TECHNOLOGY THAT SUITS.

Maximum performance with the Precea precision air seeder.

INTUITIVE

Simple and self-explanatory operation with the AMAZONE AmaTron 4 ISOBUS terminal. Extremely easy adjustment of the PreTeC mulch seeding coulter, since all the required settings can be made without using tools.

HIGHLY PRODUCTIVE

Maximum areas covered at a working speed of up to 15 km/h, a working width of 3 to 12 m and up to 6,000 litres of seed.

PRECISE

Exact seed spacing in the row thanks to the excellent over-pressure singling system and optimised plant distribution when seeding around a bend with CurveControl. No overlaps or gaps in wedge-shaped fields thanks to the individual single-row shut-off for seed, fertiliser and micro-granules via the AmaTron 4 ISOBUS operator terminal.

"Seeding technology that understands me!"

Farmers and contractors know their land, crops and targets inside out. Soil, climate, machinery and inputs – all these factors contribute to that unique agricultural fingerprint.

To get the most out of every farm, AMAZONE offers the Precea precision air seeder – an implement that provides the perfect solution for every individual challenge.

The Precea is precise, highly productive and user-friendly. The Precea enables you to master the seeding demands, today and tomorrow – for high yields, healthy crops and professional establishment.

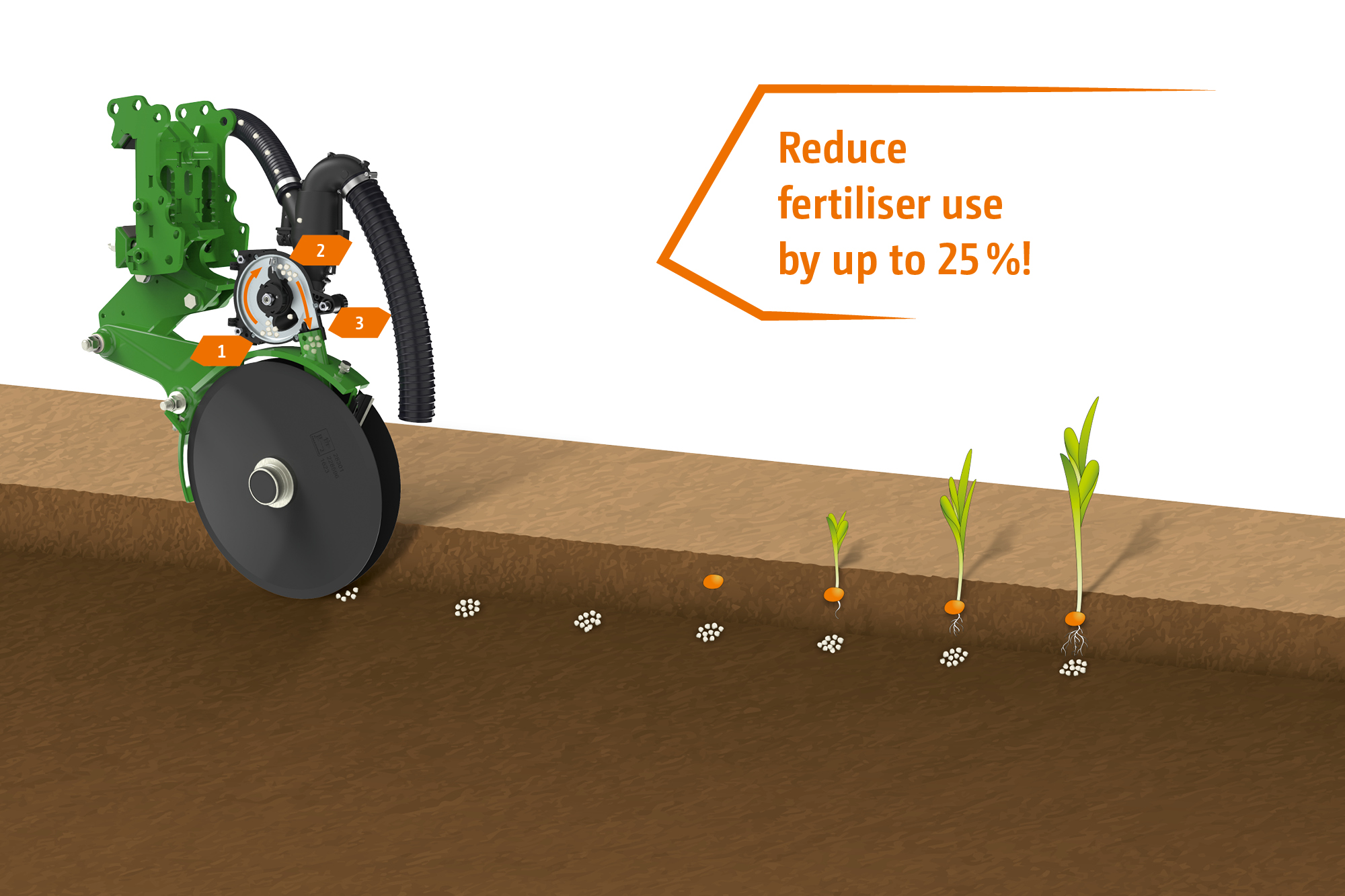

Discover the advantages of the Precea now and unlock the full potential of your farm with the technology of the future. Save money with the new FertiSpot system, which enables you to reduce fertiliser usage by up to 25%.

