AMAZONE ZA-TS 01 AutoSpread

A new era of precision: the self-adjusting fertiliser spreader

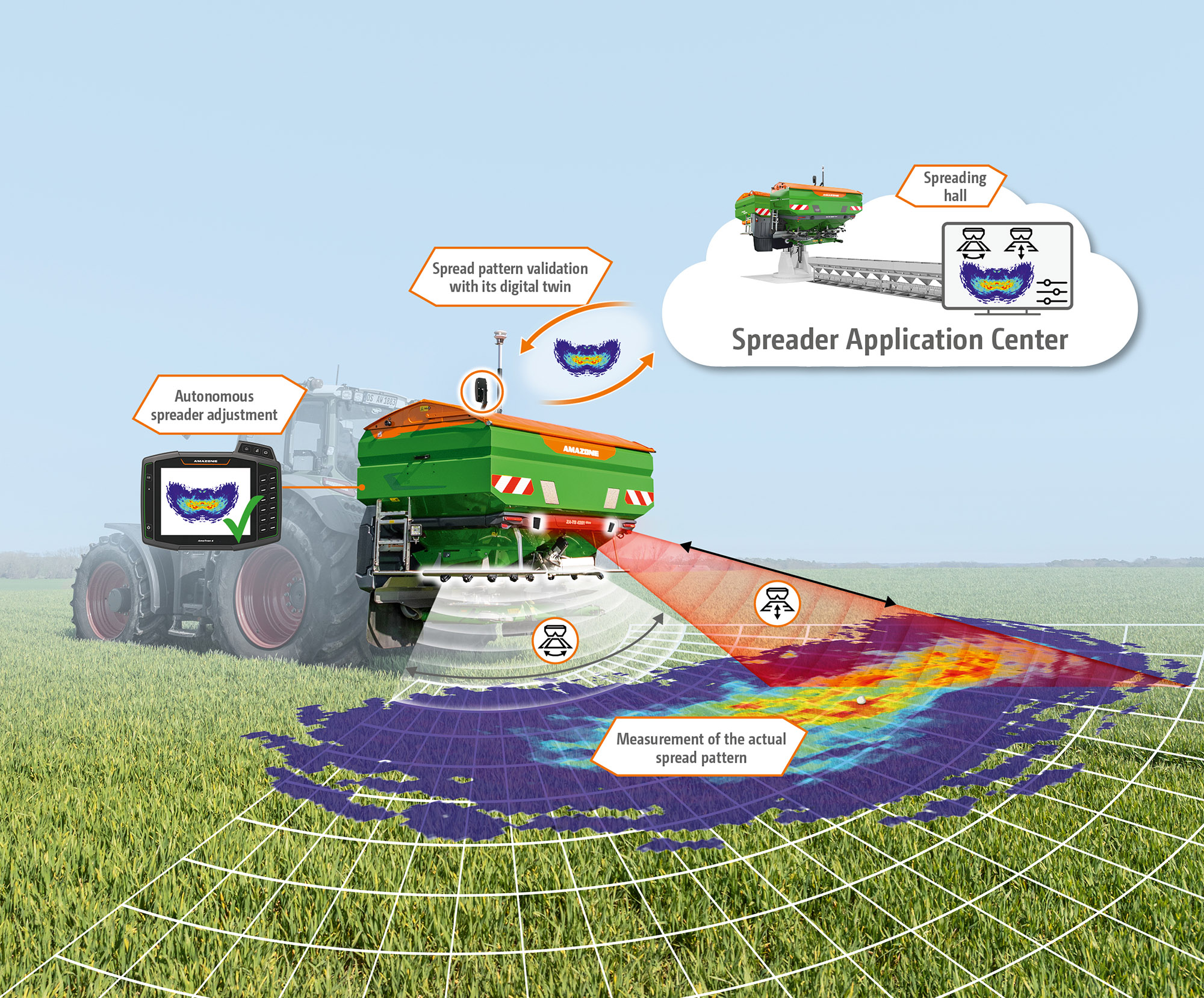

With the new ZA-TS 01, AMAZONE is offering a technology which revolutionises fertiliser spreading. After years of development and successful trials in the field on over 100,000 hectares, the unique AutoSpread feature sets new standards in precision and automation. An autonomous solution for optimum fertiliser distribution is being implemented for the first time. AutoSpread monitors the actual spread pattern of the fertiliser and automatically adjusts the settings to achieve optimum distribution. Combined with the intelligent online connection to the AMAZONE Spreader Application Cente, the actual spread pattern is permanently validated, meaning that the operator no longer has to make any settings. This solution is unique and offers a particularly high degree of innovation.

