New AMAZONE Teres 200 mounted reversible plough

Complete Teres 200 plough range:

New stepped variant complements the Vario ploughs

With the Teres 200, AMAZONE offers a modern plough that is characterised by its high efficiency, robust construction and practice-oriented levels of equipment. The range comprises of 2 variants: The Teres 200 V and Teres 200 VS Vario ploughs with variable hydraulic working width adjustment introduced at the beginning of the year, and now the new Teres 200 and Teres 200 S stepped ploughs with manual working width adjustment to be presented at Agritechnica 2025. Both versions are designed for tractors up to 200 hp and are available in 4 or 5 furrow versions.

2 variants - tailored to different requirements

The new Teres 200 and Teres 200 S stepped variants add an economical alternative to the product range for farms that do not need to adjust the working width on the move. The furrow width can be set manually in fixed steps of 35, 40, 45 or 50 cm. These variants are aimed in particular at farms that rely on simple, robust machinery and still want to benefit from tried and tested AMAZONE quality.

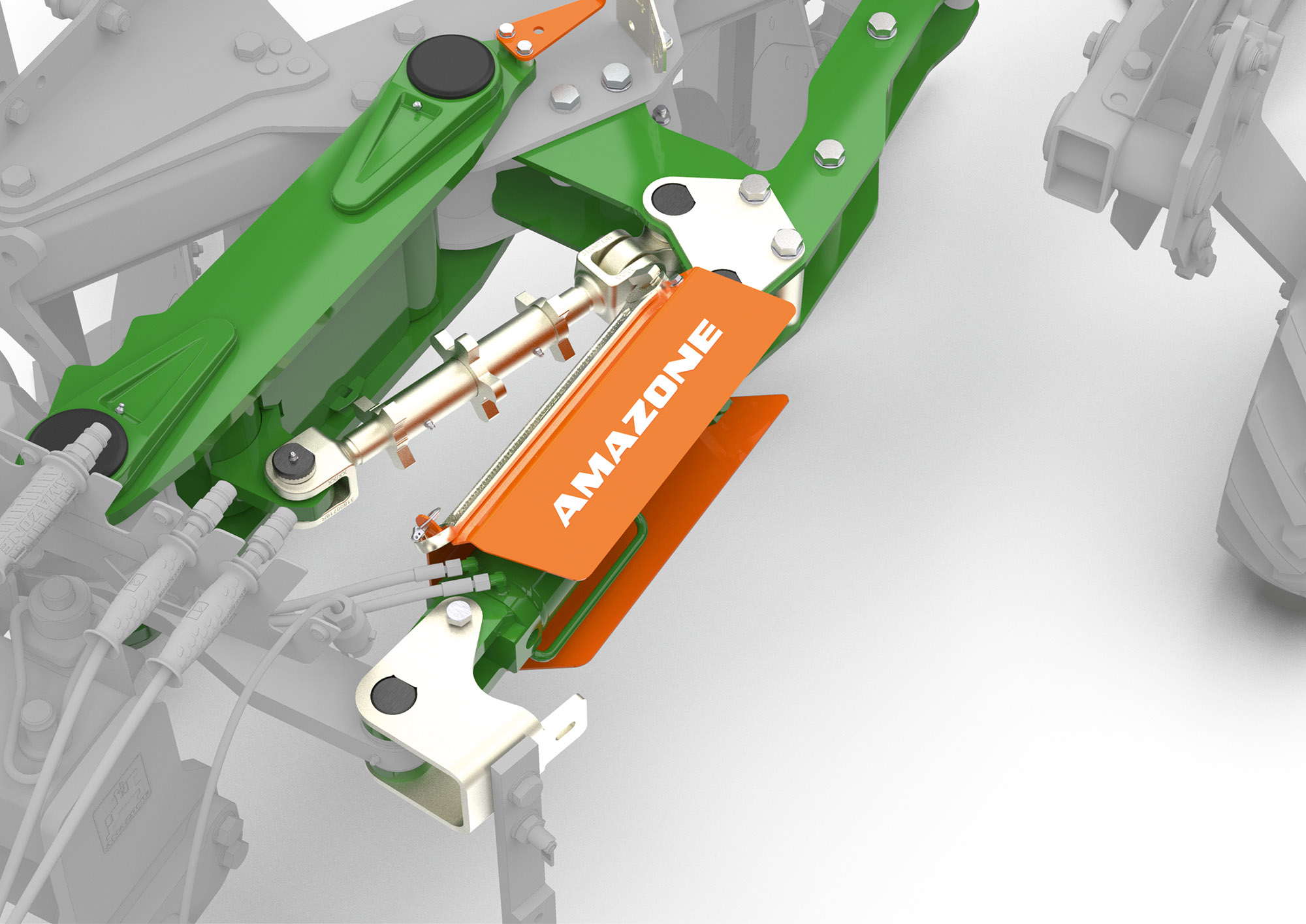

The Teres 200 and Teres 200 S use the familiar parallelogram arrangement in the adjustment centre. It enables automatic adjustment of the pull point when the front furrow is changed, without the need for any additional setting.

