New Precea 7500-TCC precision air seeder

New levels of equipment: leading star clearers, twin tyres, FertiSpot

The Precea 7500-TCC precision air seeder with a 3,000 litre fertiliser hopper and a working width of 7.5 m is available in 2 different versions, just like the Precea 6000-TCC with its 6 m working width.

Centralised and decentralised seed hoppers

The Precea, with a central seed hopper with 850 litre hopper capacity and the Central Seed Supply (CSS) seed feed system, holds the seed in the large hopper and feeds the seed to the individual sowing units as and when required. Centralised filling via Bigbags and the large hopper capacity make the Precea 7500-TCC a high performing machine for large farms and contractors working large areas.

AMAZONE also offers the Precea 7500-TCC with seed hoppers on the individual sowing units. The Precea, with its 70 litre seed hoppers, is ideal for small areas with frequent seed changes, or for carrying out variety trials.

AMAZONE introduces new equipment options for its trailed precision seeders. For the spring season, Precea models can be ordered with leading star clearers. This optional equipment is an ideal tool for removing straw residues and organic matter from around the sowing coulter area, especially when mulch sowing.

Leading star clearer with wide guide rollers

AMAZONE offers the new leading star clearers in a manually adjustable version or, alternatively, with pneumatic adjustment - in front of the fertiliser and seed openers so that the organic matter is not pressed into the seed furrow. This optimises the result and creates an ideal seed furrow. The star clearer reliably clears the surface. Thanks to their own inherent weight and the large, wide guide rollers, they are guided neatly within the furrow.

For the manual version, the height of the clearing tools is adjusted using the tool provided and can be locked in place using the quadrant.

The pneumatic version of the star clearer can be adjusted in height centrally on the implement and it can also be deactivated. Its own inherent weight and the pneumatic pressure cylinder ensure smooth running at high speeds.

New twin tyres for the trailed Precea

For models with narrower row spacings of 45 cm and 50 cm, AMAZONE offers its trailed precision air seeders with twin tyres for the 2025 spring season.

The twin tyres enable uniform sowing conditions for crops such as oil seed rape, beet and soya in closer row spacings. The 4 tyres, with a tyre size of 270/95 R44, run exactly between the seed rows. Reconsolidation of the soil in the seed row is thus avoided.