The central challenge of fertilisation: having the correct setting

The central challenge of precise fertilisation has always been as to whether the centrifugal broadcaster is set correctly. The global fertiliser market is characterised by a growing product diversity and an increasing heterogeneity in fertiliser types and fertiliser batches, which further increases the complexity for farmers. Incorrect spreader settings can lead to uneven distribution of the fertiliser, which in turn results in reduced yields and loss of quality. This not only results in economic losses but also impairs sustainability and efficiency in agriculture.

AMAZONE has always been known for its innovative developments in the field of fertilisation. For example, Argus, an award-winning system for monitoring the direction of throw, was presented for the first time back in 2007. Argus therefore set a milestone in the optimisation of mineral fertiliser distribution and made it possible to compensate for the influence of changing fertiliser qualities for the first time. However, precise pre-adjustment to the respective fertiliser was also necessary here. This was the first step towards automation. But Dr Heinz Dreyer (1932 – 2023), AMAZONE's third generation Managing Director, already had a bigger vision back then: the self-adjusting fertiliser spreader. AMAZONE is now offering the solution in the shape of the new ZA-TS 01 AutoSpread.

Precise and permanent – perfect lateral distribution in seconds

The ZA-TS 01 is the guarantee to outstanding precision. For the first time, AutoSpread measures the actual flight characteristics of the fertiliser and adjusts the spreader automatically. The view behind in the field that has been missing so far is now a thing of the past.

Existing systems such as ArgusTwin already enable the direction of throw to be measured, but the actual throwing distance of the fertiliser remains unknown. If an incorrect throwing direction is set as the target variable, this will result in incorrect application with a loss of yield and quality.

The throwing distance of the fertiliser can only be determined under stationary laboratory conditions – up to now. However, this is essential for all spreading situations in the field. An incorrect throwing distance not only leads to a loss of accuracy in the normal spread pattern but also to incorrect switch-on and switch-off points in Section Control.