My precision conveying system

CENTRAL SEED SUPPLY

Seed is always available when needed

Seed is delivered from the central hopper to the reception units, mounted above each sowing unit, via an air stream. These reception units act as a temporary store for the seed. The control system is self-regulating: If the hopper is so full that the green grid on the inside is completely covered with seed, the air flow is restricted - no more seed is transported from the central hopper to the sowing units. As the seed is taken down into the singling chamber, the reservoir empties and the air flow is reactivated. The Central Seed Supply System thus ensures that the sowing unit supplies itself with seed without the need for electronic control.

LONG OPERATING PERIODS

Twin-chamber fertiliser hopper with weighing system:

The fertiliser hopper with a capacity of up to 6,000 litres means drilling for long periods without refilling.

The fertiliser hopper can be conveniently filled in a matter of minutes from a big bag over the side of the machine. The fill level indicator can be supplemented by camera monitoring inside the hopper. The hopper's weighing system also enables exact monitoring of the fertiliser applied.

FLEXIBLE APPLICATION

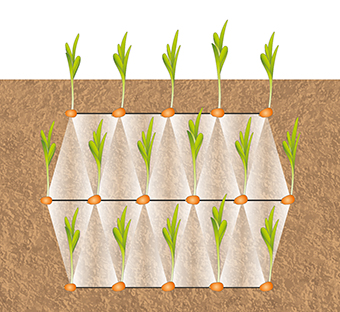

MultiBin: By using up to 3 hoppers, several materials – (1) seed and (2) fertiliser or (3) micro-granules – can be applied simultaneously and flexibly. This saves on passes and increases fertiliser effectiveness through precise under-root fertilisation.

My precision placement system

CURVE CONTROL

Optimised seed placement when driving round bends

The individual electric metering drive to each row makes it also possible to maintain an evenly-spaced placement across the entire working width, even when driving round bends. The even spacing allows all plants to be adequately supplied with nutrients. This results in more uniform crops and ensures even ripening.

Customised machine software, developed by AMAZONE - for ideal communication between machine and driver.

PRECISE SEED SPACING

SmartControl: over-pressure in the singling chamber pushes the seeds up against the rotating singling disc, so that they are carried round. As they rotate, the seeds, held in place under pressure, run past 3 stripper fingers which ensure that any extra seeds are knocked off and singled. The stripper fingers are automatically adjusted to make it easier for the driver.

COMFORTABLE CONTROLS

ElectricDrive: ElectricDrive utilises a separate electric motor for each singling unit. This allows the desired seed rate to be conveniently set via the terminal. An activation button also allows each singling disc to be checked.

RELIABLE MONITORING

Infrared sensor: the firing of each individual seed is registered by the infrared sensor in the opto-sensor and transmitted to the AmaTron 4 as a signal. The signal is then processed for use by e.g. the intelligent SmartControl stripper adjustment,.

FLEXIBLE CROPS

The centralised singling discs are customised for different operating conditions or seed characteristics, such as different thousand grain weights and forward speeds.

