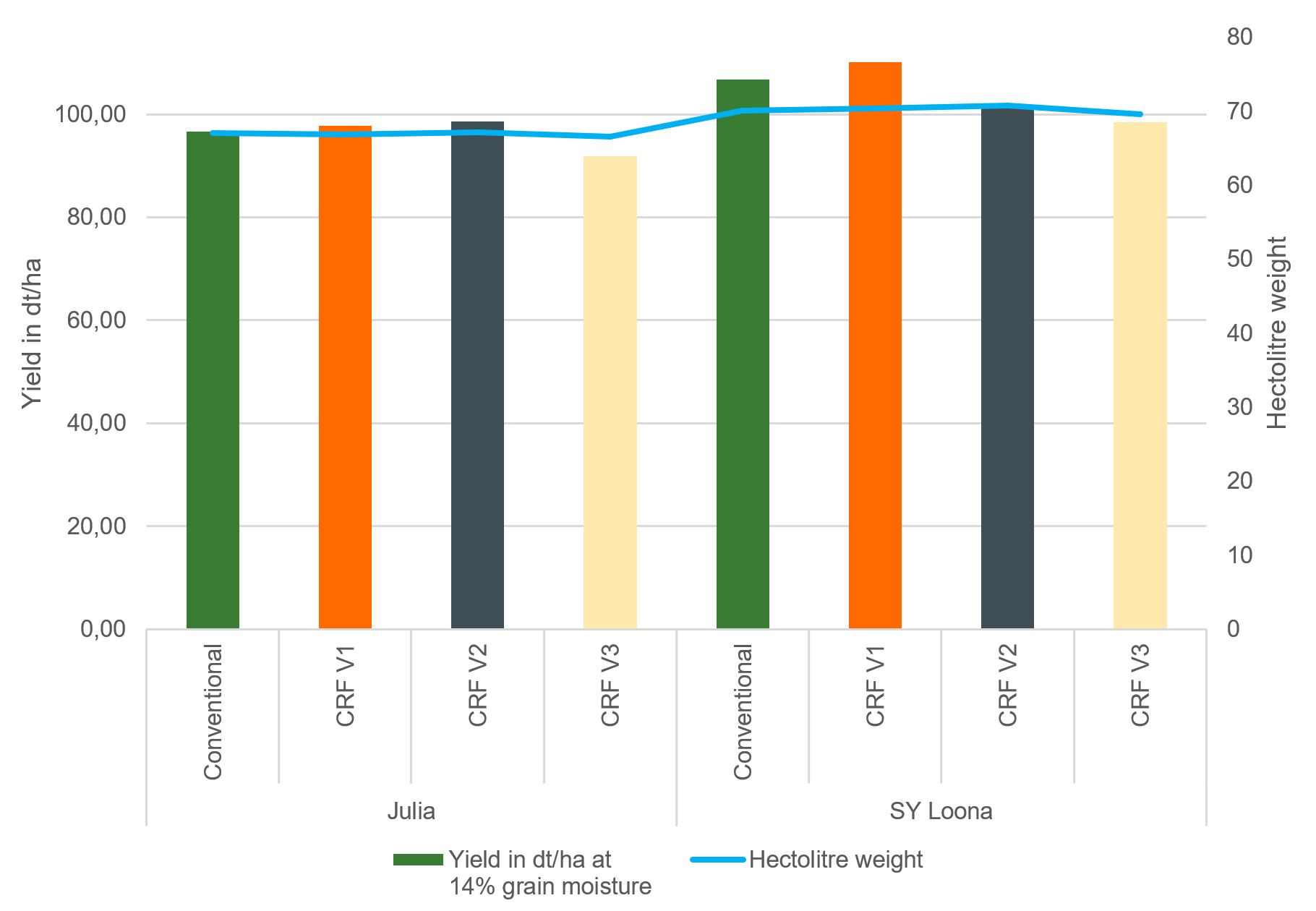

In terms of grain yield (14% grain moisture), Loona achieved the best result in CRF V1 with 110.1 dt/ha – just ahead of the conventional variant of the same variety. Julia's yield was broadly similar across all variants, with CRF V2 leading the way at 98.6 dt/ha.

All varieties were close together in terms of hectolitre weight. Loona showed slight advantages in the CRF-2 variant. This confirms the assessment result that the hybrid barley was well able to compensate for the lower sowing rate through stronger tillering. In addition, it can be seen that the hybrid barley achieved a slightly higher yield due to its slightly higher hectolitre weight.

Cost-effective:

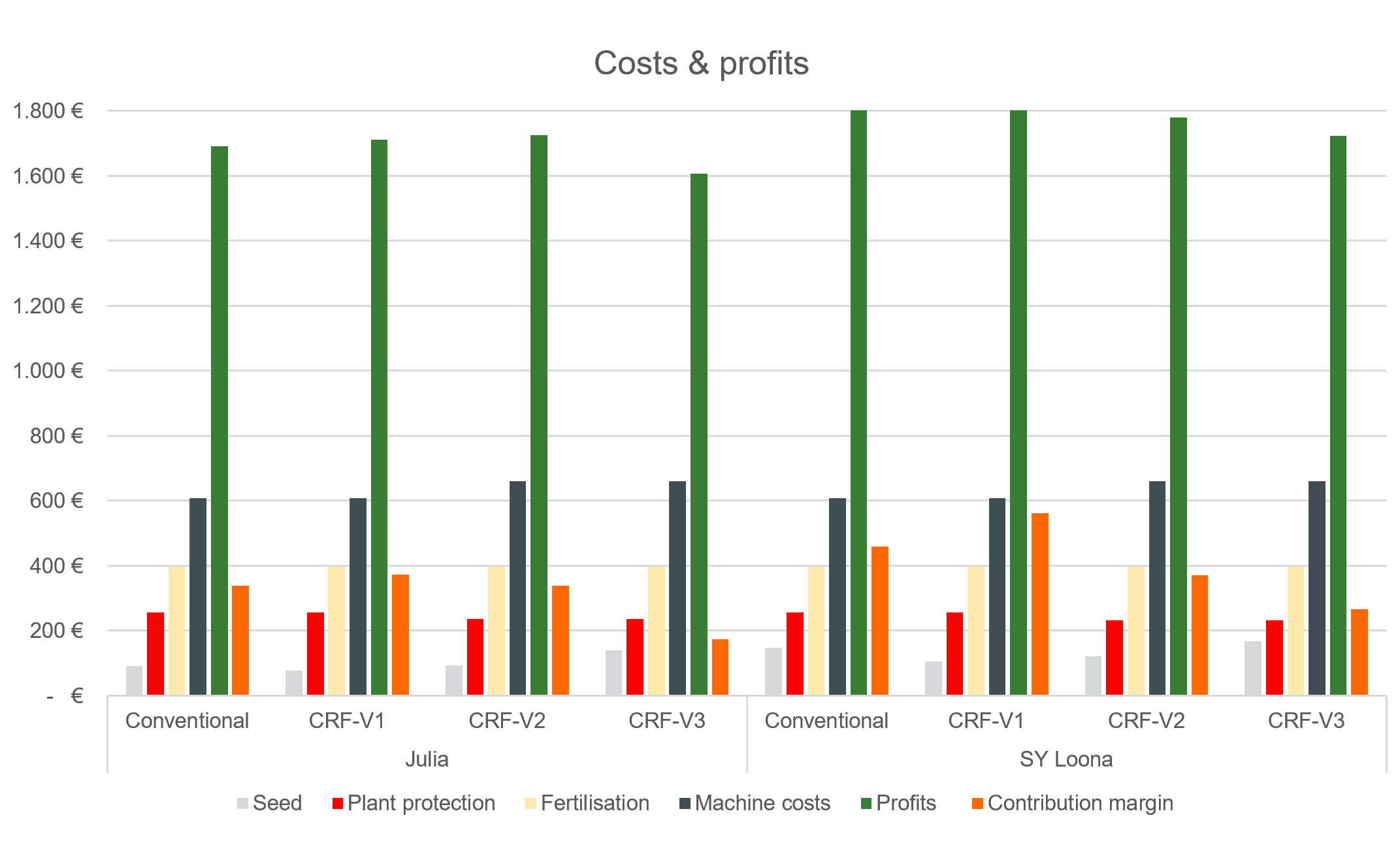

To calculate profitability, we have assumed a barley price of € 17.50/dt. The costs for the implements are taken from the data records of the machinery ring, and the costs for the inputs are the prices actually paid.

The highest total costs were recorded in the CRF V3 variant, as the seed costs for the diverse companion crops were highest here. The slightly higher costs for hybrid seeds are also reflected in the total costs, but the slightly higher seed costs are clearly offset by the higher yield. The CRF V1 variant of the SY Loona variety was the most economically viable option, with a contribution margin of € 561/ha. Similarly, the CRF V1 variant was the most economical option for the Julia variety, at € 374/ha.

Conclusion:

The trial year 2024/2025 showed that the choice of variety had an impact on crop development and that low sowing rates could be compensated for with strong compensation types. This is also reflected in the yield, with the hybrid barley producing an average yield that is approximately 8 dt/ha higher. In addition, the trial year showed that research is needed into the establishment and care of companion crops.

Amazone catch crop trial

From the undersown crop to the catch crop: White clover in the CRF

White clover is an interesting plant for the undersown crop in the CRF method. This was demonstrated by our cultivation trial in 2023/2024. We also tested whether a robust and fast-growing catch crop can be developed from the undersown white clover. The results are very promising.

Sowing together with the wheat

In autumn 2023, we sowed winter wheat and white clover in a single pass using the 6 m Avant with FTender 2200 and a double conveying system with RoTeC Control coulters. The structured sowing enabled targeted placement of the seeds, meaning that both seed types had optimum germination conditions.

The undersown crop was initially slow to establish. The field emergence was good in spite of the late sowing at the beginning of October, but wet and cold weather made for slow development. The white clover had also not yet been adequately established in spring 2024. At the onset of the warmer weather from the beginning of April, growth got off to a good start. After a pass with the knife roller in May, the clover filled the row when the wheat was harvested.

After the harvest: Only mulching

After the harvest at the beginning of August, we mulched the area once with the undersown white clover. On the other sections, one of which was cultivated conventionally and the other two using the CRF method with and without undersowing, soil tillage was carried out in two passes, first with the Catros+ 6003 – 2TS compact disc harrow and then the Cenius 3003 Super cultivator.

During sowing of the catch crop on the other areas in the middle of August, we could already see almost complete crop closure on the white clover area.

A comparison of the sowing variants three weeks later showed the following:

- The white clover clearly had the edge with regard to the suppression of volunteer grain and weeds. We had a clean clover crop in autumn.

- There was a uniform field emergence in the drill sowing variant and volunteer grain and weeds were suppressed to a large extent.

- Catch crops sown using the bio strip-till method struggled. Although the field emergence was very good here, the subsequent suppression of the volunteer grain clearly left much to be desired. The suppression performance in the legume row was poor as a result of the structured sowing. In this respect, the plant species should be reconsidered in the future.