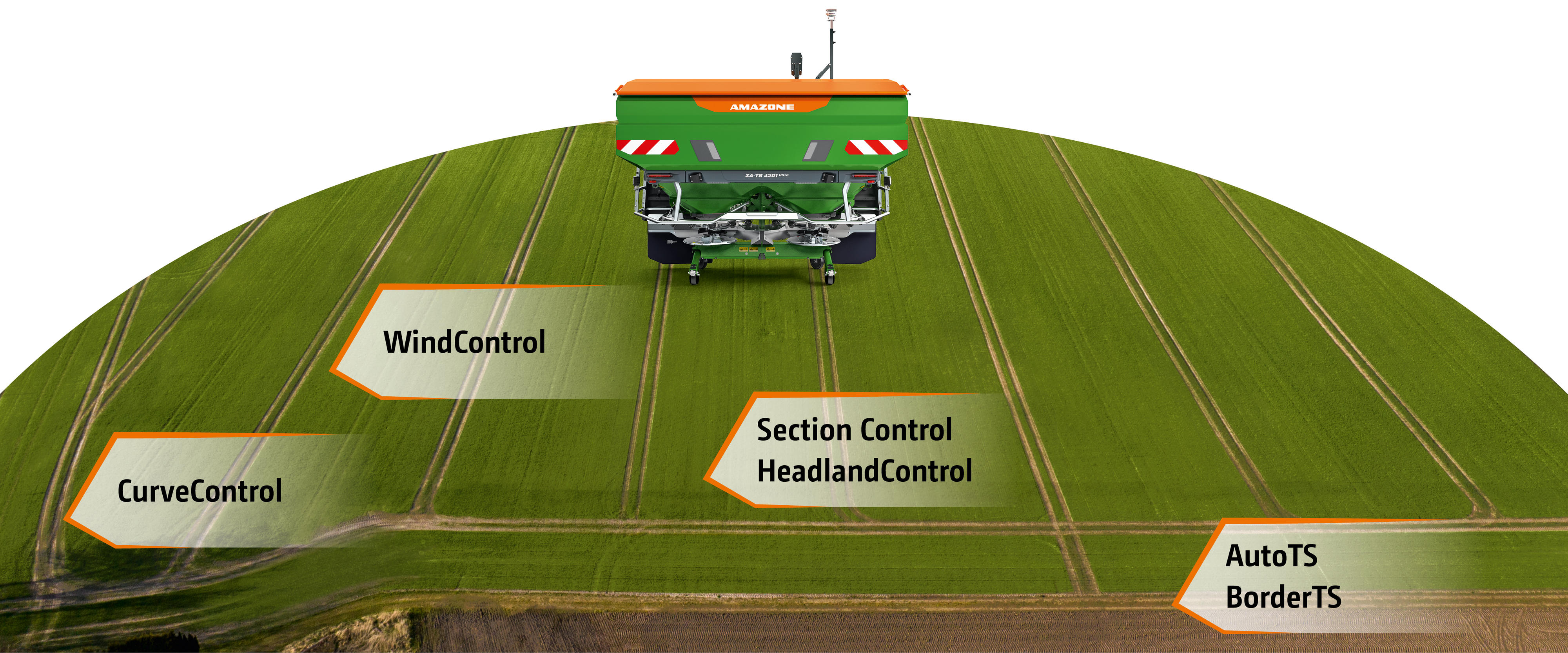

Thanks to the additional AutoSpread sensors, it is now possible for the first time to determine not only the throwing direction but also the throwing distance and consequently the actual spread pattern in the field. This turns the ZA-TS 01 AutoSpread into a mobile spreading hall. Whilst the innovative solutions for the various individual situations such as HeadlandControl, WindControl (according to Prof. Dr. Karl Wild of the University of Applied Sciences, Dresden) or Section Control used to be individual solutions, they are now optimally integrated via AutoSpread for the first time. For example, in the case of Section Control, AutoSpread automatically determines the actual switch-on and switch-off points or adjusts the control process for the current fertiliser via the WindControl wind sensor. In combination with the new border spreading system, the distribution is also optimised in the field boundary area. With AutoSpread, all systems are more accurate than ever before and all areas of the field are fertilised in the best way possible .

Reliable and intelligent – reliability of application thanks to its digital twin

AutoSpread not only ensures maximum precision but also reliability of the spreading process as well as the intelligent monitoring of lateral distribution. Whilst it was previously only possible to test the spreading quality at a selective point via manual test kits in the field, AutoSpread enables continuous validation of the actual spread pattern. Thanks to the online connection to the AMAZONE spreading hall (SAC) via the AmaConnect Unit, the fertiliser's digital twin is automatically transferred to the spreader in the field. The actual collected data is now compared with the known spread patterns of its digital twin using an AI-supported algorithm and is permanently validated in real time. Incorrect fertiliser settings are reliably detected and the spread pattern is perfectly adjusted. Thanks to the intelligent connection, this is also possible offline in the event of a network failure, so reception problems in the field are not a problem.

With the help of this innovative spread pattern monitoring, AutoSpread can also reliably detect worn or defective spreading vanes before the spread pattern deviates. The quality of the lateral distribution is always in view via a display on the terminal. If anomalies occur or the measured spread pattern does not match the reference of its digital twin, AutoSpread specifically prompts you to check with the EasyCheck digital test kit and ensures that any errors are quickly rectified where necessary. The system therefore provides the spreading process with a high degree of reliability through continuous validation of the autonomously set parameters. The use of spreader testing to check the distribution is significantly reduced and unnecessary spreader tests are a thing of the past. This saves time and ensures maximum convenience.

The intelligent connection and linkage of implements to the AmaConnect data platform opens up new possibilities. The basis is created for further smart functions with a focus on decision support, automation, process monitoring or quality assurance. Real-time data, sensor systems and digital assistance systems create more transparency and efficiency in use. In combination with AutoSpread, the entire spreading process, including the physical spreader tests, is displayed online. This increases application reliability, particularly in large farms.

- Self-adjustment of the spreader through measurement of the actual spread pattern

- Permanent optimisation of all spreading scenarios – including automatic determination of the actual switch points for Section Control

- Continuous validation of the spreading accuracy and intelligent online connection to the Spreader Application Center

- Time saving due to the elimination of unnecessary spreader testing in the field

- Warning of faulty or defective spreading vanes before spreading errors occur

- Overall reliability thanks to detailed evaluation of the fertiliser application process in the AmaConnect data platform

The key component: the new software in the ZA-TS 01

In addition to AutoSpread, the ZA-TS 01 is characterised first and foremost by the new software. The completely newly developed software comes with numerous digital innovations that make its use even more intuitive and efficient. In addition to the easy-to-use interface in a modern design, the completely redesigned border spreading and the integration of CurveControl are worth highlighting.