IDEAL PLACEMENT DEPTH

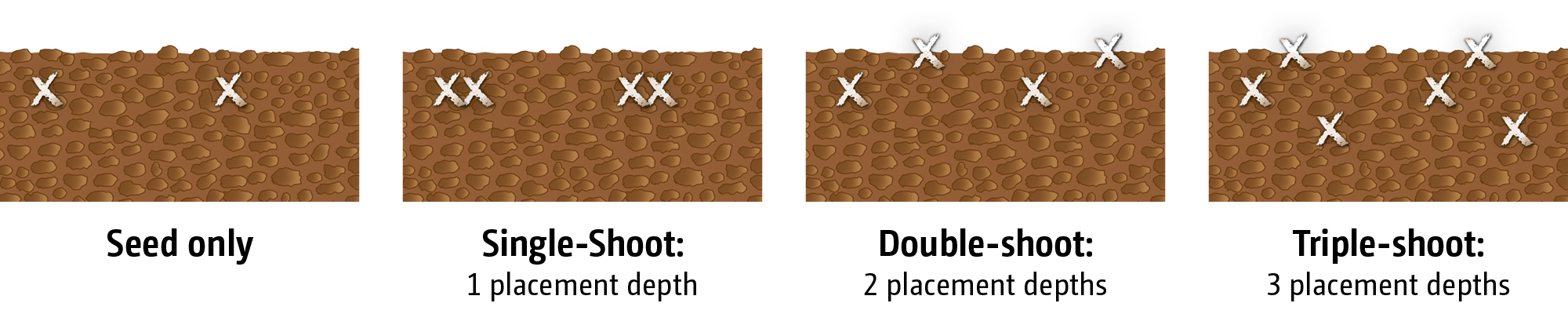

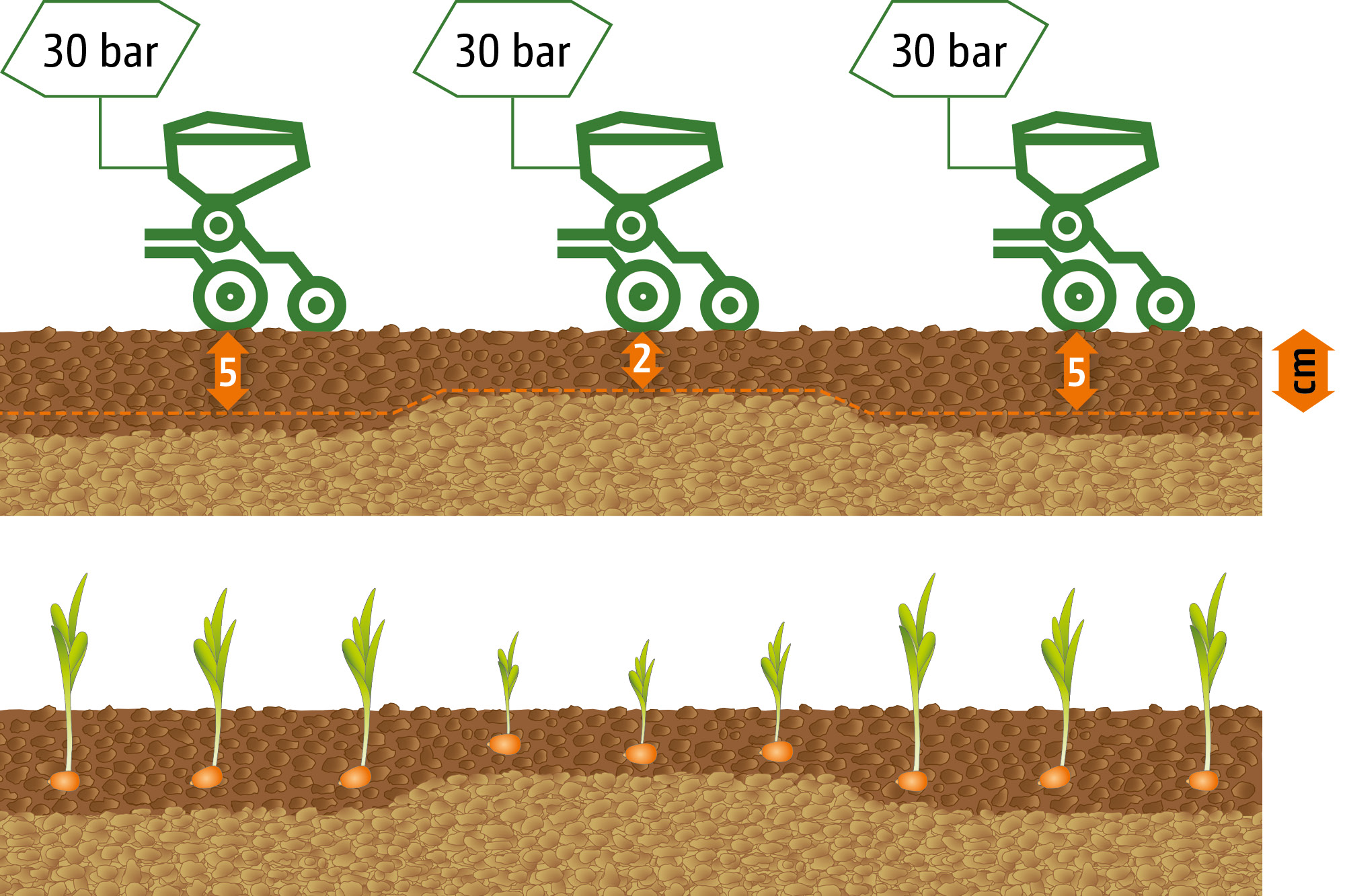

MultiShoot: Simultaneous application of different materials. Simultaneous application of different materials, such as seed, fertiliser or micro-granules, at the same placement depth or different placement depths in the soil.