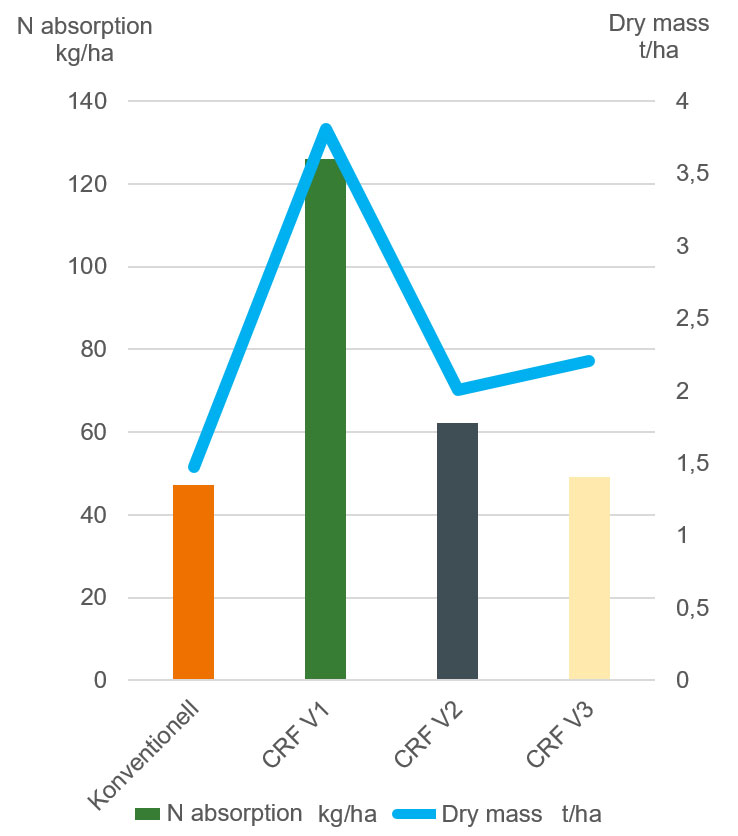

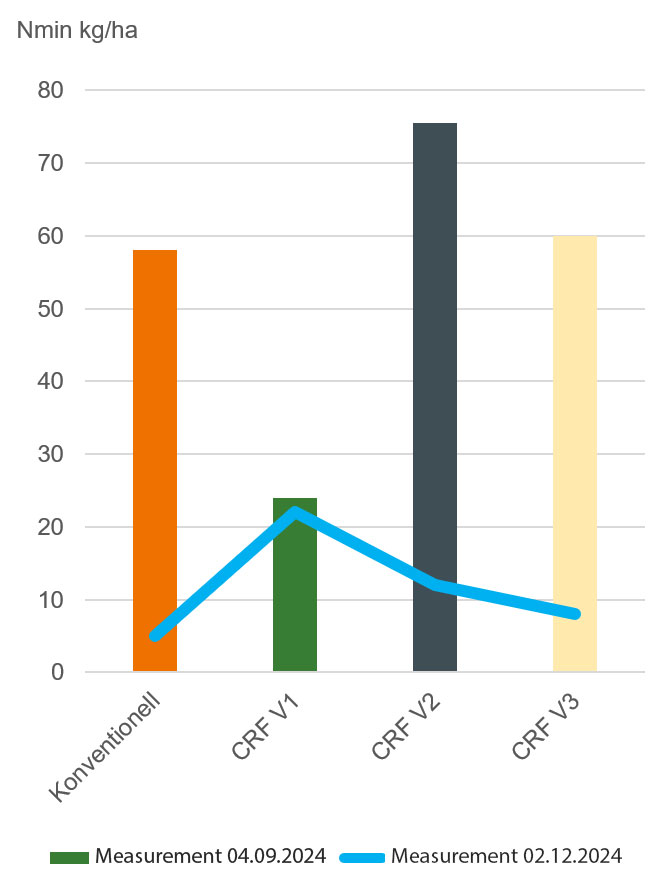

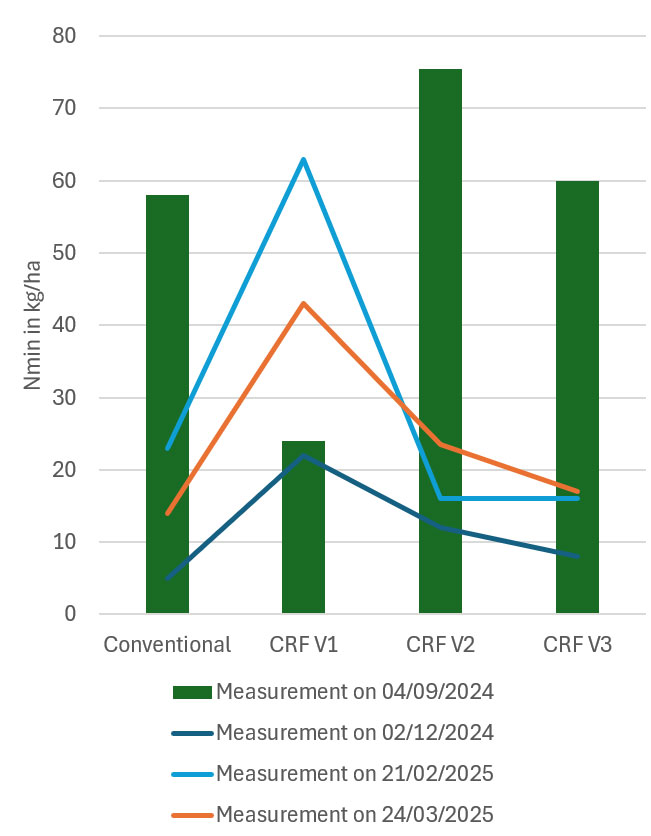

Nitrogen in the soil

In addition to crop development, we were interested in the question of whether there are any differences in the Nmin dynamics of the individual methods in the catch crop trial. In the first measurement in September 2024, the white clover had the lowest Nmin values compared with the other variants. The intensive soil tillage probably pushed forward the mineralisation in the other variants to a large extent.

This changed in December. Whereas the Nmin values in the white clover area remained constant, they had considerably decreased in all other variants. With its high dry mass, the white clover probably absorbed a considerable amount of N, whereas the leaching in the other variants as a result of high precipitation over the entire autumn as well as the absorption of N by the catch crops caused the decrease.

Reduction in organic fertilisation

Against the background of the high Nmin values, the question is raised as to whether organic fertilisation in the clover variant can be reduced. We will therefore continue to consider the development of the Nmin dynamics in the soil.

Turning over before sowing maize

We used a disc harrow to cultivate the white clover area and then carried out a pass with the plough before sowing maize in spring 2025. This allowed chemical-free turn over of the clover.

Conclusion

In our view, the development of the undersown white clover into the catch crop was successful. Owing to the abundant biomass upgrowth and rapid crop closure, both volunteer grain and weeds could be effectively suppressed. Other factors include the low N losses and the high N absorption, which set the white clover apart from other catch crops.

Other advantages are the long period of soil rest of 18 months, which is conducive to humus development, as well as the reduced extent of work compared to the other methods as a result of a reduction in the number of working passes.

Sowing of the companion crop in autumn – what benefits does this have for wheat?

Sowing of the companion crop in autumn – what benefits does this have for wheat?

We grew wheat using the CRF method in the cultivation year 2023/2024. Three different companion plants/undersown crops were tested in the trial. The wheat was managed using the conventional cultivation method on a fourth part-area for comparison.

First of all, the following should be noted: The cultivation year posed major challenges for us. Firstly, the establishment of the companion plants was hampered as a result of the extremely wet conditions present during sowing. Secondly, the wheat had to struggle with a severe brown rust infestation due to the weather and the variety.

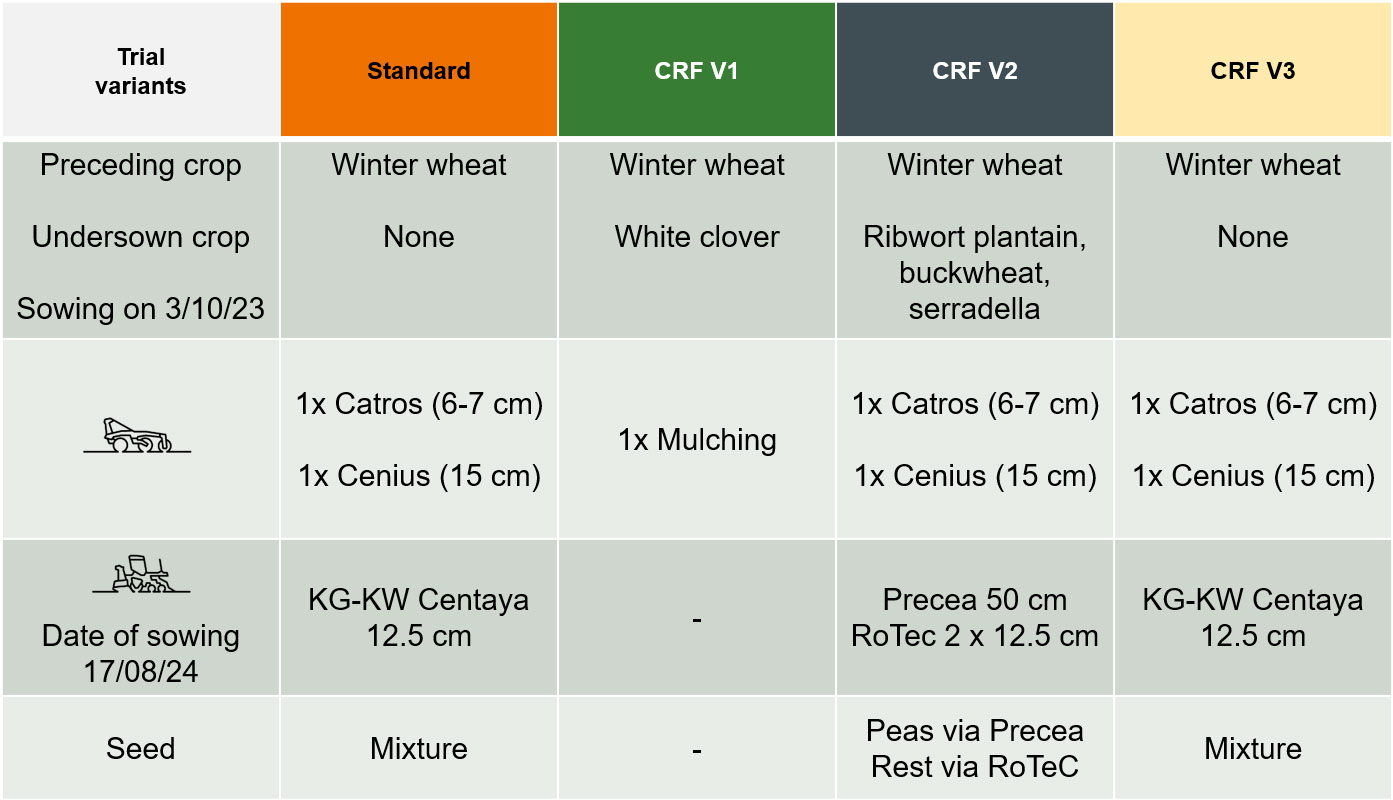

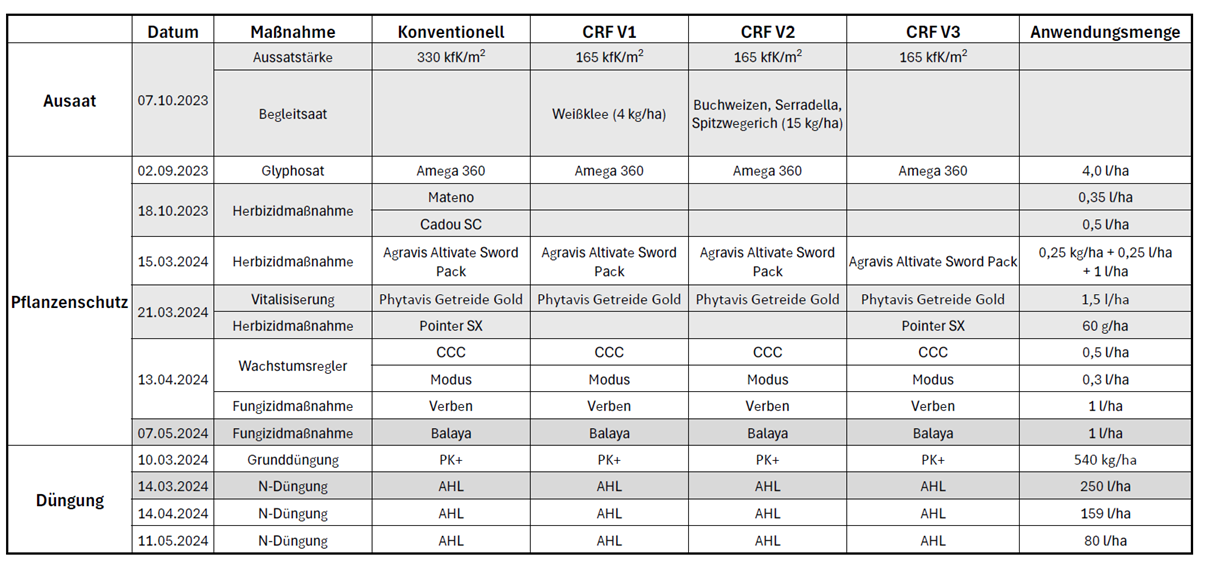

Trial design

After conservation soil tillage had been implemented, we used the 6m Avant with FTender2200 to sow wheat of the variety DSV Debian, with a sowing rate of 165 seeds/m² in the three CRF variants (double row, row width 50 cm) and 310 seeds/m² in the conventional variant with a row width of 12.5 cm at the beginning of October.

We sowed white clover in the variant CRF-V1. A mixture of serradella, buckwheat (both frost-intolerant) as well as ribwort plantain (hardy) was used in the CRF-V2 variant. The mixture M2 Plus (dt. ryegrass, white clover, crimson clover, timothy grass, bird's-foot trefoil, ribwort plantain, phacelia, linseed and camelina) should have been sown at the hoeing pass in spring for the variant CRF-V3, but the soil was too wet.

For plant protection (UX5201 Super), the application plan provided for a herbicide application in autumn only for the conventional section. A herbicide application against grasses was carried out on all areas in the spring. In addition, we carried out a herbicide application against dicot weeds in the conventional variant and in CRF-V3.

Sowing with the subsequently wet weather conditions gave the companion plants a poor start in CRF-V1 and CRF-V2, in spite of optimum sowing quality. They found it hard to establish themselves and therefore could not provide adequate crop closure, meaning that there was no shading of the soil.

As a result, chickweed and annual meadow grass, the typical weeds for this location, continued to flourish in the spring. Only the ribwort plantain in the mixture for CRF-V2 managed to develop well – however, this was clearly not enough to have a positive effect on the weed development.

Owing to the high weed pressure, we were forced to carry out a full-area herbicide application in the CRF-V1 and CRF-V2 variants in the spring. A grass herbicide was used here, but it did not adequately control the grasses in the companion crop. Another herbicide against two-leaf weeds was used in addition to the grass herbicide in the CRF-V3 variants and the conventional variant.

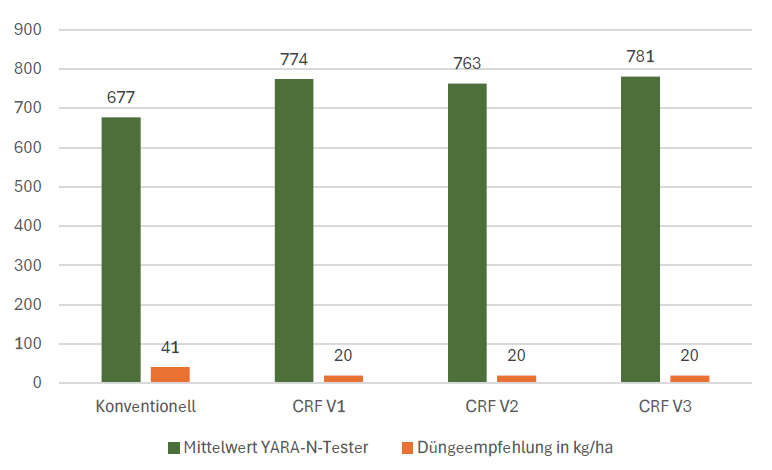

Successful fertilisation on the row

Application of the N fertiliser on the row in the CRF variants proved to be effective; according to the measurement with the Yara N-Tester, the plants had a higher N concentration than the plants in the conventional section. The resulting fertilisation recommendation was 50% lower.