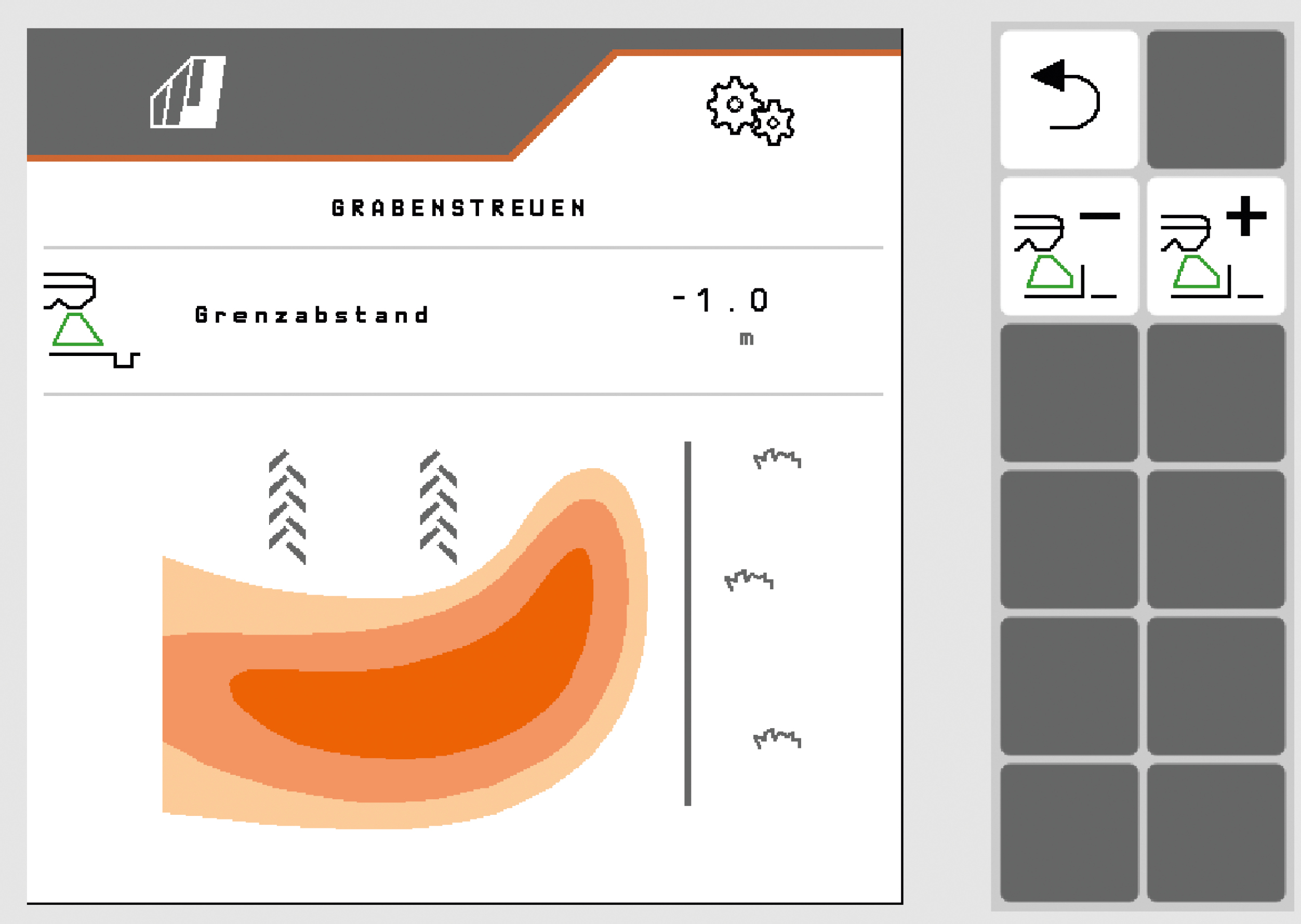

Border spreading is newly thought-through – simply enter the distance to the field boundary and drive off

A basic distinction is made between side, border and water course spreading. The various processes differ in that they are adapted to the respective border situation, in order to ensure legally compliant fertilisation. Today, the farmer has to adjust the respective settings on the basis of the setting chart. Since important factors such as the spreading disc speed and spread rate reductions are interrelated, the reciprocal effects on the distribution at the boundary are difficult to understand. There is no practical option for optimisation.