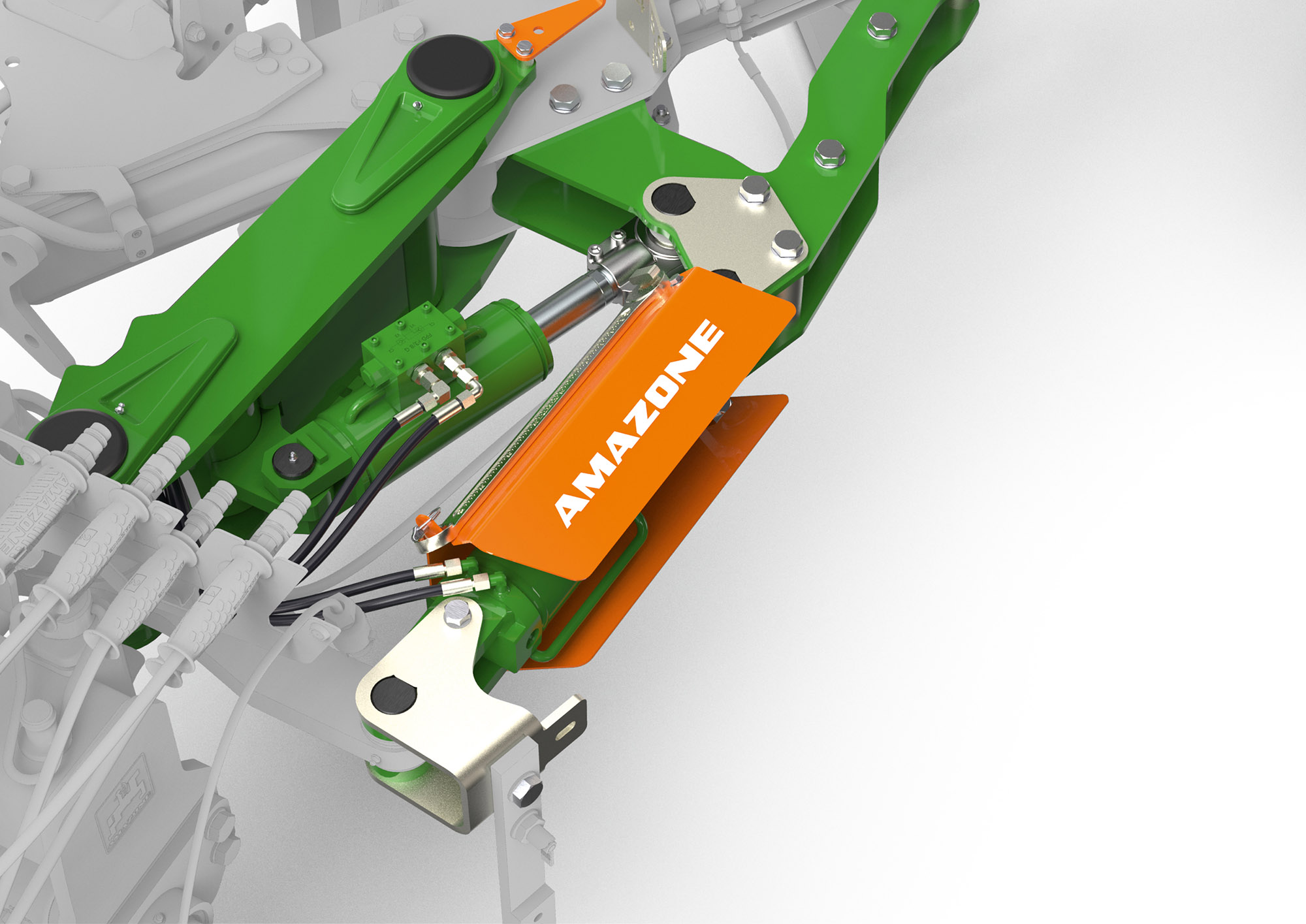

The Teres 200 V and Teres 200 VS are equipped with infinitely variable hydraulic working width adjustment and front furrow adjustment as standard. This means that the front furrow can be adjusted conveniently from the cab as well as being adapted to suit varying soils and when working on slopes. The driver can also very easily adjust the working width hydraulically and infinitely-variably from 33 cm to 55 cm per body using the tractor hydraulics.