What happened in the field: Diseases

While we tended to find septoria in the crop in the spring, a severe brown rust infestation occurred in the later stages of the growing season in spite of intensive fungicide treatment. In this context, it was determined that the rust infestation in the conventional variant was only half as high as in the CRF variants, with 17–18 % of leaves infected. The high N supply of the plants provided by the placement of liquid fertiliser on the row probably had an impact on the disease susceptibility here.

This results in the following question for us: Should fertiliser be applied differently or in lower quantities in CRF variants? A general reduction in the application of fertiliser is one of the objectives which we have set ourselves in Controlled Row Farming. This point is currently being further investigated as part of a master's thesis and also in a fertilisation trial in winter barley.

Companion crop at harvest

The first pass with the knife roller took place in May. Overall, the shredding was good. The cutting result was better in the harder plants such as ribwort plantain than in the soft plants such as clover, whereby the shredding here can still be considered adequate.

The clover and the ribwort plantain stood nicely in the row as a companion crop at harvest. With a high cut of 20 cm, we had no problem cutting the wheat.

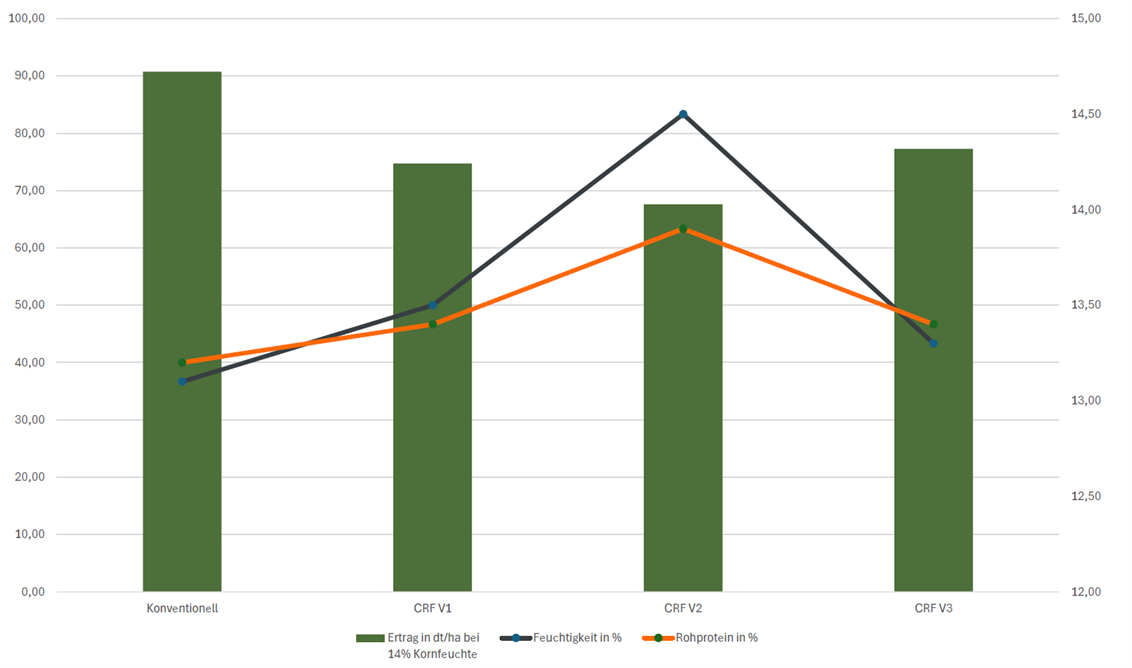

What about the yield?

The conventional variant clearly provided the highest yield in this cultivation year. Over the last few years, the plants grown in the CRF method could compensate for the lower number of ears with a higher thousand-seed weight. This year, however, they were unable to exploit the higher nutrient supply and the larger space because of the disease pressure.

The conventional variant came out in front in the yield evaluation this year.

Consequently, the conventional variant was also significantly ahead of the CRF variants with respect to net profits and was the only one to generate a (meagre) contribution margin under the difficult conditions.

Conclusion

In the next trials, we will focus our attention on whether a reduction in the amount of fertiliser is possible in the row-specific application and, as an alternative, whether a different distribution of the fertiliser application gives rise to positive effects. Furthermore, we will examine how the plant protection strategy should be adapted to the higher N supply of the plants. The final application with drag hoses in the taller crop is not optimum, because the hoses were pulled over the crop in some cases. This caused chemical burns to the plants.

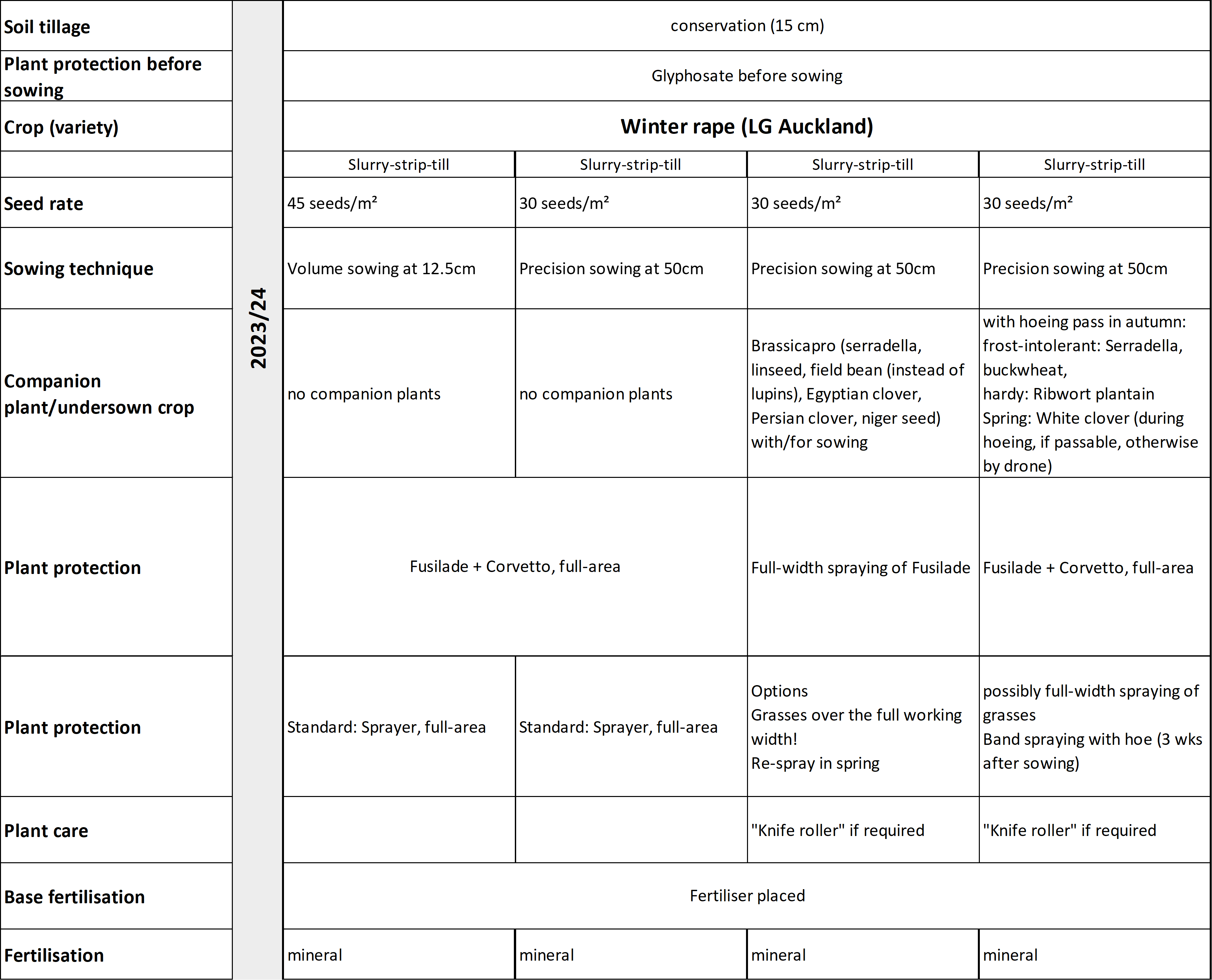

CRF trial: Rape

In addition to wheat, we grew rape as a second crop in 2023/2024 using the CRF method. However, the trial did not yield any conclusive results as a result of a heavy pest infestation, which is why we only give a brief summary here.

Trial design

Whereas the Centaya 3000 Super + rotary cultivator was used for sowing the conventional variant, we used the Precea 6000-2FCC for the CRF variants. The undersown crops were sown separately for the last time this season (Centaya 3000 Super + rotary cultivator). This is now possible in a single pass with our trial machinery.

No companion plants were sown in the CRF-V1 variant. The BrassicaPro mixture with serradella, linseed, field bean, Egyptian clover, Persian clover and niger seed was also applied during sowing in CRF-V2. Serradella and buckwheat were sown in CRF-V3 during the hoeing pass in autumn. In addition, white clover was sown by drone in spring, since a second hoeing pass in mid/late March was not possible due to the weather conditions.

The companion plants in CRF-V2 profited from the early sowing and were well established before winter. This was not the case for the plants sown in mid-October in CRF-V3. These developed poorly or not at all or were immediately killed by frost. The clover also left much to be desired, with poor emergence after sowing.

We used the UF2002 with FT1001 and the ZA-V4200 for the fertilisation measures. The crop protection measures were carried out with the UX5201 Super.

Development in the field

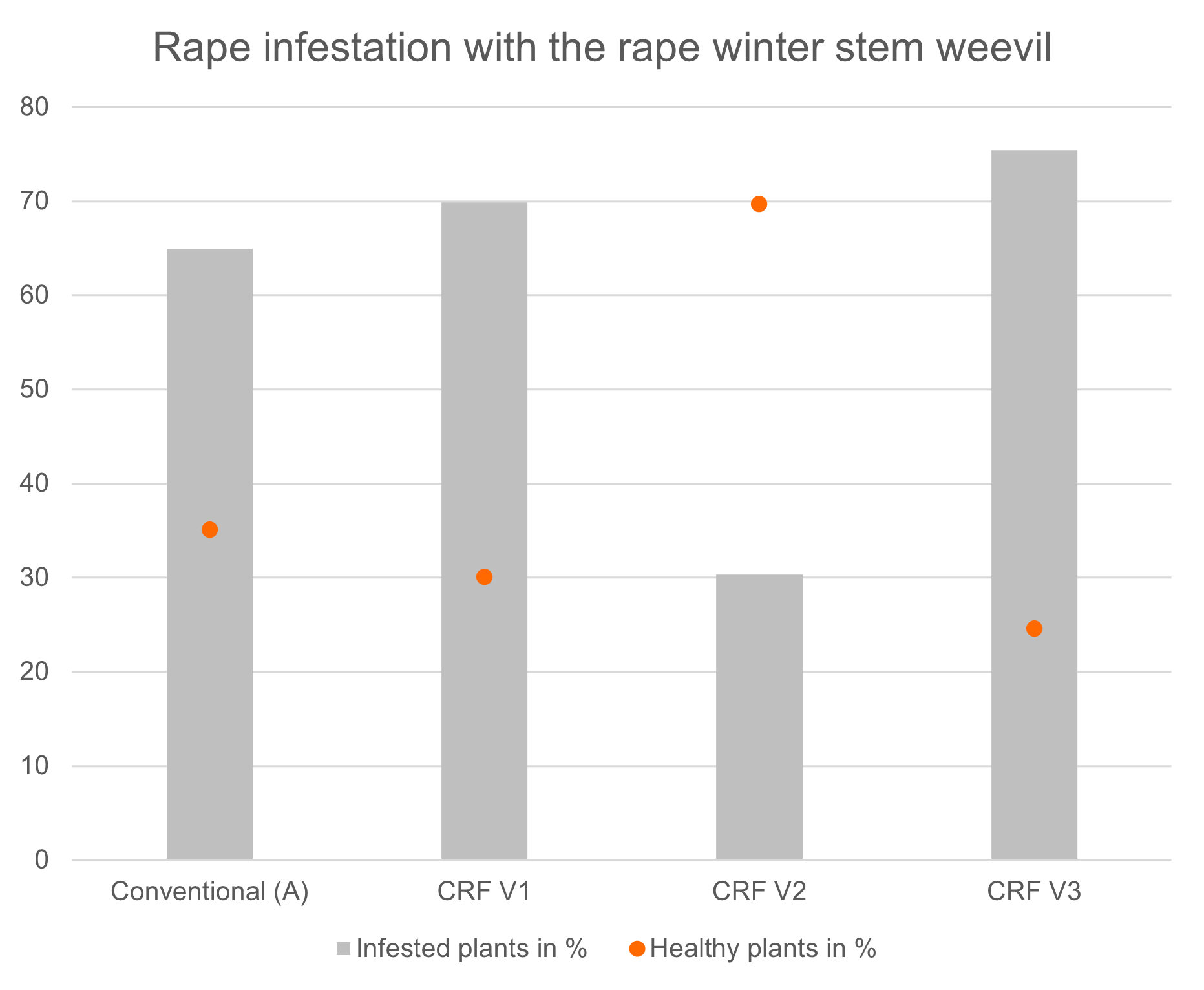

The rape had to contend with various adverse events. Development in autumn was significantly affected by high rainfall after sowing. A heavy rape winter stem weevil infestation then occurred in autumn – in spite of an insecticide measure. Depending on the variant, up to 75 % of the plants had been affected by the end of March. The significantly lower infestation in CRF-V2 is worth mentioning. Undersowing with DSV Terralife BrassicaPro obviously had a positive effect here – the companion plants probably attracted the interest of the rape winter stem weevil, thereby “distracting” it from the rape.