FertiSpot for the coupled fertiliser coulter

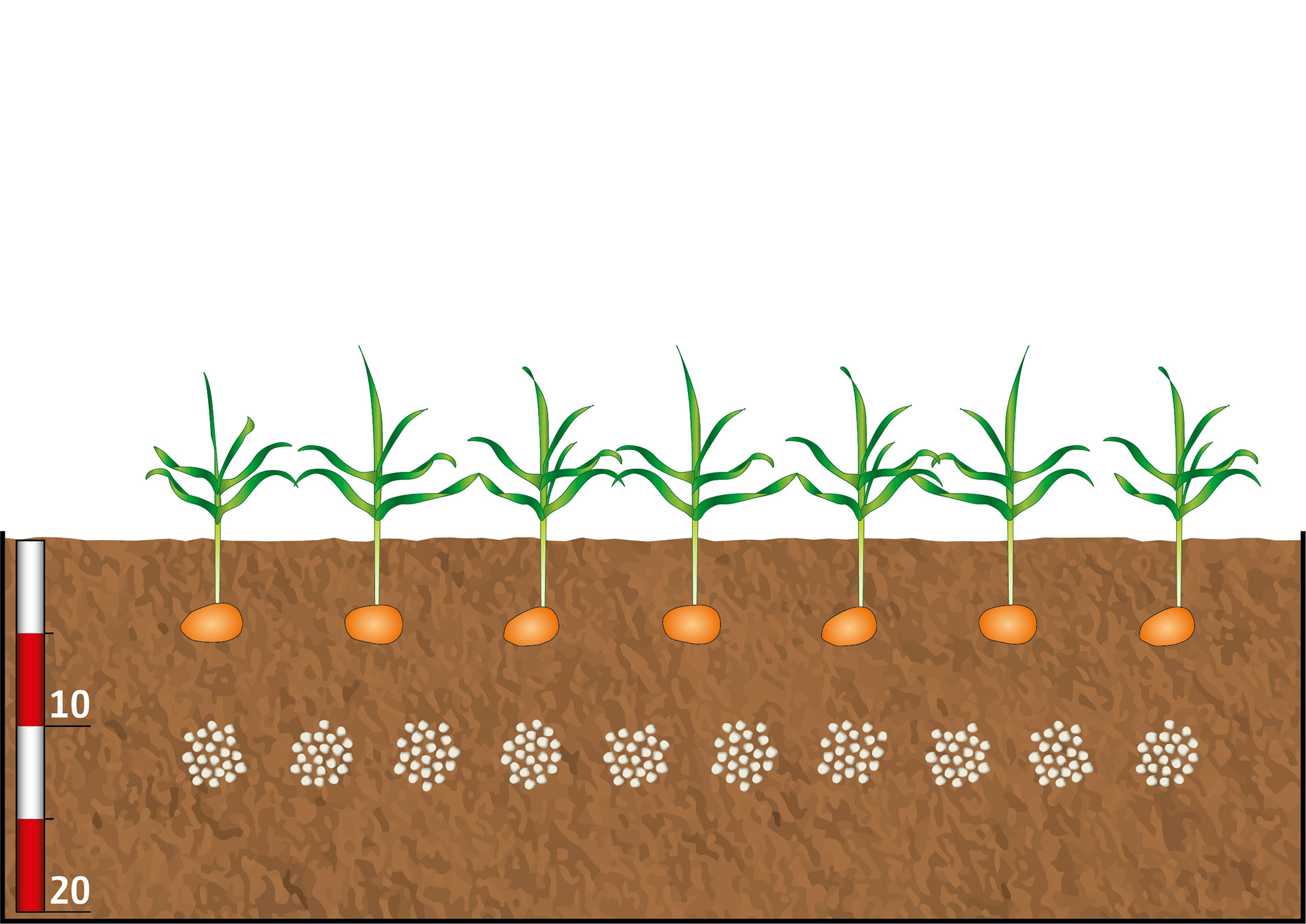

FertiSpot allows the fertiliser to be delivered both as a portion directly under the plant as well as a dose between the seeds. AMAZONE now offers the fertiliser dosing system for the coupled fertiliser coulter, and therefore also for the mounted Precea models.

Thanks to the innovative fertiliser portioning system, up to 25 % of the usual amount of under-root fertiliser can be saved. At the same time, however, the yield remains consistent. The concentrated fertiliser application directly under the maize seed means that the fertiliser is fully available. This allows the rate to be reduced.

AMAZONE further developed the system so that the FertiSpot can also be used on other crops.

The system, which is integrated into the ISOBUS software, can be adjusted easily from the tractor cab. The driver can choose between spot mode, multi-spot mode and band application.

FertiSpot - under the seed or between the seeds

For use in beet, the spot can be applied precisely between the seeds of the crop. This prevents the fine roots from being sorched. FertiSpot is also suitable for use on oil seed rape. In the so-called MultiSpot application, many small doses of fertiliser are placed under the rape seed.