The AutoAdapt automatic front furrow adjustment offers a particular advantage in terms of comfort and precision. This means that the front furrow is also automatically adjusted precisely when the overall working width is changed. This perfect adaption is carried out via the parallelogram and via the hydraulic connection between the furrow width cylinder and the front furrow cylinder. This generates perfect matching up of the ploughing when changing the furrow width, thus producing a tidy working profile. In addition, AutoAdapt also has a positive effect on fuel consumption, since the angle between the plough and the lower link cross-shaft, and thus the pull line, does not change.

Both variants are characterised by their ease of handling, their exceptionally light pull and consistent working profile. The choice between the Vario ploughs and the stepped variant enables customised adaptation to operational requirements and investment strategies.

SpeedBlade plough bodies:

efficient, durable and fuel-saving

A central feature of the Teres ploughs is the SpeedBlade plough body with its enlarged front shin on the mouldboard. This body has been specially developed for use at higher working speeds. The main wear point automatically shifts further and further back towards the centre of the plough body when increasing the working speed from say 6 km/h up to 10 km/h. As a result, the main wear point of the SpeedBlade plough body is on the enlarged front shin of the mouldboard and not back on the main part of the slatted or solid mouldboard, even at these higher speeds. This means that only the front shin of the mouldboard needs to be replaced in the first instance on the Teres when used at higher speeds. This enormously reduces wearing costs compared to other designs.

The unique ©plus hardening process forms the basis for premiium quality during the manufacture of Teres wearing metal parts, resulting from the additional introduction of carbon. Very high hardness and thereby a smooth surface is achieved on the front of the mouldboard. This ensures a longer service life. The back remains relatively soft and is therefore extremely tough and impact-resistant.

Comfortable working depth adjustment

The furrow depth adjustment is either carried out manually or hydraulically via the support wheel. AMAZONE offers both side-mounted pendulum support wheels and combination support wheels as well as the rear pendulum support wheel for the Teres models. The Teres range also includes various tyre types with a variety of diameters and profiles for precise depth control and effective self-driving. A specially developed AS tyre with dimensions of 785 x 350 mm is available for particularly demanding conditions for depth control.

Overload safety protection for extreme applications

Overload safety protection on the Teres 200 and Teres 200 V is executed via tried-and-tested shear bolts, having a shear force of 4,400 kg. The Teres 200 S and Teres 200 VS, with its hydraulic overload safety protection, ensures smooth and material-protective working under arduous operating conditions. Trip forces of up to 2,000 kg can be infinitely adjusted either centrally or separately on each individual body, depending on the operating conditions. The maximum lift stroke is 40 cm, so that the bodies can avoid large obstacles, even at deep working depths. The bodies can also swing to the side. The plough body is gently pushed back into the soil via the hydraulic cylinder. As an additional safety feature, each leg has a separate shear bolt.

Maximum durability and lightness

The 120 x 120 x 10 mm square section beam gives the Teres a high level of rigidity whilst maintaining low weight. The bearing-mounted ProtectShaft cross-shaft with integrated lower link balls ensures low levels of wear and maximum durability. The pivot bearings have a dampening, material-protecting effect and protect the plough when turning over on the headland and when driving on the road. Thanks to the integrated balls, the durability of the cross-shaft is increased markedly on account of the larger diameter.

The large, hollow turnover shaft with a diameter of 120 mm allows two bearings of the same dimensions. This markedly increases durability. In addition, the benefit of the hollow shaft is that the hydraulic pipes can be routed neatly through it.

The Teres also scores with its gentle SmartTurn turnover system. The built-in frame swivel cylinder ensures a low-wear turning process in the shortest possible time without changing the furrow width.

Options for every application

Optional soil engaging tools allow the new mounted reversible plough to be universally adapted to all operating conditions. For example, various skimmers or trash boards are available for the clean incorporation of large amounts of organic matter. The use of landside protection improves plough guidance on slopes. A sword landside is available as an option for regions with stony and heavy soil. It protects the edges of the front shin of the mouldboard from wear and cuts a clean furrow wall. Disc coulters can be fitted to the last plough body for exceptionally clean furrow clearance. For simultaneous reconsolidation, AMAZONE offers the Teres 200 with a swivel press arm for working with a packer.

- High levels of efficiency owing to high forward speeds with minimal wear thanks to the SpeedBlade plough body with enlarged front shin on the mouldboard and ©plus hardening process

- No pull point adjustment required when changing the furrow width setting

- High durability thanks to the bearing-mounted ProtectShaft cross-shaft

- Simple adjustment of the front furrow thanks to optional infinitely variable hydraulic adjustment

- Selection of various different side-mounted and rear mounted wheels for good transport on the road and safe and tidy working on the field

Gallery