This is now provided entirely by the software in the ZA-TS 01. Simply enter the desired distance to the field boundary and drive off: the spreader automatically calculates the correct settings and optimally matches the parameters. This is made possible by a new user interface. Depending on the situation and the farmer's individual requirements for fertiliser distribution at the boundary, the desired result is simply entered in the software and the spreader calculates all the settings automatically. A diagram on the terminal visualises the distribution at the boundary clearly and comprehensibly.

As well as being easier to adjust, the proven AutoTS border spreading system now includes the delivery point in the settings. This enabled further optimisation of the border spread patterns of the ZA-TS, which were already very good.

Legally compliant water course spreading with the correct documentation

The legally prescribed distances from boundaries vary depending on the location and must be complied with, especially in the case of water course spreading. Here, the variable input of the distance to the field boundary in metres offers practical and precise compliance with the regulations whilst at the same time achieving the best possible spreading results.

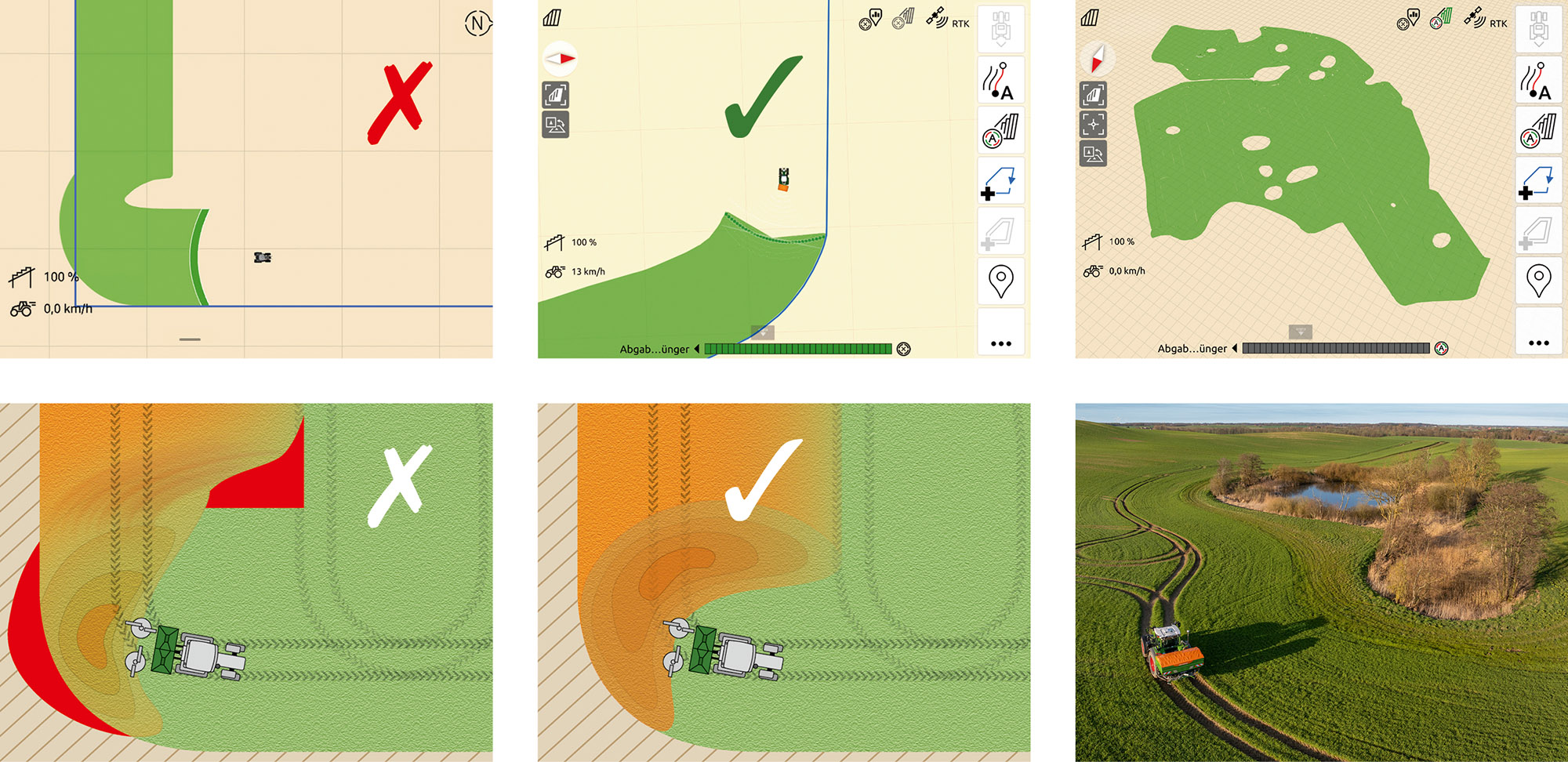

The new software in the ZA-TS 01 ensures correct documentation. During water course spreading, the distance to the field boundary is not only variably adjusted, it is also automatically documented correctly. The software adjusts the working width as appropriate, both in the GPS view and in the documentation. This ensures complete and reliable documentation. For example, if the working width is reduced by 3 metres on the boundary side, this is also correctly displayed in the as-applied map.

Complete integration of the BorderTS border spreading system

For even more accurate border spread patterns, the BorderTS deflector, which has already achieved outstanding results directly at the boundary with the current ZA-TS, has been fully integrated in the new ZA-TS 01. Thanks to an electric actuator, the deflector can be conveniently activated from the terminal and swivelled into the spread fan. The associated backward spreading from the tramline with AutoTS has also been optimised: it now has its own shortkeys in the user interface, making operation even more intuitive.

Correct documentation is also consistently implemented here: deleting fields that have been already spread or other workarounds are a thing of the past. Both BorderTS and the associated AutoTS only document half the working width in the GPS menu. This ensures complete documentation, even when using a border spread deflector. The settings for the border spread deflector are automatically determined by the software, so that precise and simple handling is possible. AMAZONE therefore offers farmers an even more efficient solution for precision spreading directly at the boundary.

The ZA-TS 01 Ultra will be initially only available in limited numbers and in hopper capacities of 4,200 and 5,000 litres. A full market launch, in all levels of equipment, will take place in 2027.