As can be seen in the assessments, the infestation was very high in all variants. It is conspicuous that the infestation was up to 57% lower in Variant C with the BRASSICAPRO mixture than without a companion crop. This suggests that companion plants distract the rape winter stem weevil and therefore support the development of the rape.

The significantly weakened crop was subsequently unable to develop well. Furthermore, the plants had to contend with extreme chickweed pressure in CRF-V1. The weed established itself so well that it pulled down the rape and provided pigeons and other birds with an ideal landing space.

Additional challenges

We recorded a significant increase in damage done by mice in CRF-V2. It appears that the rodent pests found more places to hide due to the ground cover. Mouse poison was put down as a response. The additional placement of raptor perches proved successful, with birds of prey regularly sitting at the edge of the field after just two weeks.

Delayed development was observed in the CRF-V3 variant. This is attributable to the hoeing pass in autumn, which was carried out under wet weather conditions and led to soil capping.

Harvest and yield

At 25.33 dt/ha, the yield was average for the region. However, we have dispensed with further evaluations as a result of the significant weakening of the crop. The only thing to mention here is that the grain yield was best in CRF-V2, while CRF-V1 suffered high yield losses due to chickweed and damage done by pigeons.

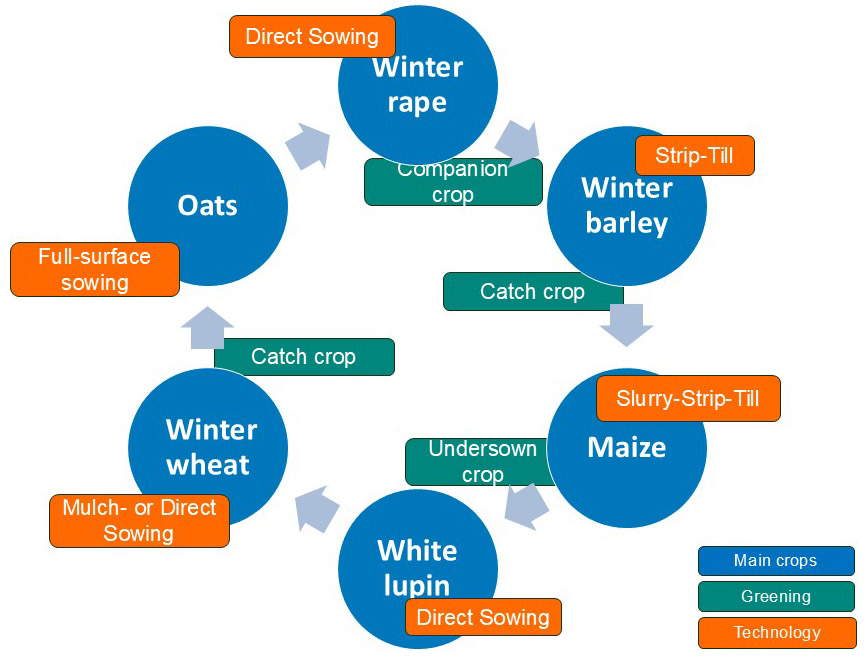

CRF crop rotation – How could crop rotation be implemented in the CRF arable farming system?

The second arable farming dialogue took place during this year's AMATECHNICA at AMAZONEN-Werke. The Controlled Row Farming (CRF) farming concept was the main topic of the event. Precision Farming trials and a comparison of direct vs. mulch sowing at Gut Wambergen were also presented.

The CRF farming concept is seen as an exciting approach for possible future challenges, such as the elimination of plant protection agents, an increase in biodiversity and more efficient fertiliser use. Crop rotation is a central component of the future development of CRF. Various steps were therefore defined. The "basic concept" serves as an introduction to the CRF farming concept, whereby implementation in individual main crops can be carried out with existing machine equipment for the most part. The initial integration of companion crops in rape cultivation can be mentioned as an example. The "biodiversity concept" means maximising plant diversity with the acceptance of reduced yields. Under the circumstances, implementation is only realistic with funding programmes.

The "target concept" means that the complete cultivation system is oriented towards CRF, so that the row widths are standardised, fertiliser is placed in the row and companion plants are sown in as many crops as possible. Furthermore, the machine equipment is tailored to the CRF system. The key premise of the "target concept" is that it provides yields at a high and stable level. The yields should be at the same level as those obtained in conventional agriculture.

Possible crop rotations were discussed in an analysis of the overall arable farming system, in order to take phytosanitary, agricultural and economic aspects into account. A possible crop rotation for the target concept is presented in the following.

The rotation starts with rape, which is grown with a companion crop, e.g. TERRALIFE BRASSICA Pro. This is followed by winter barley. The companion crop mixture has the advantage that the soil between the precision sowing is covered, and the diversion of harmful insects, such as the rape winter stem weevil, could be observed. The winter barley is sown into the rape stubble to maximise the positive effect of the preceding crop. In addition, the winter barley has a higher N absorption capacity in autumn than winter wheat. Maize is grown the following spring after a structured catch crop. The structured catch crop enables legumes to be grown in the row of maize, and a higher N concentration can be found in the soil in this row. This means that the maize has to be supplied with fewer nutrients in spring. Soil conditions permitting, the maize can be grown in the slurry-strip-till process to increase the N efficiency. An undersown crop is sown in the maize to provide sufficient vegetation over the winter after the maize harvest. This enables white lupin to be directly seeded the following spring. Winter wheat is grown in the autumn via mulch or direct sowing after the white lupin has been harvested. The wheat can make excellent use of the preceding crop effect, such as the good root penetration and the nutrient supply of the white lupin. Oats are the last element in the crop rotation. They are grown as a recovery crop and are the only crop in the rotation which is sown across the full working width. The reason for full-surface sowing is that this enables e.g. any ground undulations to be compensated for, and weeds and grass weeds can also be systematically suppressed.

Apart from oats, the last element of the crop rotation, all crops are grown in the CRF system with a row width of 50cm. Cereal cultivation, which takes place in a double row, is the exception. Furthermore, the question arises as to whether all measures should be implemented in the row or whether crop protection measures such as grass weed control should be implemented with full area coverage, in order to prevent resistance. We had positive experience e.g. with row-specific N fertilisation in wheat, since higher N absorption could be measured. Further results will be presented later. Another aspect which needs to be examined is the intensive cultivation of legumes, both as a main crop and a component of undersown and companion crops, as well as catch crops.

If additional crop rotation elements such as sugar beet or potatoes are considered, the crop rotation will obviously have to be redesigned, and the question as to whether and how these crops can be integrated in a CRF crop rotation also arises.

The fundamental objective of the CRF cultivation system must be that it is financially self-sustaining through high yields and lower costs for inputs, thereby making arable farming more resilient to the effects of the weather as a result of a healthy and vital soil life. The "target concept" will therefore continue to be pursued in the future.

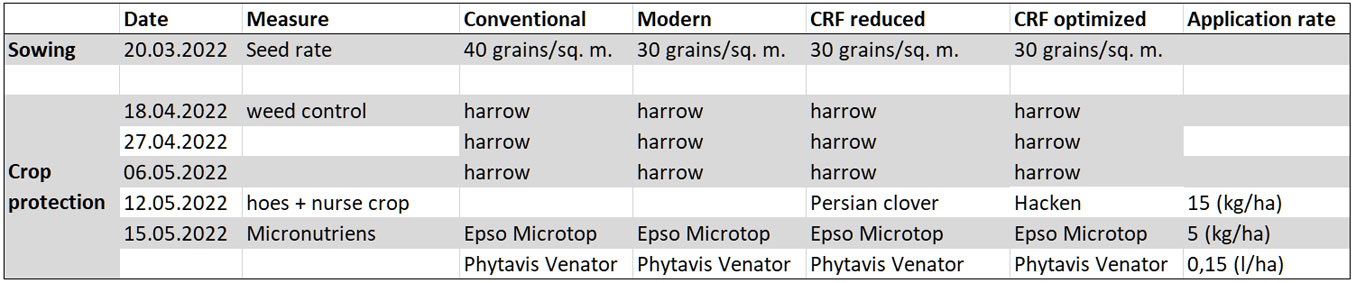

Cultivation year 2022 – The field bean is also adaptable

In addition to the demo trial at Gut Wambergen, a randomised field trial was also conducted in the region in cultivation year 2022, in order to provide a more detailed analysis of the CRF concept. A trial site with three repetitions on a sufficiently large area was needed to clarify in detail how the field bean behaves in the CRF system. The trial was carried out as part of a master's thesis supervised by the University of Applied Sciences, Soest.

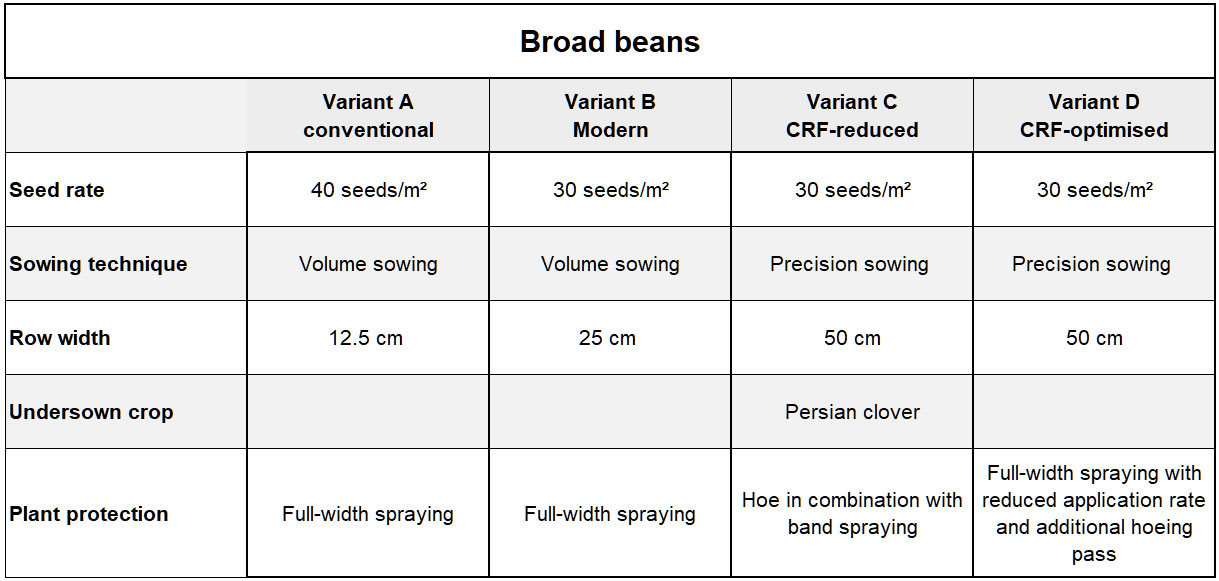

The field bean "Tiffany" was sown on 20.03.22. The sowing rate in the conventional variant was 40 germinable seeds/sq, with a row width of 12.5 cm. The theoretical seed gap within the groove is 20 cm. Only 30 seeds/m² were sown in the Modern variant with a double row width (25 cm). The theoretical seed gap within the groove is 13.3 cm in this case. These two variants were sown with an Amazone “Centaya 3000 Super“ standard drill combination.

The two CRF variants with a row spacing of 50 cm were sown with the precision air technology of the “Precea“. 30 seeds/m², with a theoretical seed gap within the groove of 6.7 cm, were also sown in the CRF variants.

Field bean in the variant Standard 12.5 cm (BBCH 28 on 12.05.2022)

Chemical weed control could not be provided in the pre-emergence in March owing to impassable ground conditions and persistent rainfall. Purely mechanical weed control was selected as an alternative instead. Three measures were carried out with a harrow in each of the four variants between BBCH 13 and 20. These were carried out at intervals of approx. 9 days.

A hoeing machine could also be used in the two CRF variants owing to the 50 cm row spacing. This was carried out in BBCH 28. The undersown crop was also sown between the rows of field beans during hoeing in the CRF-reduced variant. Further crop protection measures could be dispensed with owing to the warm and dry weather conditions in the following weeks. All four trial variants therefore managed completely without chemical plant protection!

Subsequent crop management is restricted to a single application of micro-nutrients in combination with a substance which provides protection against insect pests. The application was uniform across all variants.

The undersown crop was sown in the CRF-reduced variant during hoeing on 12.05.22. 18 kg/ha of Persian clover was sown between the rows of field beans.

The Persian clover became well established in the crop, but its development was inhibited as a result of the increasing drought and shading by the beans.

Development of the Persian clover four weeks after sowing (10.06.22)

There were no differences between field emergence and plant height in the further crop development of the variants. The spatial variability caused by the different variants is reflected in the rating of the pods per plant.

The following graphic shows the number of developed pods per plant. It can clearly be seen that the variants with a reduced sowing rate and larger row spacings tillered more densely and developed more pods.

