In order to tailor the horizontal boom ride to the growing demands, e.g. wider widths and higher forward speeds, AMAZONE offers SwingStop active boom tip movement prevention as an option for the ContourControl boom guidance system. By external influences, such as ground undulations, driving round bends, acceleration and deceleration and increasing operating speeds, the boom is under extraordinary strain in the horizontal plane. This may result in the boom ends swinging back and forth and thus negatively affecting the lateral distribution at the outer ends of the booms.

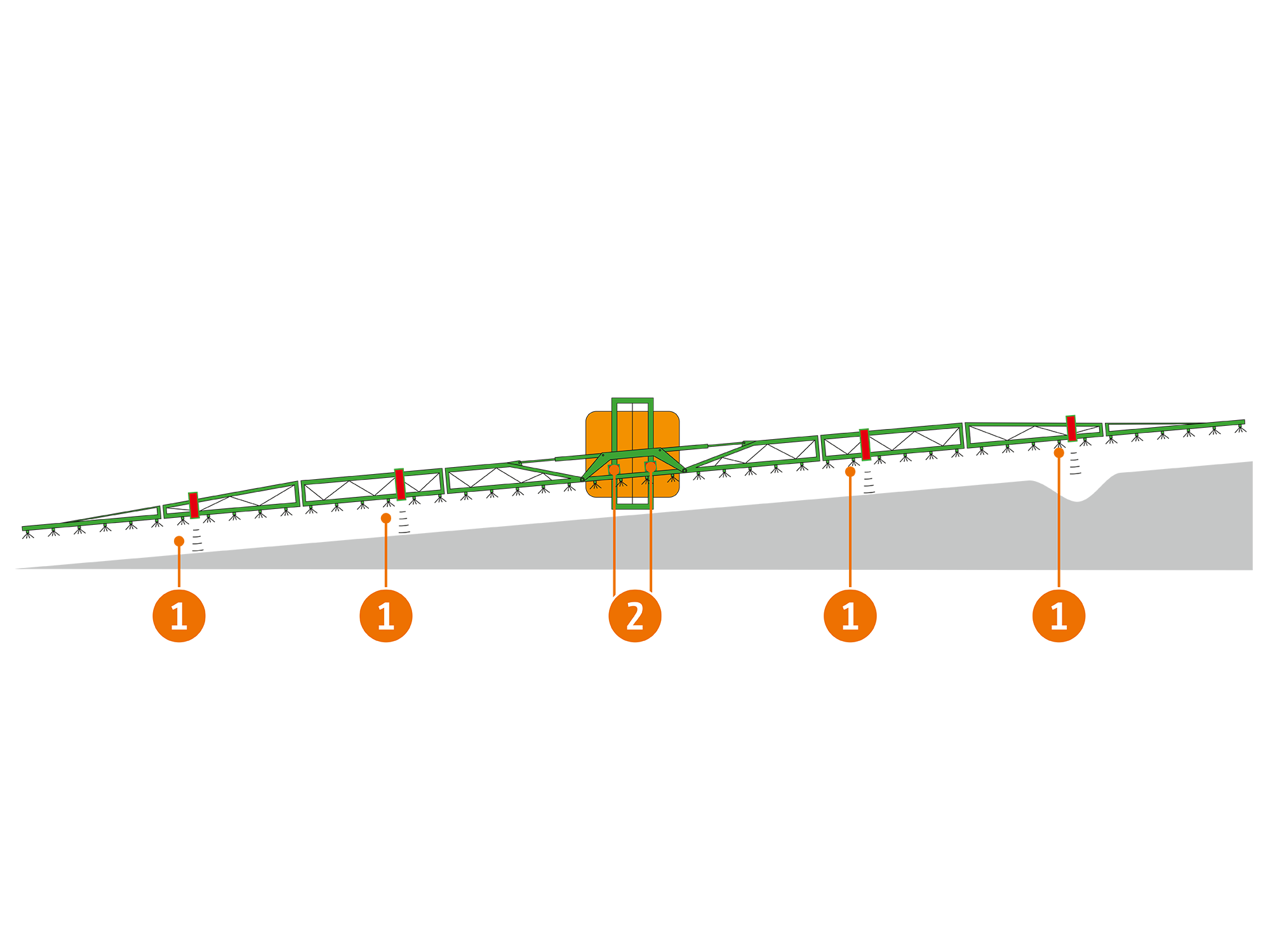

Since horizontal movement occurs more at the boom ends, this effect is amplified by large boom widths. To reduce this horizontal tip swing effect, SwingStop measures, via acceleration sensors, the resulting acceleration at the boom ends. The two actively operating hydraulic rams in the boom suspension compensate live for these swing movements and in this way provide a very smooth horizontal boom ride.

The benefits of SwingStop:

- Optimum longitudinal distribution

- Reduction of the horizontal boom movement for a very smooth boom ride

- A system which operates very quickly and precisely, even at high working speeds

- Highest performance and outstanding precision

“A total of six ultrasound sensors take care of the height guidance of the parallelogram frame, the adjustment of the slope compensation and the control of the boom angling (positive and negative). It is fantastic in hilly terrain, particularly when it comes to being able to spray more quickly and with a shorter distance above the target surface.”

(“profi” – “Practice test Amazone UX 4201 Super” 02/2020)

And now when it comes to the keyword “fast”, then “SwingStop” also comes into play: This is an active, hydraulic control system with acceleration sensors in the ends of the boom which counteracts horizontal swinging – and does so before any movement visible to the eye occurs.

(“profi” – “Practice test Amazone UX 4201 Super” 02/2020)