My precision coulters

SMOOTH RUNNING AT MAXIMUM SPEED

PreTeC: No matter whether it is used for conventional sowing after the plough or for mulch sowing, the PreTeC mulch seeding coulter is perfect for precision seeding. Benefit from first-class, consistent seed placement accuracy and increase your yields.

UNIFORM PLACEMENT DEPTHS

SmartForce: The coulter pressure is set hydraulically via the ISOBUS terminal – automatically based on the actual coulter pressure required during work. The particular feature with this system is that the driver does not need to stipulate the coulter pressure, but rather they set the desired contact force on the terminal. This contact force is checked by measuring pins when in the field. If a deviation from the predefined contact force on the PreTeC coulter is registered due to changing ground conditions, the SmartForce hydraulic system readjusts the coulter pressure accordingly.

UNIFORM PLACEMENT DEPTH

The basic settings of the Precea are mostly made directly on the PreTeC mulch seeding coulter without the need for tools. The placement depth, the contact pressure of the press rollers and their angle of contact for precise reconsolidation are very easily set using the numbered scales.

My precision fertilisation

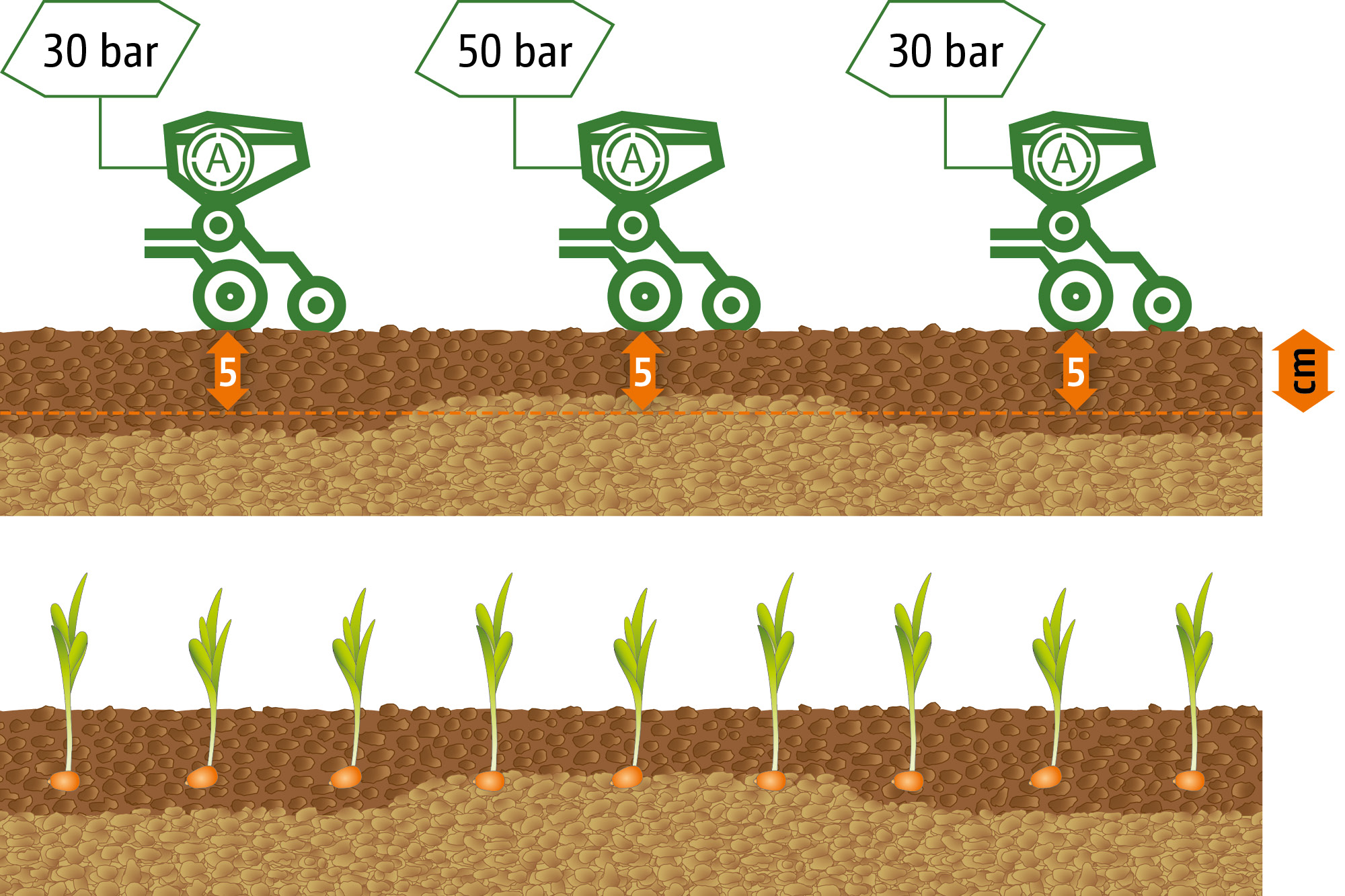

HOW FERTISPOT WORKS

- From the metering system, fertiliser continuously enters the top of the portioning chamber.