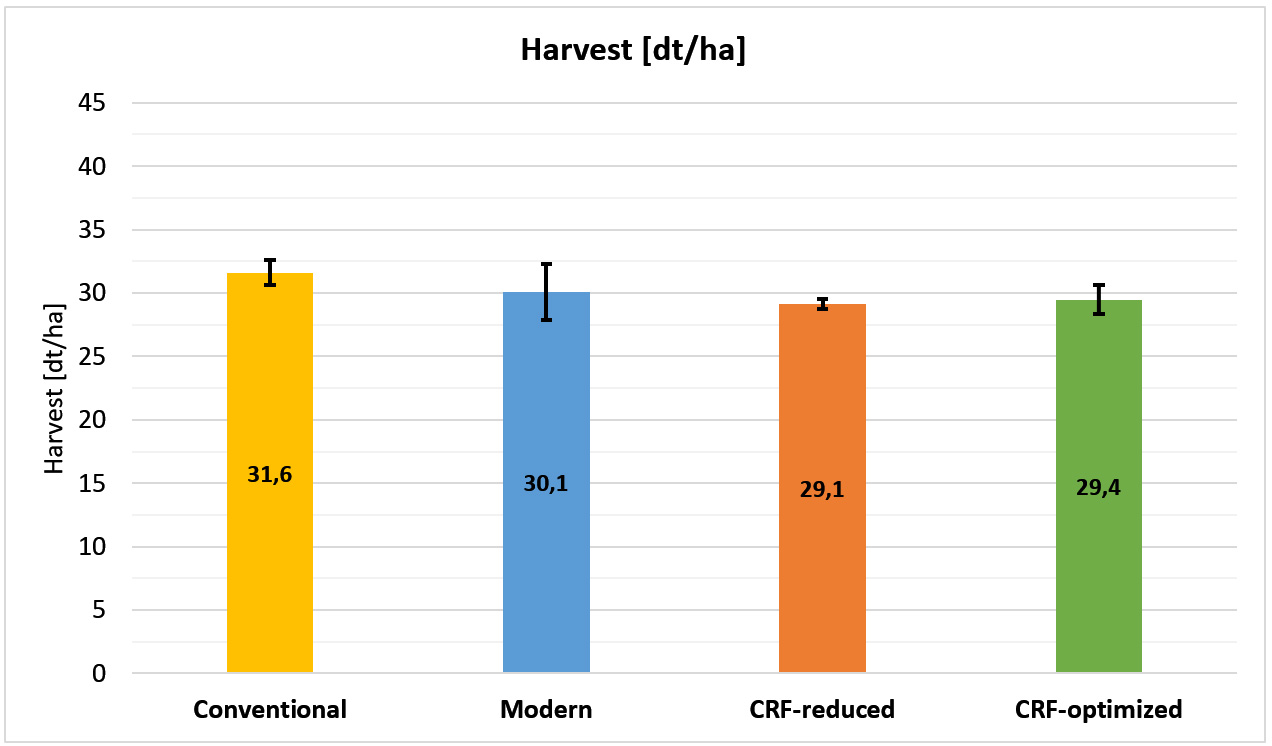

The field beans were harvested on 31.07.22. The individual repetitions were harvested by means of core threshing and weighed. An average yield of the variants of approx. 30 dt/ha in an extremely dry year was slightly below average for the region.

On the whole, the yields are very similar. Although the Standard variant had the highest yield with 31.6 dt/ha, there is no significant yield difference with a least significant difference of 4.4 dt/ha.

In addition to the results from the field, samples from each variant were examined in the laboratory. The thousand seed weight was relatively constant at 480 to 490 g. The crude protein content of the samples was also very close in all trial variants at 27.7 to 27.9 %. Even if the values have not been statistically checked, we can say that the qualities are consistent. The consistent yields in the field trial suggest that the yields of the lower sowing rates are compensated for by an increased number of pods per plant.

The undersown crop of Persian clover had no negative effect on the yield in the CRF-reduced variant. As might be expected, the competitive vigour of the clover sown at a later date combined with the extremely dry weather conditions was limited.

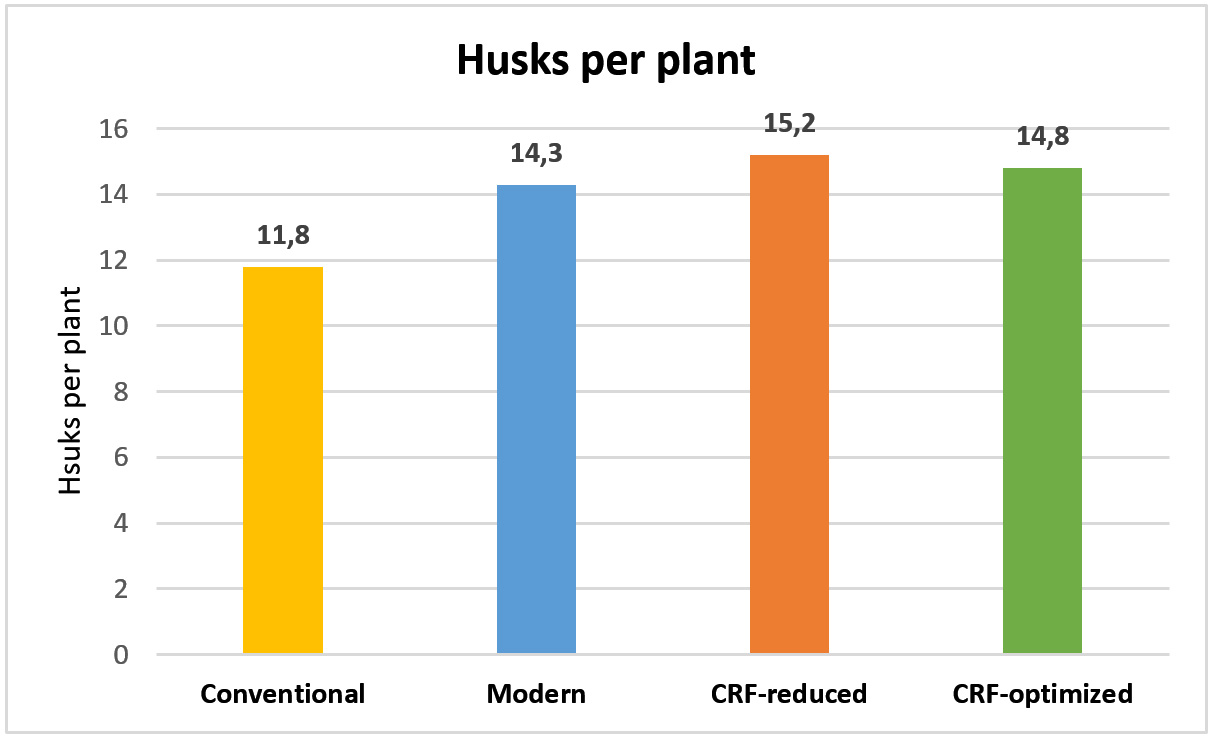

Giving priority to biodiversity – how much yield did it cost?

After we treated the companion plants relatively defensively in the first years, we wanted to give priority to biodiversity for the winter wheat 2022/2023. The sowing of wild herbs in the CRF system without the application of herbicide in the intermediate area was a benefit for wildlife but a challenge from the point of view of the conventional farmer.

The winter wheat variety Chevignon was sown with the Centaya rotary cultivator drill combination with RoTeC coulters on 12th October 2022.

The variants from recent years were selected:

- Conventional (A) with 12.5 cm row spacing and 330 seeds/m2 – with the usual full-width spraying

- Modern (B) with 25 cm row spacing and 165 seeds/m2 – with the usual full-width spraying

- CRF-reduced (C) with 2 x 12.5 cm at 50 cm distance to the next double row and 165 seeds/m2 – with companion crop and band spraying

- CRF-optimised (D) with 2 x 12.5 cm at 50 cm distance to the double row and 165 seeds/m2 – with the usual full-width spraying

The two seed tanks and the two distributor heads enabled a conservation mix to be sown simultaneously in a double row between the two double rows of wheat in variant C (CRF-reduced) (seed rate: 10 kg/ha). This companion crop was a flowering wild plant mixture with 21 different components such as corn flower (Centaurea cyanus), ribwort plantain (Plantago lanceolata) or red clover (Trifolium pratense) from Rieger-Hofmann GmbH.

The companion crop established itself very slowly in the cool and wet autumn. On the other hand, some undesirable weeds appeared in the wheat crop. As a result, the first herbicide application was provided on 02nd December with 30 g/ha of Pointer SX and 3 l/ha of Boxer. A full-area application was carried out in variants A, B and D, whereas the plant protection measure was applied as a band spray in variant C. With a band width of 20 cm, we were able to achieve herbicide savings of 60 %.

Additional herbicide applications were carried out on 18th March with 0.2 l/ha of Husar Plus and on 25th April with 50 g/ha of Potacur SX, so that the wheat could develop in the spring without disturbance. In variant C, the wild plant mixture was developing very well and remained unaffected by the band application of the herbicides.

The height of the companion crops reached the level of the winter wheat in the middle of May. Corn flowers were extremely dominant, and the generally harmless chickweed also grew strongly in the wheat. A total of 14 plant species emerged in the biodiverse variant, 6 of which had been sown in the autumn. Annual meadow grass was the only plant species found in the conventional variant. A very positive overall conclusion for biodiversity was drawn in a bachelor's thesis on vegetation ecology (Prof. Kathrin Kiehl, Osnabrück University of Applied Sciences).

A knife roller was inserted in the front attachment to protect the harvest in BBCH 37 on 16th May. The SCHMOTZER knife roller was developed for the Renuwi research project (funded by the Federal Environmental Foundation) and borrowed for this application. At a speed of 10 km/h, the double knife roller provided excellent shredding of the wild plants and only caused minor damage to the wheat.

With good soil coverage, the dead plant material ensured that the soil moisture was retained in the following dry period.

The wheat crop developed extremely well during flowering and the grain filling phase and the companion crops were barely perceptible. There was a long rainy period from the end of June to the beginning of August, with the result that the regulated herbs re-established themselves.

Despite the fact that some of the companion crops (corn poppy, red campion, corn flower) were flowering again, combine harvesting was possible on 20th August without any problems with a stubble height of approx. 10 cm.

Whereas an excellent yield of 94 dt/ha was obtained in variant A (conventional), the yield in variant C (CRF-reduced) was 25 % lower at 70 dt/ha. With 82 dt/ha, the grain yield of variant D (CRF-optimised) was at a similar level to the yield of variant B (modern) with 86 dt/ha.

Since the trial was set up purely as a block design without repetition, the results are not statistically corroborated. However, the significant loss of yield in variant C is a good indicator of what is likely to occur if provision is made for biodiversity.

SCHMOTZER knife roller in use

Weed management in oats – clear insights

On 19th March 2022, oats of the Lion variety were sown in the Controlled Row Farming trial at Gut Wambergen. Interesting insights into the various control strategies against weeds were obtained after the harvest.

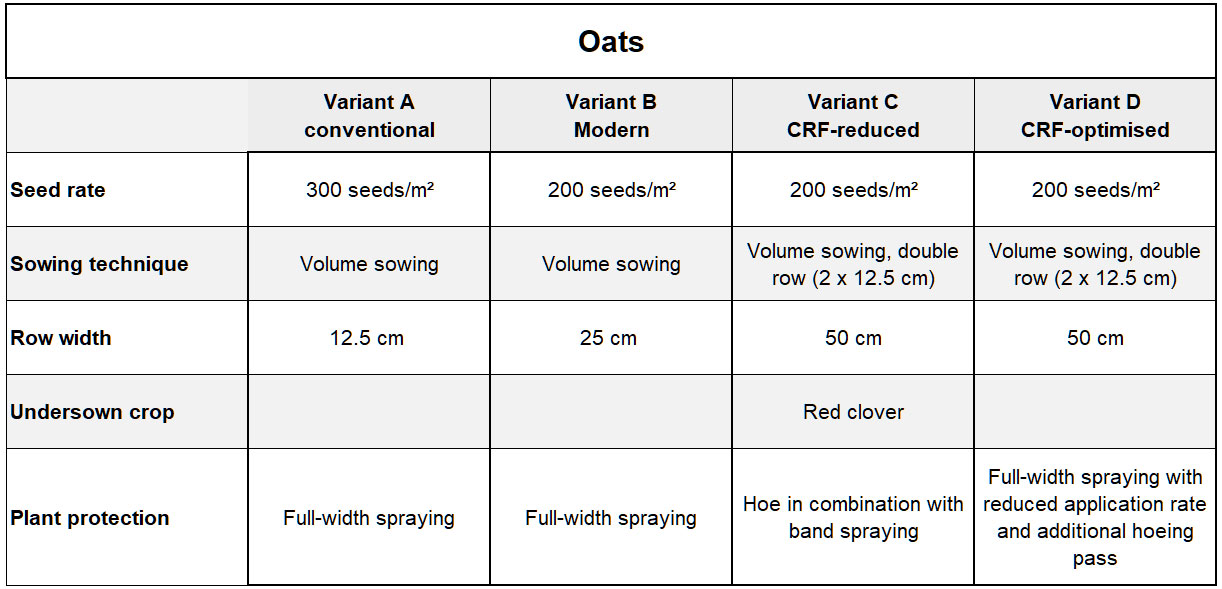

The cultivation system follows the same principle of the last few years:

- Standard (A) with 12.5 cm row spacing and 300 seeds/sq m - with the usual full-width spraying

- Modern (B) with 25 cm row spacing and 200 seeds/sq m - with the usual full-width spraying

- CRF-reduced (C) with double row at 50 cm and 2 x 12.5 cm row spacing and 200 seeds/sq m - with hoe, undersown crop and band spraying

- CRF-optimised (D) with double row at 50 cm and 2 x 12.5 cm row spacing and 200 seeds/sq m - with the usual full-width spraying

In accordance with the strategy which is usual in the region, 50 g/ha Pointer Plus and 1 l/ha U46M were applied to all variants on 28th April for weed control. The application was full-width in variants A, B and D. The identical spray rate per hectare was applied as a band spray in variant C. With a band width of 20 cm, we achieved herbicide savings of 60 %.

Surface plant protection in oats in the Standard (A) variant on 28th April 2022

UX 5200 Super with 27 metre Super-L boom

On the same date, hoeing was carried out in a single pass, band application of the herbicide on the double row was provided and 18 kg/ha of red clover was sown in the 30 cm intermediate area.

In addition, an application of fungicide and growth regulator was provided on 15th May. This application was not varied in the trial.

