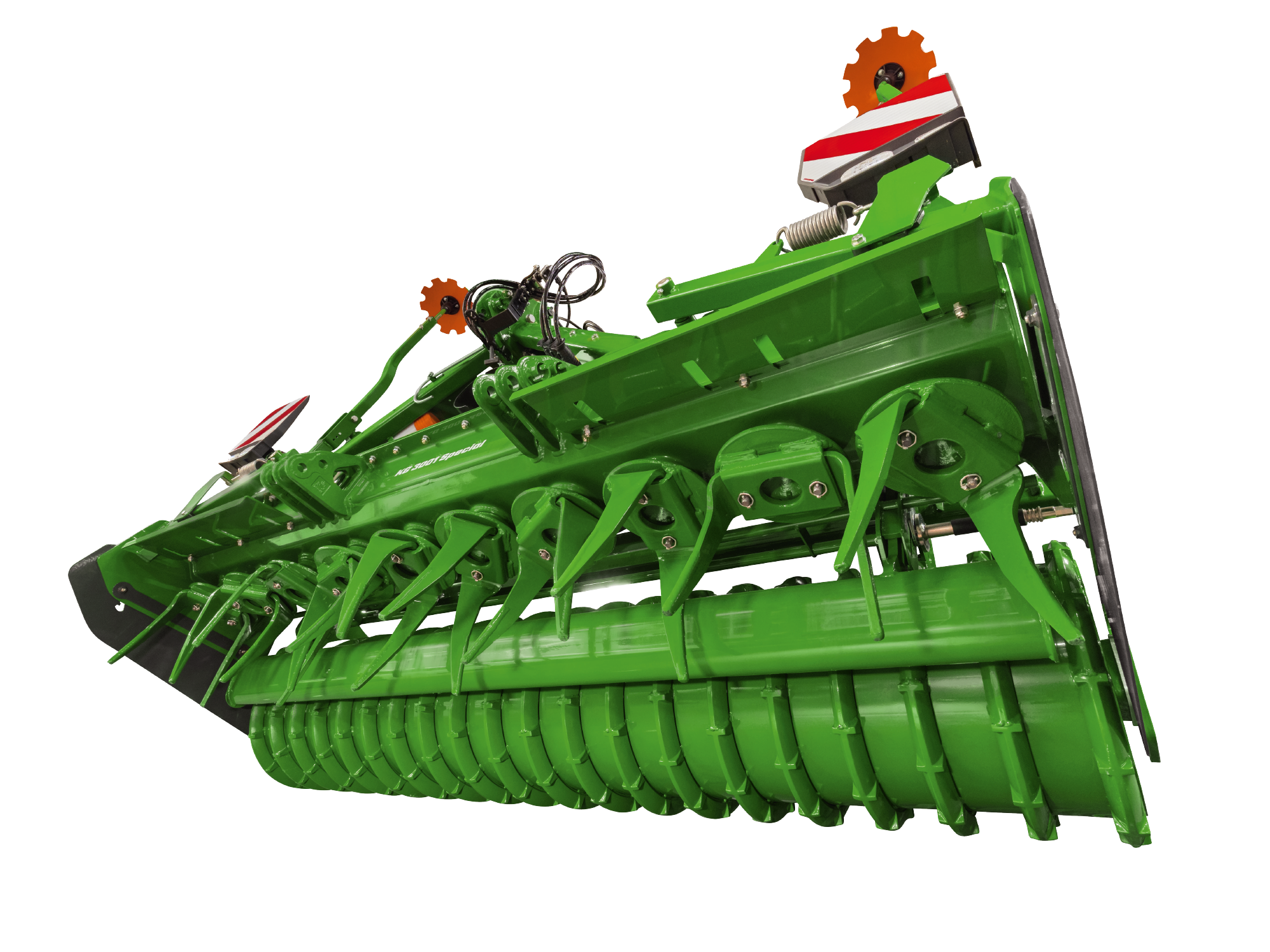

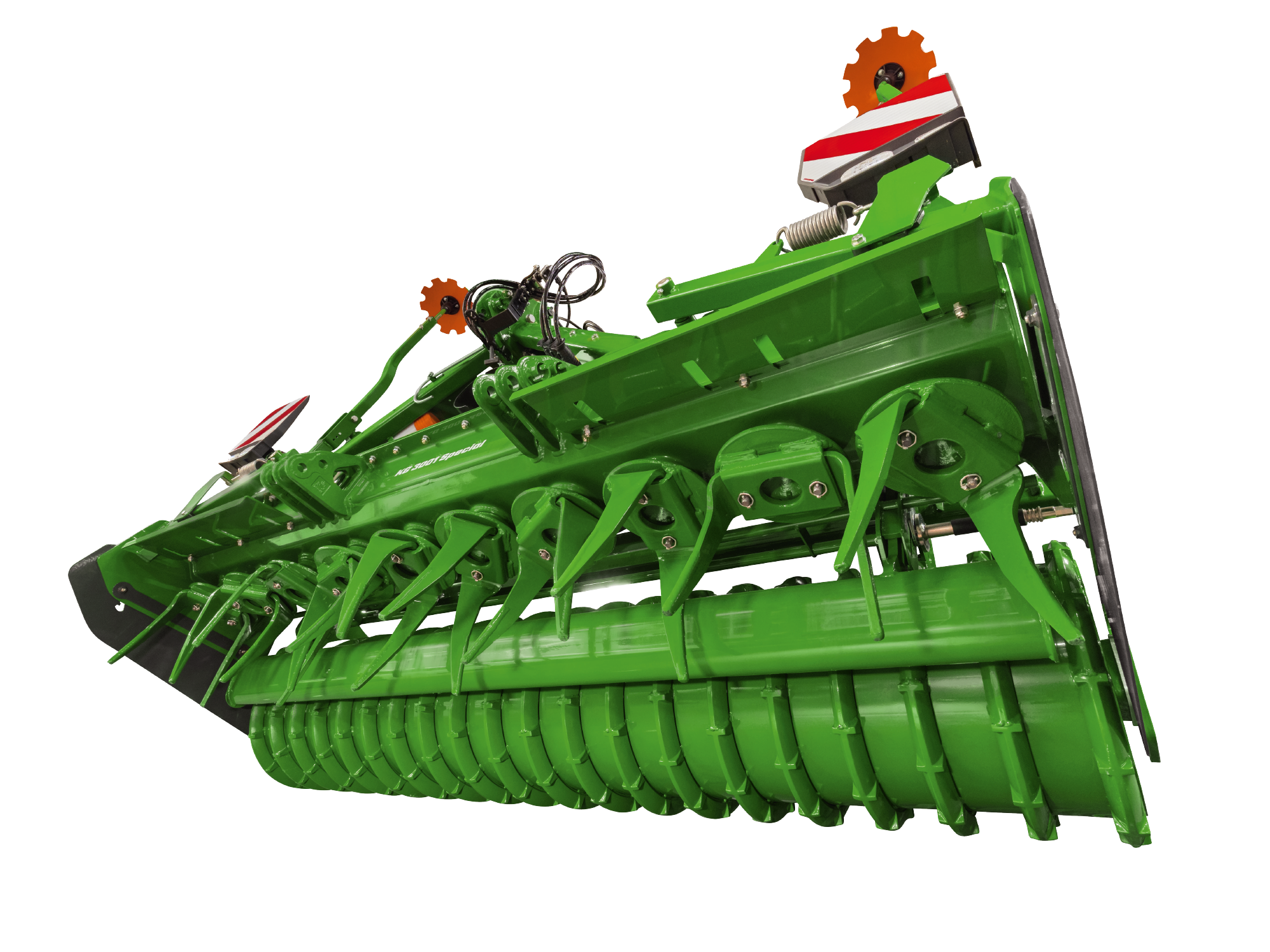

The reliable, long-distance runner: KE rotary harrows, in working widths of 2.5 m and 4 m, ensure, especially on light soils, a very good seedbed. Either in solo operation or in combination with a power harrow-mounted seed drill, a fine crumbled seedbed is achieved with the trailing tines.

KE 2501 Special: for tractors up to 102 kW/140 PS

KE 3001 Special: for tractors up to 102 kW/140 PS

KE 3001 Super: for tractors up to 135 kW/180 PS

KE 4001 Super: for tractors up to 135 kW/180 PS

The benefits of the KE Special and KE Super:

- Fine-crumbed seedbed

- Easy rotor speed change by simply repositioning the bevel gears in the gearbox

- Light, handy and at the same time robust – thanks to the double-skinned trough design