- The fast-rotating portioning rotor is driven by its own motor matched to the speed of the singling unit. The fertiliser granules in the portioning chamber are collected and amalgamated during one revolution of the portioning rotor. A consolidated fertiliser portion is produced.

- The fertiliser portion is shot into the propulsion channel and placed precisely in the soil via the outlet of the portioning chamber.

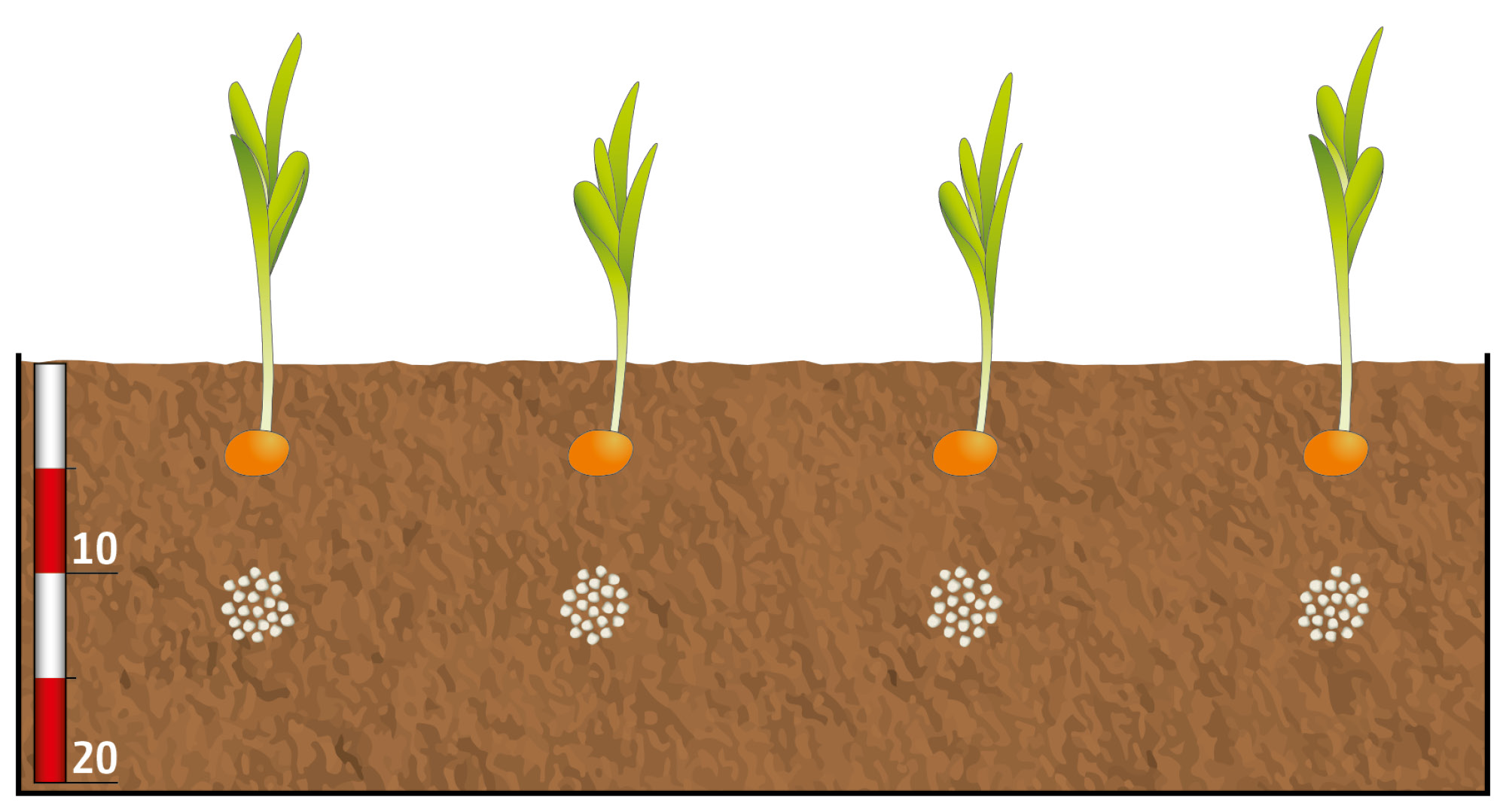

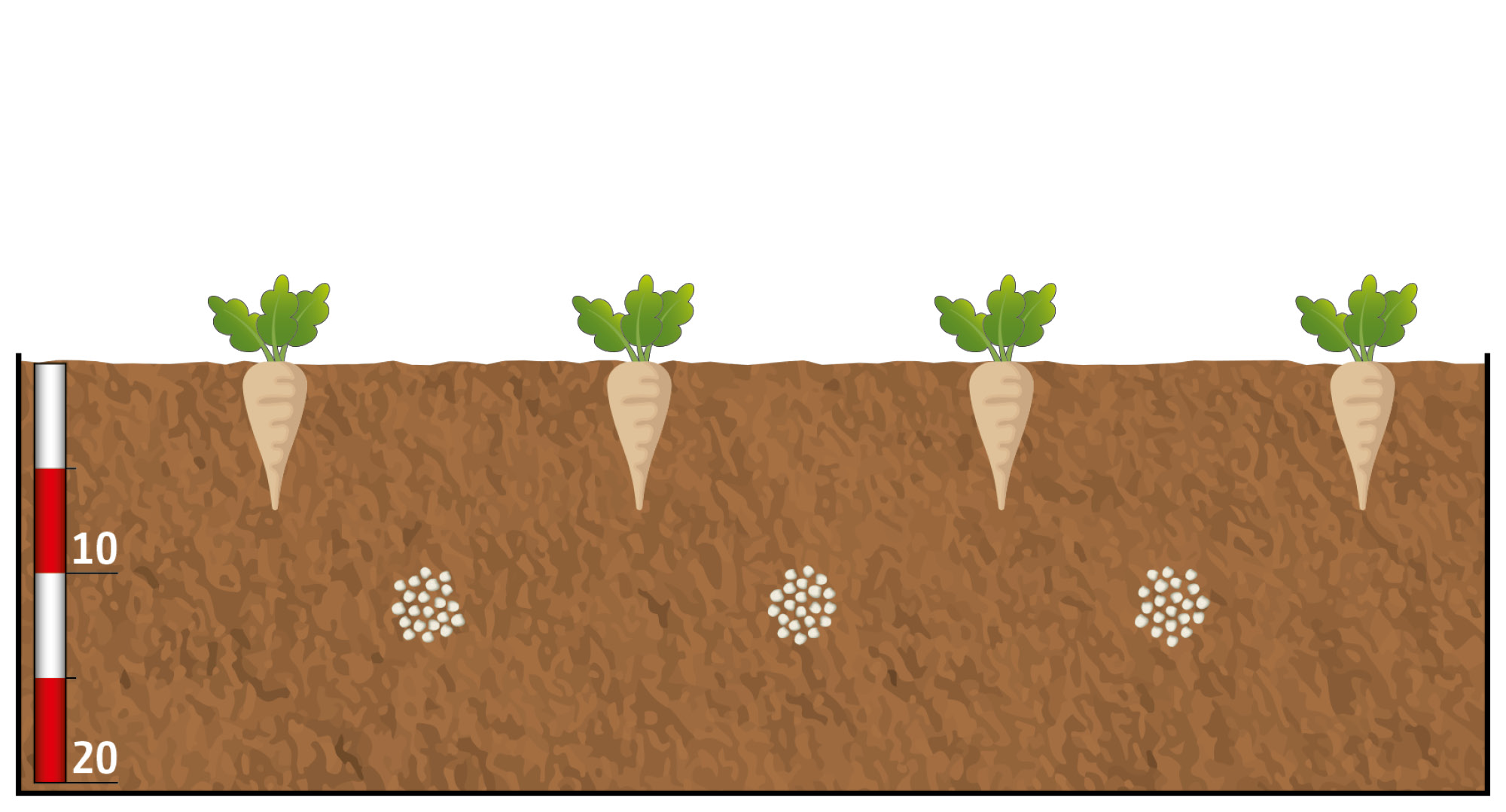

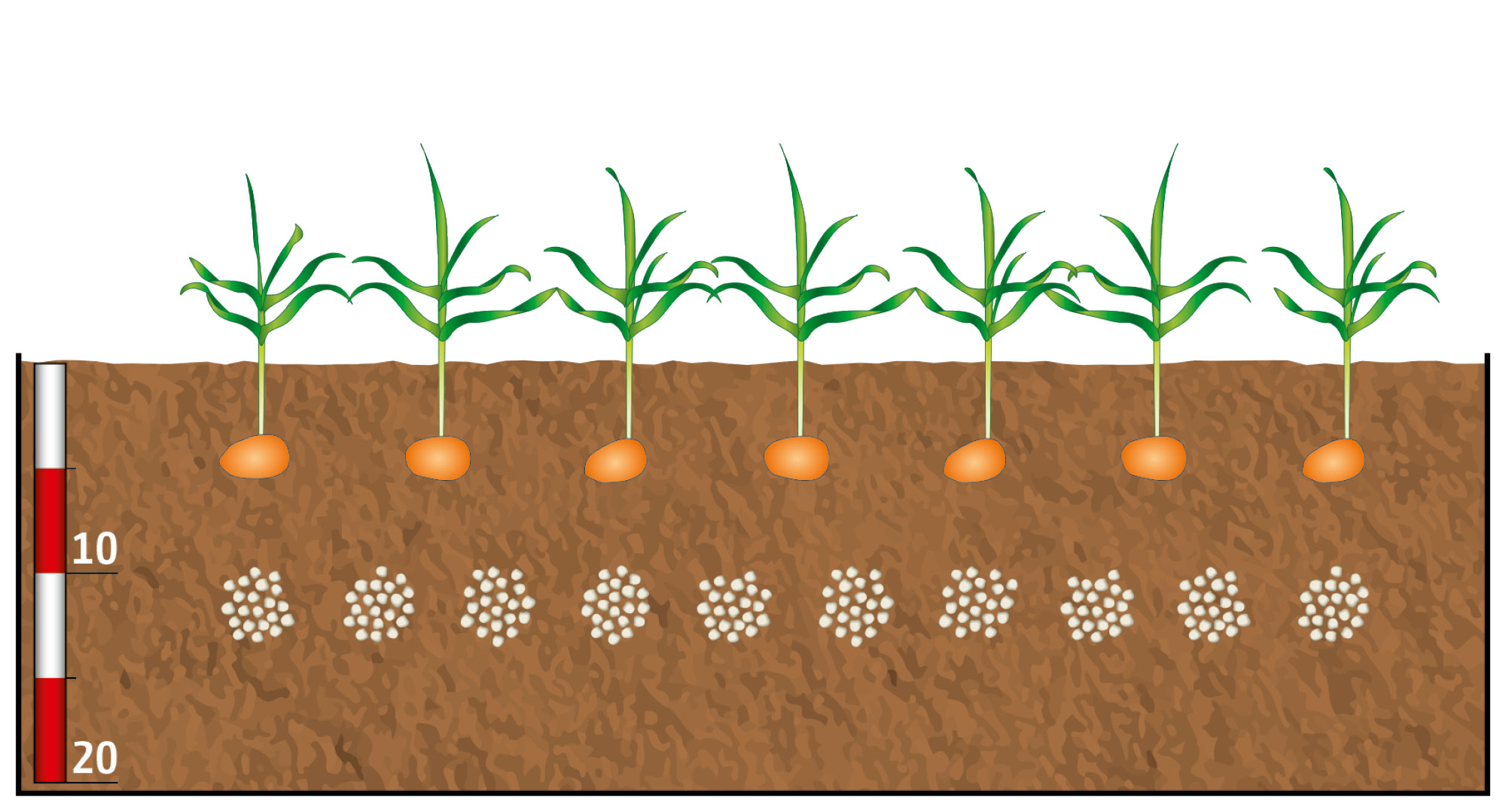

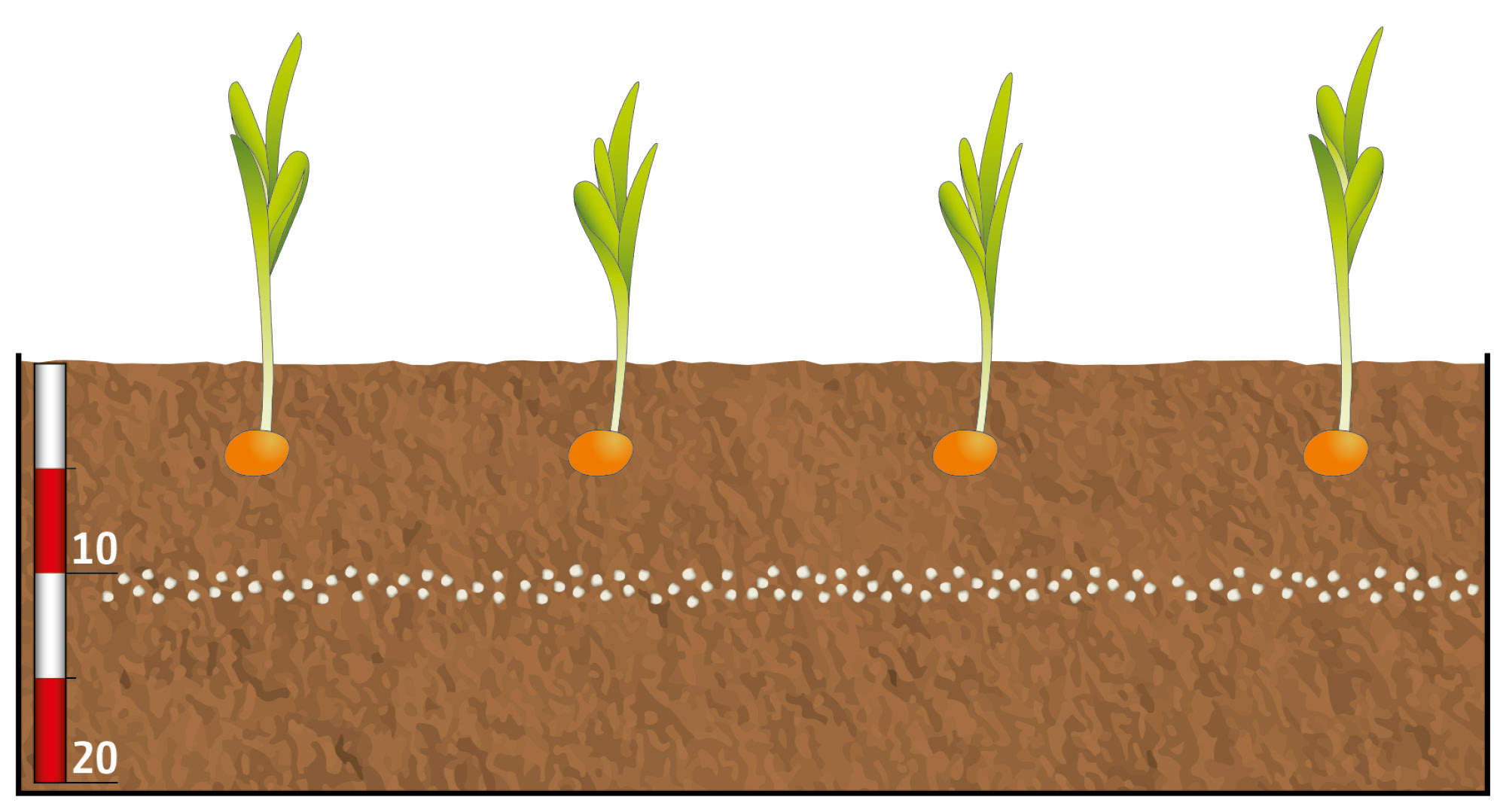

SPOT-SPECIFIC, UNDER-ROOT FERTILISATION

FertiSpot for the Precea takes under-root fertilisation to a new level of precision and efficiency.