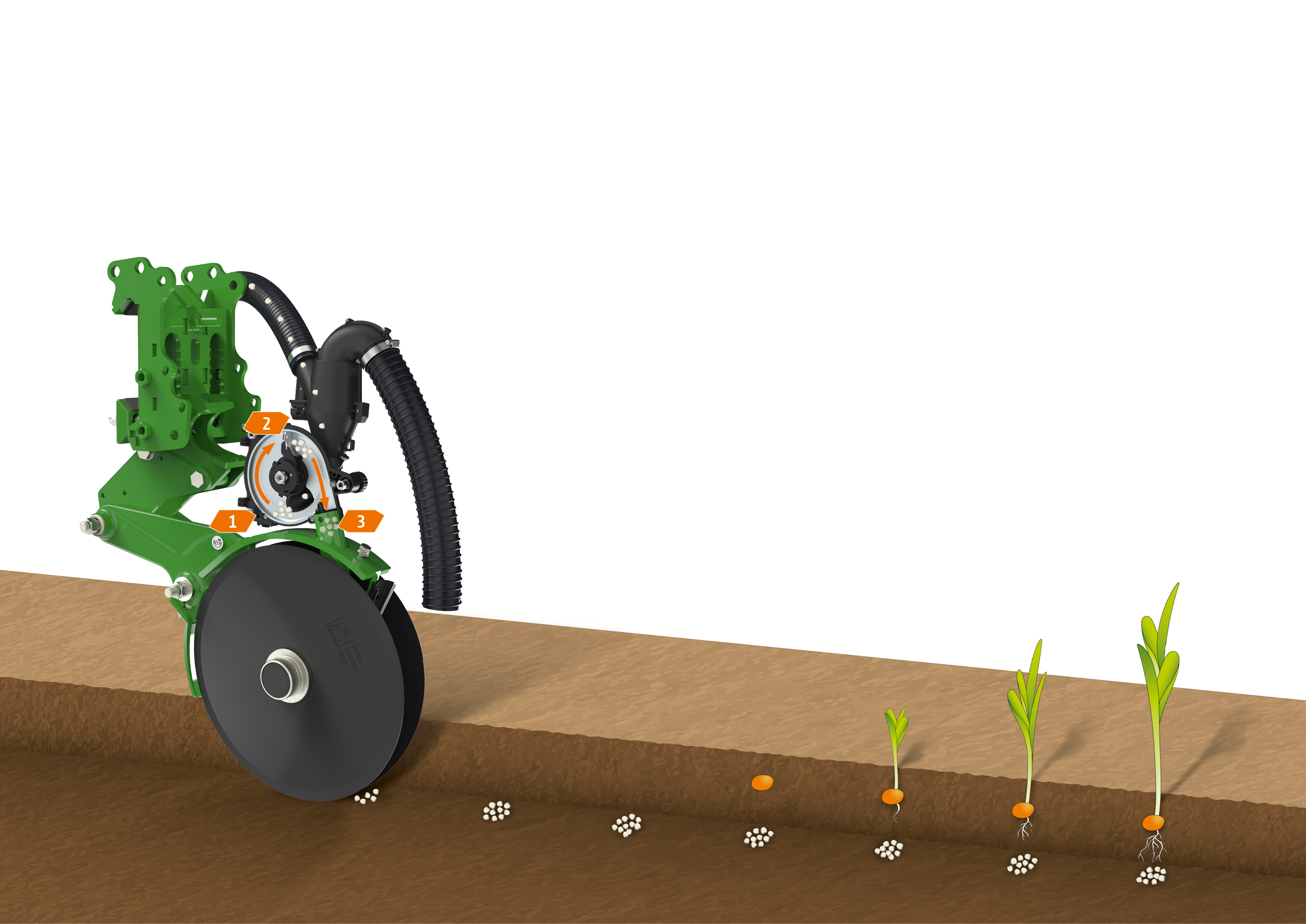

How FertiSpot works

- From the metering system, fertiliser continuously enters the top of the dosing chamber.

- The fast-rotating portioning rotor is driven by its own motor matched to the speed of the singling unit. The fertiliser granules in the portioning chamber are collected and amalgamated during one revolution of the portioning rotor. A consolidated fertiliser portion is produced.

- The fertiliser dose is placed precisely into the soil via the outlet of the dosing chamber via the conveying section, synchronously with the application of the seed.

- Precea 7500-TCC in a working width of 7.5 metres for increased output

- Extension of equipment options to include star clearers, twin tyres and the FertiSpot system for optimised results

- Efficient under-root fertilisation for precision seeding over large areas possible with the FertiSpot system on mounted precision seeders

Gallery