Field emergence was delayed and the competitive vigour of the oats was strong owing to the dry conditions after hoeing. The promotion of biodiversity was not very successful in the main growth phase of this summer cereal.

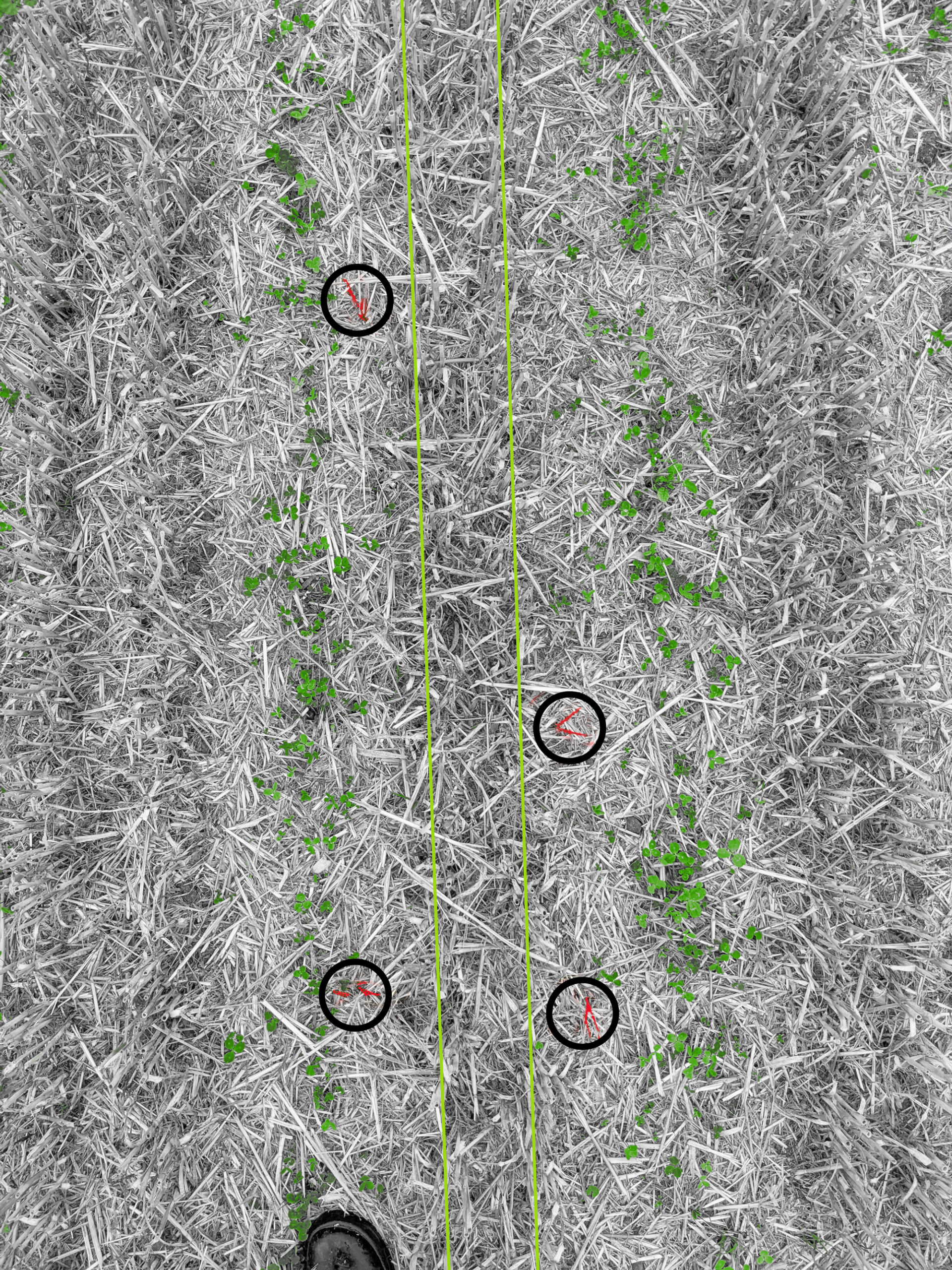

The appearance of the trial variants after the harvest is all the more interesting. The oats were threshed on 25th July with yields of around 70 dt/ha.

The increased emergence of annual meadow grass (Poa annua) in some variants after the harvest is conspicuous. Annual meadow grass is a problem weed on this site and is not completely controlled by the herbicide used.

Extremely low weed persistence is apparent in the customary “Standard“ variant. As is known, oats suppress weeds very well at close row spacings.

The population of annual meadow grass is worth controlling in variant B with a 25 cm row spacing. With the same herbicide application, it can be assumed that the greater and longer light incidence promoted the growth of the meadow grass. Shallow soil tillage or a total herbicide after the harvest would be appropriate, in order to prevent the spread of the meadow grass.

The red clover established itself surprisingly well in variant C. It can be assumed that it had sufficiently germinated and initially developed only very slowly under the oats. Heavy rainfall of 38 mm just before the harvest on 21st July then undoubtedly helped the increasing light to be used in the ripening crop.

The advantages of a combined control strategy are apparent in variant C with double row at 50 cm and 12,5 cm row spacing. Only red clover and no annual meadow grass can be found in the working range of the hoeing machine. The meadow grass undoubtedly emerged at the same time as the oats and would have spread as in variant B or D. The use of the hoeing machine on 28th April was ideal,as it removed the annual meadow grass. The red clover established itself and the close row spacing in the double row in combination with band application of the herbicide suppressed the meadow grass very well. Annual meadow grass can occasionally be seen in the transitional area of the hoeing machine and band sprayer. The meadow grass was obviously promoted by the intense light incidence at the edge of the double row. The hoe share could not reach several plants close to the row.

The annual meadow grass remains below the control threshold after the harvest in variant C. Weed control was extremely successful with a 60% reduction in herbicide use.

Oat stubble with 50 cm double row after hoeing machine and undersown red clover (C) on 28th August 2022

Green lines: Oat stubble in the double row

Red plants: Annual meadow grass

The same problems as in variant B with 25cm row spacing become apparent in the double row without use of the hoeing machine. The meadow grass was able to establish itself and should be immediately removed for the purposes of field hygiene.

The weather conditions indicate relatively well distributed precipitation. The good field capacity of the soil always provided the oats with sufficient moisture and produced good yields of 70 dt/ha.

Crop season plan 2022

Three summer crops will be grown in the cultivation year 2022: field beans, oats and grain maize. The plots were restructured, and a uniform basis was created with a plough furrow.

Fig.: Location of the trials in the “Meyer zu Wambergen” field

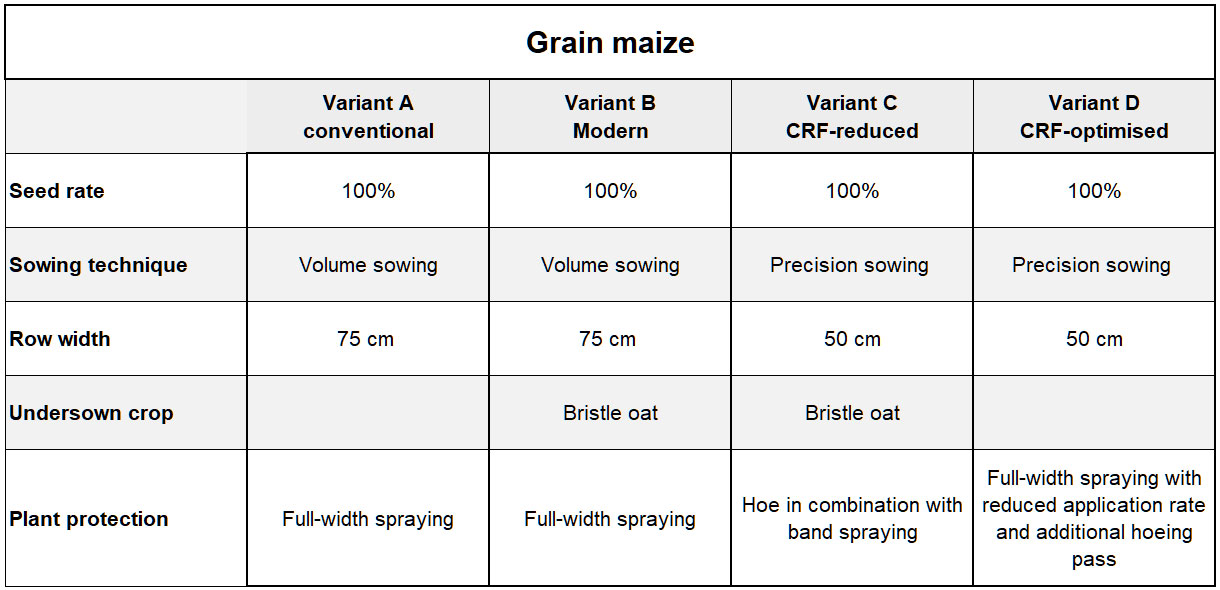

Field beans and oats will be sown with a Centaya drill combination with a 12.5 cm row width in the standard variant. The row width will be doubled to 25 cm in the modern variant. The sowing rate of the oats and field beans will be reduced by 1/3, so that the seed gaps in the row are not too small. The seed rate will not be varied for maize since the individual plants cannot tiller and compensate for this. The reduced seed rates will also be used in the two CRF variants. The distribution in the field is the only difference, because two rows are closed in the CRF system and a double row is then sown with 12.5 cm. We have reduced the seed rate of winter cereals by 50% in the modern variant and the CRF variants in recent years - with good results (see winter barley 2021). The CRF variants will also be sown as double rows with the drill combination for oats. This would also be possible with the field beans. We thought it would be more interesting to sow 50 cm rows with a precision air seeder. We will see how the crops develop with the same seed rate compared to the modern variant. We decided to use red clover as a companion crop in the oats in the reduced CRF variant. The red clover will be sown as early as possible in combination with band spraying. It is vigorous and should establish itself intensively. Mechanical reduction with a row-specific roller will be possible if it endangers the maturation of the oats.

The pre-emergence spraying in the field beans will be provided by band application. Persian clover will be sown in the first hoeing pass. This is a low-growing crop and should not disturb the field beans too much until harvest. Reduced crop protection treatment will be applied over the entire area in the optimised CRF variant, in order to give the field beans a head start. The hoe will potentially be applied twice, in order to suppress weed competition.

The Precea precision air seeder will be used to sow the grain maize at 75 cm in both the standard variant and the modern variant. The seed will be sown at 50 cm in the two CRF variants. The herbicide will be applied in the modern variant with a reduced amount of soil herbicide, in order to permit an undersown crop. As hardy ryegrass could become problematic in the crop rotation, bristle oat was selected as a frost-intolerant undersown crop. The undersown crop increases biodiversity and improves accessibility during the harvest. The mulch offers good protection against erosion over the winter. The full herbicide mixture in the CRF-reduced variant is used in the same way as in the conventional variant but will be applied by band spraying. It will be interesting to see whether the bristle oat undersown crop develops better in the herbicide-free intermediate area than in the modern variant. A full-area, somewhat weaker herbicide mixture will be used in the CRF-optimised variant, in order to give the maize a head start. Depending on the weather conditions, 1-2 additional passes will be made with the hoe.

DLG-Agrifuture Concept Winner 2022

The “DLG-Agrifuture Concepts” innovation prize for pioneering achievements and visions for the future in agricultural technology was awarded for the first time during Agritechnica. The “CRF - Controlled Row Farming” farming concept from Amazone, Agravis Raiffeisen and Schmotzer Hacktechnik was chosen as one of the winners from a shortlist of ten nominated innovations. The jury of independent international experts appointed by the DLG (German Agricultural Society) thereby recognised the new arable farming system for promoting biodiversity through cultivation with uniform row widths.

The DLG is supporting pioneering concepts for the future of global crop production with this new award. The award ceremony took place on 15th February 2022 as part of an online event.

Link to the DLG press release: https://www.dlg.org/de/landwirtschaft/presse/aktuell#!/news/dlg-agrifuture-concept-winner-2022-die-preistraeger-fuer-den-neuen-zukunftspreis-agrartechnik

Link to the Agritechnica website: https://www.agritechnica.com/en/agrifuture-concept-winner/winners-2022

Field trials at Wambergen

The Controlled Row Farming method of cultivation is being tested on a trial area in the immediate vicinity of the AMAZONEN-WERKE factory in Hasbergen-Gaste.

The trials are for demonstration purposes and, following initial tests in 2020/2021, are now being set up in a structure which can be sustained in the long term. The trial design is adapted to the 27-metre tramline system of the partner company which manages the land in Wambergen.

Three crops are grown each year on the 3 ha trial area in a 10 ha field, in order to make the trial attractive to visitors. Each crop has four variants with a width of 12 metres. This makes it possible to repeat plant appraisals over a length of approx. 150 metres and to record crop yields by means of core threshing. The 12-metre wide plots allow working widths of three and six metres for sowing and cultivation.

The four trial variants Standard (A), Modern (B), CRF-reduced (C) and CRF-optimised (D) are laid out in the form of simple strips. Randomisation is not possible at this location in the arrangement with series technology.

Standard: This trial variant demonstrates the conventional, classical cultivation customary in the region. It provides a realistic opportunity to measure or compare the different trial variants against this conventional variant.

Modern: The “modern variant” is cultivated with the usual land management and extended by current and innovative plant cultivation measures. These could be alternative row widths and seed rates, undersown crops or alternative plant protection strategies.

CRF-reduced: The aim of the CRF-reduced variant is to put the companion plants in the foreground and to devote particular attention to the promotion of biodiversity with a reduced use of inputs. The row spacing of 50 cm is provided in single or double rows, depending on the crop. The companion plants in the intermediate area should develop early and intensively. Depending on the crop and the seasonal weather conditions, the companion plants can be mechanically reduced in the rows, in order not to endanger the maturity and threshability of the main crop.

