Weed Detector for spot application in grassland

Efficient rumex control in grassland using AI based plant detection during forage harvesting

The control of rumex weeds in grassland is an essential measure to achieve the highest forage quality. As an alternative to indirect or mechanical measures, chemical treatment has no longer been permitted as a full area spraying method in some regions since 2022. Targeted, selective treatment can be carried out by brushing or spot spraying. There are currently some specialised spot spraying devices that can detect rumex weeds during a pass and apply it directly. These specialised devices are expensive and, in contrast to conventional crop protection sprayers, are significantly limited in their range of applications. In addition, only a small working width can be covered, so the labour requirement is significantly increased, as the whole area must also be driven over.

Targeted recognition and agronomic evaluation

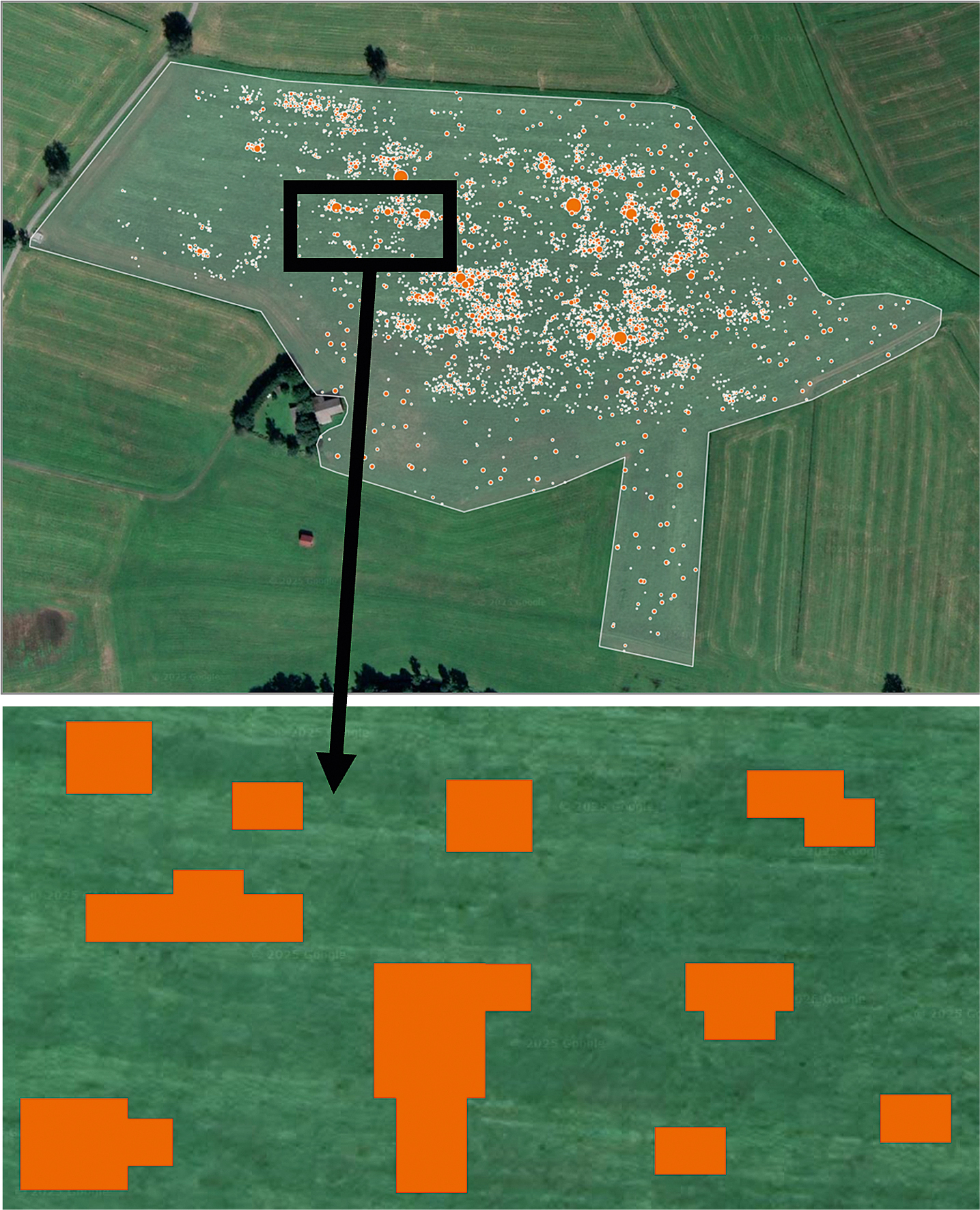

A new approach to rumex control using selected area spraying solves the challenges of previous methods. With the Weed Detector, CLAAS has developed a system for its mowers that uses a camera to detect rumex plants during mowing. A camera system is mounted on the headstock on the front mower, which reliably captures the entire working width. AI-based software analyses the images and creates an infestation map. The data from several cuts can be taken into account here.

In addition, the farmer is able to carry out an agronomic assessment with potentially treatable zones before transferring them to the crop protection sprayer. In accordance with good professional practice, treatment is carried out at a later stage than mowing so that the rumex plants can form leaf mass.

The leaf mass represents the required application area for the product. An agronomic safety buffer of 50 cm around the detection points, for example, is defined in the CLAAS connect Farm Management based on knowledge of the site and the field history. The selected area spraying step is not time-critical, because it is necessary to wait a few days after mowing before application, until the rumex has sufficiently resprouted.

The map with the agronomic target zones is transferred to the cloud-based data platform AmaConnect. The application maps are created there depending on the level of technology on the crop protection sprayer. This map, with the agronomic target zones, enables a precise advance calculation of the necessary amount of spray agent needed for each field.

Precise spot application with AMAZONE AmaXact

The savings potential of spot spraying depends not only on the level of infestation but also to a large extent on the size of the part-width sections on the crop protection sprayer. The smaller the part-width sections, the greater the savings. The application technology with individual nozzle control - and therefore 50 cm part-width sections - from AMAZONE is therefore particularly suitable for this application. In addition to the new AmaXact nozzle body, rumex control also works with the tried-and-tested AmaSelect nozzle body. This enables farmers to utilise existing machinery and participate in innovation.