Excellent CurveControl increases fertiliser efficiency

In addition, CurveControl, which was presented at the last Agritechnica and won a silver medal, has been integrated in the ZA-TS 01 Ultra for curve compensation. In addition to the new software, the swivel range of the delivery system has been structurally enlarged and the frame adapted. This allows the spread fan to be guided further over the centre. This ensures precise fertiliser distribution even when cornering. This not only increases efficiency, it also minimises the risk of over- or under-fertilisation.

Precise fertiliser application even around curves

CurveControl adjusts the lateral distribution to the various cornering speeds and corrects the movement of the spread pattern when driving around bends. The throwing distance of a centrifugal broadcaster is up to twice the working width and the application area is many metres behind the spreader depending on the fertiliser. In addition, the spread fan has a kidney shape, which leads to the spread fan swinging out at the field boundary and therefore to fertiliser application outside the field boundary. This must be avoided at all costs with a view to resource conservation and application legal requirements.

A sensor mounted on the spreader detects the acceleration and swivelling movement of the spreader and adjusts the delivery point in real time as well as the shutter slide, irrespective of the side. This steers the spread fan and guides it behind the spreader. Under- and over-fertilisation, which are undesirable from an ecological and economic point of view, are minimised and inadvertent application outside the field boundary when cornering is prevented. CurveControl also shows its strengths in combination with HeadlandControl, the headland extension for optimising the switch points. This can lead to negative switch-off points with certain fertiliser and working width combinations despite HeadlandControl. In such cases, CurveControl compensates for the final swivel movements and guarantees perfect distribution.

In addition to the optimisation of fertiliser distribution, the graphic display in the GPS view is also important. In conjunction with AmaTron 4, the swivel movement is reliably recorded, resulting in uniform map coverage. Unwanted white areas are now a thing of the past. This means that Section Control works more reliably. Unintentional opening of the metering shutters is prevented.

With its automation in combination with innovations in border spreading, CurveControl and documentation, the ZA-TS 01 represents the next generation in precision and efficiency.

- Precise fertiliser application even around curves thanks to CurveControl

- New intuitive software

- New border spreading setup – simply enter the distance to the field boundary and drive off – optimised border spread patterns and individually adjustable distance to the field boundary

- Complete integration of the BorderTS border spreading system in the machine operation

- Complete and accurate documentation during border spreading – recording of the actual working widths

- Practical transport boxes for the EasyCheck mobile test kit

Gallery