CRF-optimised: The CRF-optimised variant pursues the goal of keeping yields stable with optimised input costs. The inputs can be applied exclusively in the row by sowing with a row spacing of 50 cm, which is identical to the CRF-reduced variant.

Sowing, mechanical cultivation measures and band spraying are carried out with 6-metre working widths using RTK-guided tractors. Sowing with a working width of 3 metres and hoeing with a working width of 6 metres are possible as we do not have to hoe “to the last centimetre” in the row in the conventional system.

A standard 27-metre crop protection sprayer is used on the 3-metre grass strip outside the actual trial site for full-area plant protection. The machine can run different applications on a plot-by-plot basis by switching off the part-width sections. Row-specific nozzle technology or drag hose systems for liquid fertilisation can also be used in the 50cm CRF system.

A complete plot can also be fertilised with granulated material via the lateral grass strips with a twin disc fertiliser spreader. The new Border-TS border spreading system provides excellent lateral distribution within the 27 metres. The use of a pneumatic spreader, which is often used in field trials, is not necessary.

The grass strips have the advantage of being easy to drive over all year round and are also easy to access during field inspections.

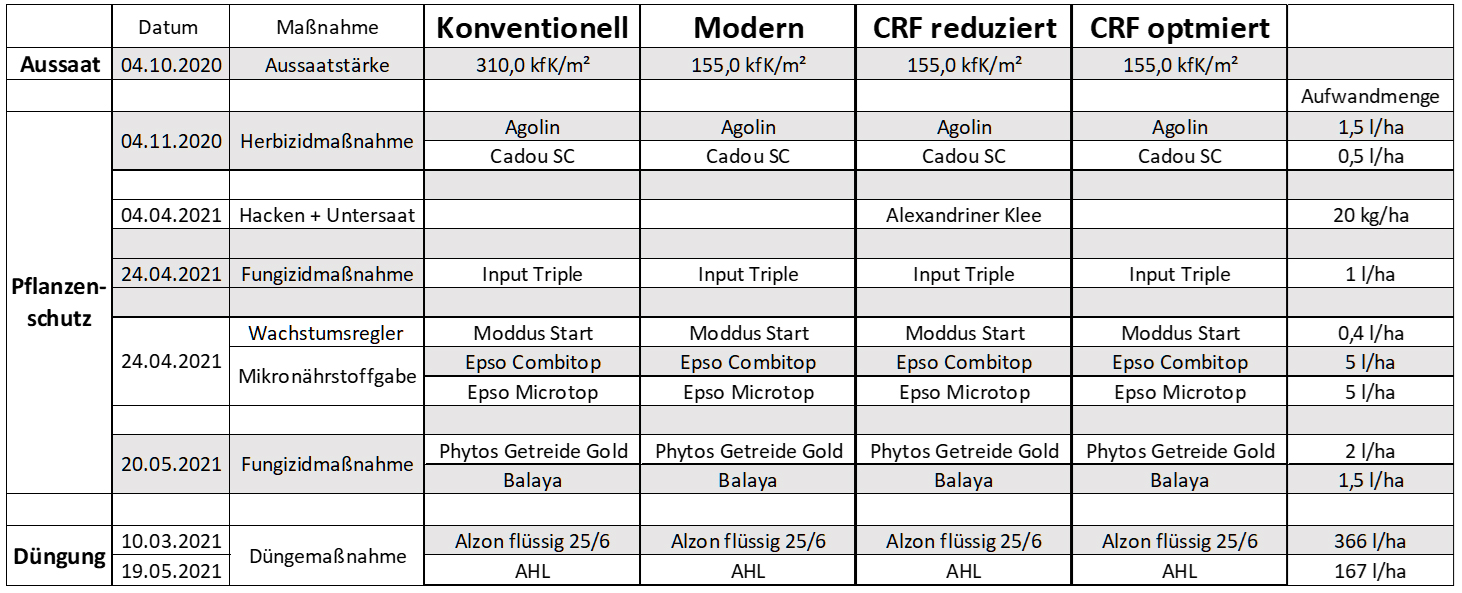

Cultivation year 2020/2021 – Winter barley

All winter barley trial variants produced the same yields in the 2021 harvest! There are also no differences between the double row with a 50 cm row width with undersowing and the other variants. Winter barley of the variety "KWS Wallace" was sown on 04.10.2020. The sowing rate in the conventional variant was 310 germinable grains / sq m, with a row width of 12.5 cm. The theoretical seed gap within the groove was 2.58 cm. Only the seed rate was halved for the same row width in the modern variant. 155 seeds/sq m result in a theoretical seed gap within the groove of 5.16 cm. The two CRF variants were arranged identically: always two rows with 12.5 cm spacing and then two rows closed, in order to allow space for the companion crop with 50 cm spacing of the double row. The theoretical seed gap within the groove is 2.58 cm and is identical to the conventional variant. Herbicide was applied to all variants over the full area on 04.11. for weed control. It was impossible to use a hoe because of regular rainfall in October. The alternative of band spraying in the autumn with an initial hoeing pass in early spring seemed very risky to us owing to a very high weed pressure. Fortunately, we have a level of flexibility in the CRF project and can solve particular challenges with full-area applications. We will try planting the undersown crop while sowing the main crop or shortly afterwards in the future.

Further crop management with fertilisation and plant protection was the same for all variants. Details can be found in the following graphic.

Hoeing in combination with the sowing of Egyptian clover was carried out in the “CRF reduced” variant on 04.04.2021. The clover developed relatively slowly at first because of competition with the barley and the extremely cold spring. Even though it looked relatively good before harvest, the effect is relatively small in terms of promoting biodiversity. We plan to promote companion plants more aggressively next year.

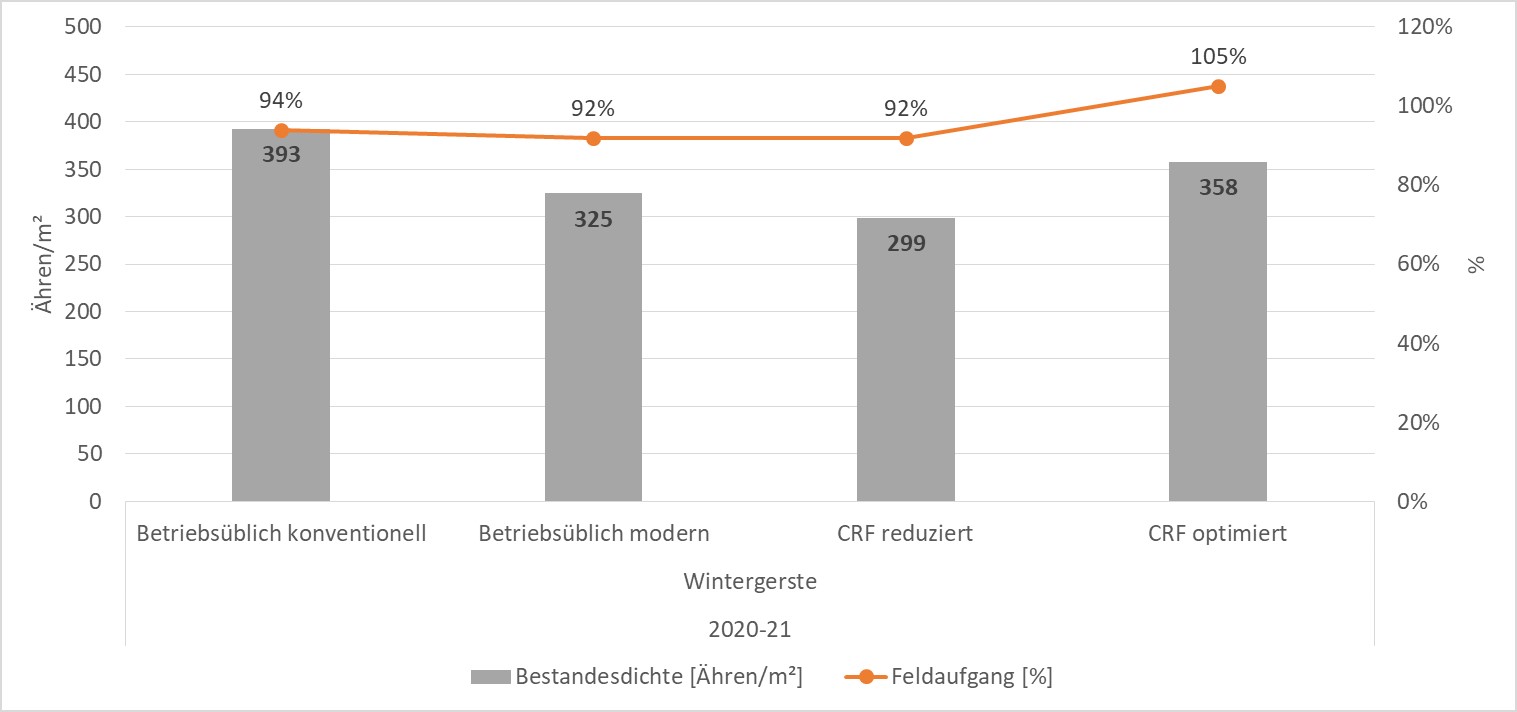

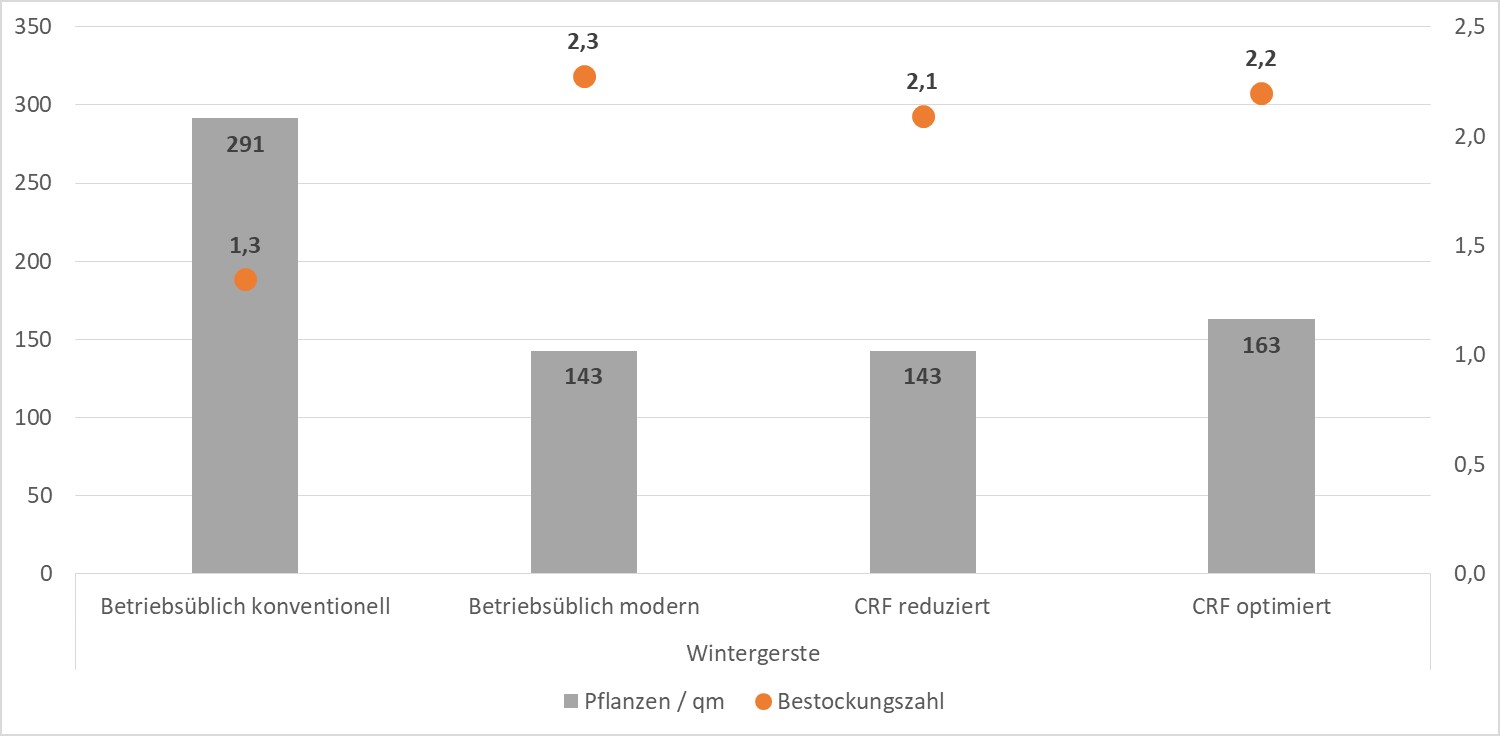

The following conclusions can be drawn from the key figures: Field emergence was between 92 % and 105 % (*), i.e. at a very high and comparable level.

* Very good germination capacity and inaccuracies in metering or longitudinal and transverse distribution can lead to measured values > 100%. Plant density shows the difference more clearly. Almost 400 ears / sq m are formed at high seed rates. The tillering rate is 1.3 (each plant forms 1.3 ears on average). The plant density n is up to 25% lower at the low seed rates of 155 gr/sq m. However, the winter barley formed more than two ears per plant on average.

