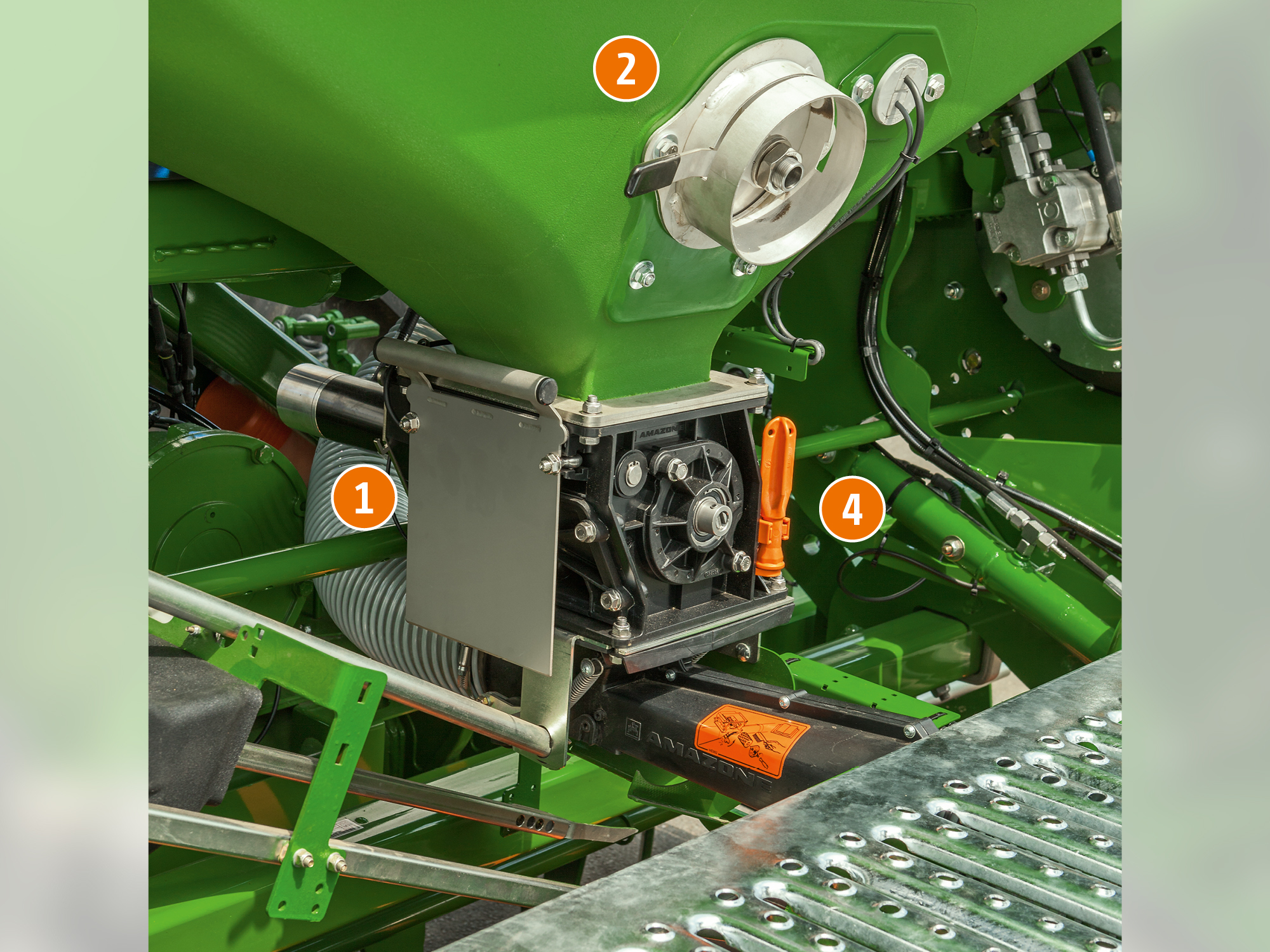

Convenient calibration via the SmartCenter on the left hand side of the drill thanks to the calibration button or, as an option, using the TwinTerminal 3.0. For this, the tray for the calibration is placed directly underneath the metering unit. Subsequently the calibration tray can be removed comfortably via the SmartCenter. Thanks to the intelligent integration of this function, the calibration tray can be removed only when the metering flap has been closed via the remote linkage.

During the calibration procedure, the seed is delivered safely and cleanly into the calibration tray. Also decanting into the supplied folding bucket is done quickly, easily and comfortably. After calibration, the calibration tray is simply, with its opening facing downwards, stored in the park position.

The digital weighing scales, provided as standard, enable the exact weighing of the calibrated seed. Additional storage space in the SmartCenter provides sufficient room for the folding bucket and the digital scales.

- “All the important settings on the seed drill are carried out from the left hand side. “Calibration is quickly done.”

(“agrarheute” test report with the Centaya 3000 Super · 06/2018)