With FertiSpot, the under-root fertiliser is deposited as a concentrated nutrient supply under the seed - exactly in the plant's future root zone. The young roots make optimum use of the fertiliser, since the fertiliser remains available for a longer period, even under dry conditions. Inefficient fertilisation resulting from the leaching of the fertiliser in between the plants is prevented. This increases nutrient efficiency in comparison with fertiliser applied in a band.

Optimum early development of the plants with FertiSpot under-root fertilisation ensures good yields, especially during dry summers. The same level of yield from normal band fertiliser application is achieved - but by using up to 25% less fertiliser. Reducing the amount of fertiliser, whilst maintaining the same yield, increases profitability and improves working conditions in areas with higher fertilisation requirements.

My precision terminal

MAXIMUM USER-FRIENDLINESS

The AMAZONE AmaTron 4 operator terminal offers a range of functions that go beyond the ISOBUS standard, such as freely configurable displays and individual user interfaces for each driver.

MAXIMUM EXTENSION

AmaTron Twin App Easily visible extension of the display for the map view with GPS functions and which can also be operated from a mobile device.

PART-AREA, SITE-SPECIFIC APPLICATION

MultiMap: Both seed, fertiliser or micro-granule rates can be applied to specific areas within a field, adapted to the different yield potential - independently of each other, based on up to 3 application maps with the GPS-Maps&Docs licence, using the AmaTron 4.

MULTIPLE APPLIED MATERIALS

MultiBoom: Automatic time-delayed switching on or off of the seed, fertiliser and micro-granules via GPS-Switch pro with AmaTron 4 prevents overlapping or misses on the headland.

SINGLE ROW SHUT-OFF

MultiSwitch: In order to avoid over- or under-sowing in critical areas, each row can be switched on and off precisely using single row shut-off in combination with the GPS-Switch basic software licence in the AmaTron 4 operator terminal - separately for seed and fertiliser or for the addition of micro-granules.