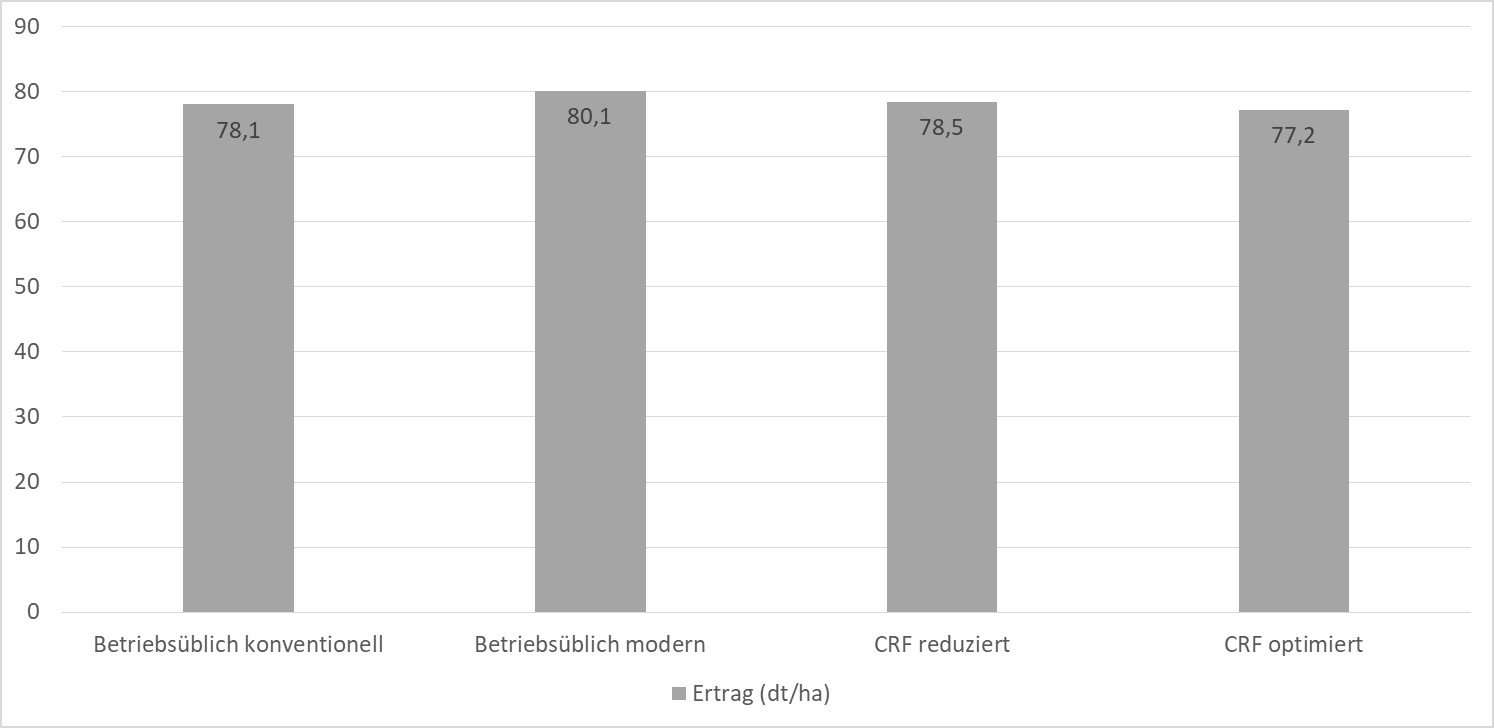

The winter barley was harvested on 24 July. The complete block of each variant was threshed and weighed. The yield of 78 dt/ha is average for the site and the region. The differences between the variants are so small that we can say that all variants produce uniform yields.

The lower number of ears was obviously compensated for by stronger grain formation.

Economic consideration of the Controlled Row Farming system

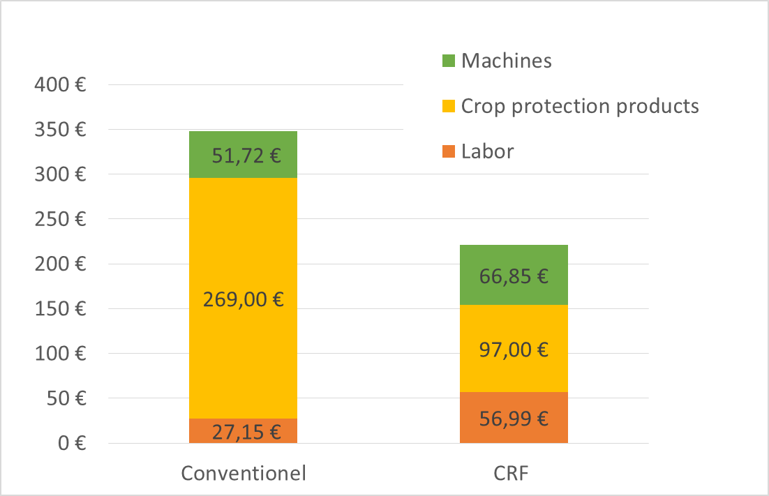

Apart from the practical implementation of the Controlled Row Farming method with regard to the plant cultivation and ecological effects, the question of economic viability also arises. How does the increased financial expenditure for technology, labour and time required in this alternative arable farming system compare to the savings, especially for fertilisers and plant protection agents?

We see the medium-sized arable farms of Western Europe as the target group for the method. A fictitious 350-hectare arable farm in the Börd landscape south of Hanover serves as the basis for the following considerations. We calculated alternative scenarios together with a student work group from the Osnabrück University of Applied Sciences.

Mechanisation for application of the CRF system

The initial situation is assumed to be the usual regional mechanisation in a 27-metre tramline system: A plough, cultivator and compact disc harrow can be used with a 200 hp tractor. A 3-metre sowing combination with active tillage, a precision air seeder, a mounted fertiliser spreader and a trailed field sprayer are common equipment on a farm with a tradition of good revenues from sugar beet.

When converting to the CRF system, the focus is on reorienting the entire farm to 6-metre sowing and hoeing technology. Various implements can be supplied via the FTender 1600 front tank: Cereal seed coulter with 12 double rows and TwinTec coulters with a 15 cm spacing. The 12-row precision air seeder can be used to apply under-root fertilisation via the front tank, and the 12-row hoeing technology can be used to apply undersown crops. A strip-till cultivator with variable, row-specific 25 or 50 cm spacing, which could be used to deposit fertiliser from the Ftender, under the surface, has not yet been considered but is foreseen in the system.

Precise band spraying integrated in the hoeing technology is also at the heart of the system. The FT-P 1502 front tank and the row spraying device are therefore part of the mandatory equipment. The UX 4200 Special trailed sprayer with 27 m is replaced by an UF 1302 mounted sprayer with 18 m, in order to continue to make the most of the front tank. In combination with the FT-P 1502, the tank is large enough to achieve acceptable acreage output.

Other tramline systems and mechanisation are also conceivable. For example, band spraying with a conventional trailed sprayer (see AmaSelect row) is also possible. This has a significantly higher acreage output but does not provide the precision of an integrated band spraying system.

Cooperation with neighbouring farms in the inter-farm use of fertiliser and crop protection technology can also be appropriate if the bulk of the applications are placed row-specifically and the utilisation of the farmer’s own standard machines is thereby unduly reduced.

Economic benefits of the effects of the CRF system

The core of the CRF system is the row-oriented placement of as many inputs as possible. Herbicide savings are very easy to examine. If the band width is 10 cm for crops in single rows (maize, sugar beet, rape) and 20 cm for double rows in cereals, a 50 cm row width results in reductions of 80% and 60% respectively. Savings of fungicides and insecticides are also conceivable in row-specific applications with e.g. droplegs. They were not considered in the initial calculations, as sufficient knowledge about plant cultivation is not yet available.

The increase in efficiency arising from placed fertilisation has been known about for years, especially for maize. It is also increasingly being used for the seedling development of cereals (see SingleShoot method). Further fertilisation measures will be applied row-specifically in the CRF system depending on the mode of action of the fertiliser type. Both the hoeing technology and the conventional sprayer open up various possibilities for placing solid and liquid fertilisers next to, on top of or under the row. We assumed that only the third application in cereals is applied across the full working width for this calculation, which means that only 26% of all fertilisation measures are applied across the full working width. We assumed a moderate increase in efficiency of the fertilisation measures of 10% at constant yields in the calculation.

Taken together, the above reduction potentials provide a cost reduction of 43 % or 64 € / ha for plant protection and 10 % or 10 € / ha for fertilisation.

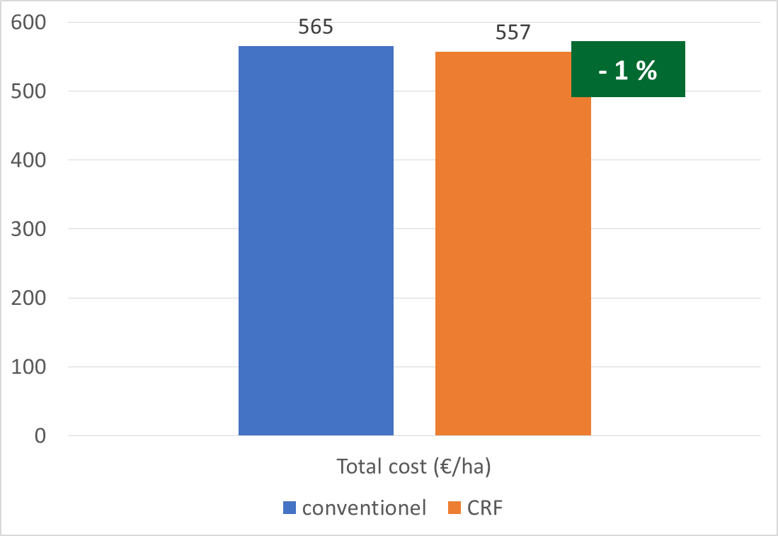

The use of implements with smaller working widths and tanks for band spraying and fertiliser placement results in significantly lower outputs per hour, which have a negative economic impact. This results in an increase in machinery and labour costs of 63% or 14,945 € / year in the calculation.

On balance , however, it becomes clear that the absolute costs per hectare for the machinery increase less than the reduction in the costs of the plant protection agents. This is despite the fact that we set a very high hourly rate of 60 €/hour in the calculations for all work involved. Shifting the work from the farm manager to a part-time driver can bring additional reductions.

- The increase in machinery costs due to the use of hoe, front tank and band sprayer is 15 € / ha.

- The additional working time results in costs of just under 30 € / ha.

- This is mainly offset by the reduction in costs arising from herbicides - these total over 170 € / ha.

The balance varies greatly depending on the crops. The intensive use of herbicides in sugar beet brings clear cost advantages. There are slight advantages in maize and rape and the effects cancel each other out in cereals.

The costs of the CRF system are 1 % below the usual land management if the complete crop rotation of the 350 ha farm is considered.

The challenge of working time

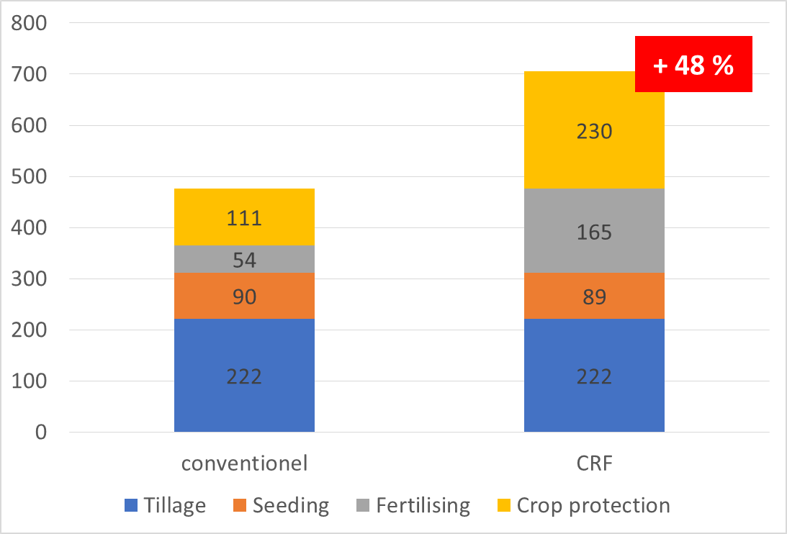

The change in mechanisation results in completely different outputs per hectare. The Amazone output calculator shows an output of 12.4 ha / hour for the initial situation with the UX 4200 Special, 27 metres, with a total annual output of 1370 ha. The conversion to herbicide band spraying with a hoe and the FT-P results in a required annual output for the combination of about 670 ha. With an output of 4.9 ha/hour, one of the main challenges of the CRF system becomes apparent. The usual full-width application is reduced to about 700 ha / year with an hourly output of the 18m mounted sprayer of 7.7 ha. The difference between the usual full-width spraying and the use of hoeing technology becomes more striking when the working time required for 120 ha is considered. The 27-metre sprayer requires approx. 10 hours, the 6-metre hoeing technology 24 hours.

Adding together all operations over the complete crop rotation, including all downtimes such as transport and filling, shows an increase in the working time requirement of 48 %. This is a challenge from the point of view of regional difficulties in finding labour for agriculture and increasing labour costs. Sufficient labour is available from a global perspective, but it has not yet been possible to resolve this imbalance on a political level.

The increasing automation of work processes in connected implements (e.g. steering of the hoe, control of work quality with Argus Twin) leads to higher outputs per hour due to a reduction in the driver’s workload and higher forward speeds. As can be seen from the example of precision seeding (EDX, Precea), much has been done in recent years to maintain the quality of work, even at high speeds.

In the medium term, Controlled Row Farming would be ideally suited for a complete workforce of autonomous field robots, thereby solving the challenge posed by increased working time requirements. In this case, the working widths can become smaller again and the speeds decrease if the available working days permit this. This could potentially be of benefit to precision and work quality and, last but not least, lead to a reduction in diesel consumption per hectare.

Introduction of the CRF system in September 2020

Introduction of the CRF system in September 2020

Introduction of the CRF system in September 2020

Contact

The utilisation and testing of a wide variety of digital methods from field surveying and the use of machinery to the assessment of the crops and evaluation of the yields is an integral part of the CRF project.

AMAZONE | |||||

DSV |