Thanks to its robust interpretation for frequent switching cycles, the new AmaXact nozzle body with pulse width frequency modulation (PWFM) is ideal for spot spraying. Based on the short actuation times required for spot spraying, the spot size can be reduced even further using the AmaXact system. The savings in pesticides are greater and the amount of spray agent required is correspondingly smaller. This makes sustainable plant protection possible.

Data transmission via cloud-to-cloud communication

To make data management clear and user-friendly, the spot map can be transferred completely wirelessly. The mower sends the data to CLAAS connect Farm Management on the mobile network. This forwards the map to AMAZONE's AmaConnect data platform via cloud-to-cloud communication. Depending on the existing application system, AmaConnect automatically optimises the application maps received. This ensures that rumex plants are treated reliably in practice. The user receives the total size of the spot areas so that the amount of spray agent can be made up appropriately.

The spot map is sent to the AmaTron 4 before use, via the AmaTron Share App or, in future, directly to the cloud via AmaConnect. Now a targeted spot application with the crop protection sprayer can be carried out at the optimum agronomical time.

Special advantages of the system with AmaXact and the Weed Detector

The Weed Detector system saves significant amounts of plant protection products in grassland without having to invest in special application technology. Performance can be significantly increased compared to special SpotSpray devices due to the wider boom widths.

Compared to flying over the field with a drone to detect the rumex plants, the system offers the advantage that mapping takes place during mowing, i.e. without an additional steps. The technology can also be used under all conditions: In practice, flying a drone is often impossible under windy conditions, on hilly terrain or with obstacles, such as power lines.

The division of tasks makes the system easy to use for every practitioner: The camera on the CLAAS DISCO MOVE front mower detects the rumex and makes it possible to prepare the application. The farmer, machinery pool or contractor can run the job by transferring it to the AMAZONE AmaConnect data platform. The inter-company sharing of expertise facilitates ideal synergies and, above all, enormous cost advantages in the rumex control process.

- Highly accurate rumex detection without an additional pass

- Simple, practical data processing

- High savings potential combined with high performance level

- Spot application without expensive specialist machinery

- Measurable treatment success as a result of multi-year data recording

Gallery