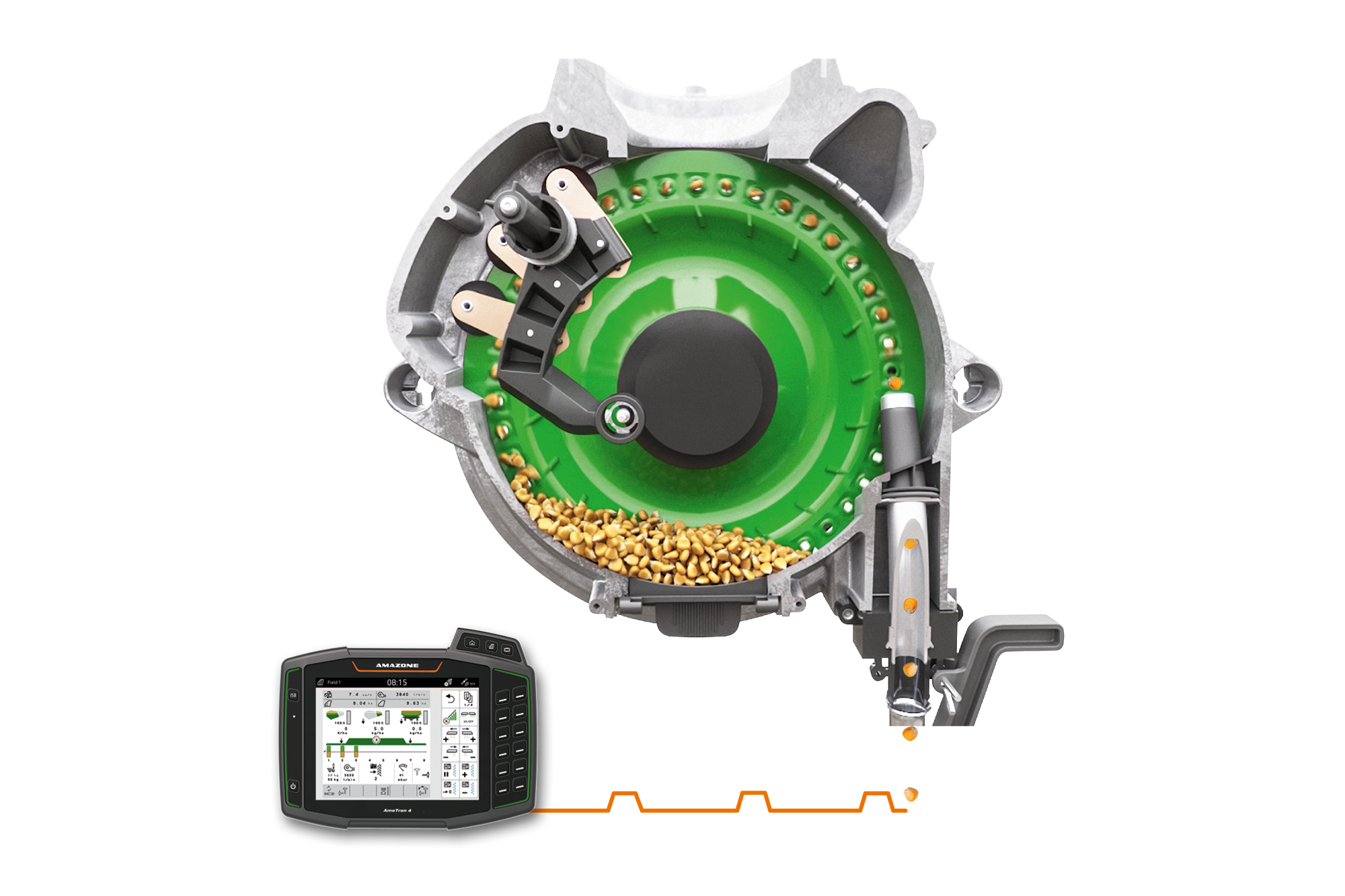

Singling with SmartControl – for precise seed placement

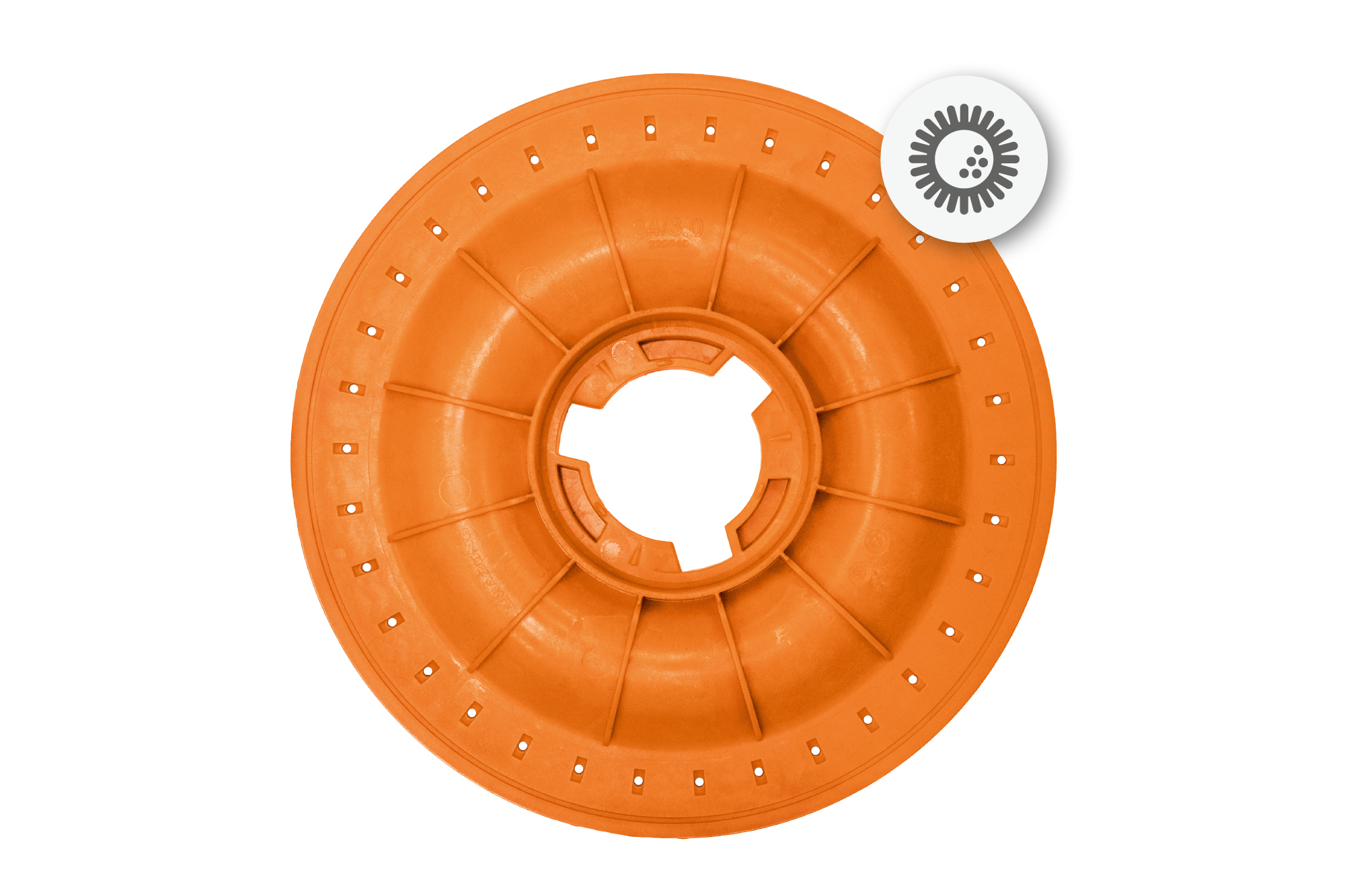

Over-pressure in the singling chamber pushes the grains up against the nap holes in the rotating singling disc so that they are carried round. As they rotate, the grains, held in place under pressure, run past 3 stripper fingers which reliably ensure the stripping and singling of the grains on each hole. Doubles are effectively prevented. The stripper fingers are automatically adjusted via SmartControl to relieve the stress on the driver.

The benefits:

- The stress on the driver is reduced, since the SmartControl constantly handles the adjustment of the 3 seed stripper fingers.

- An increase in yield, since doubles and misses are avoided.

- Savings in time, since manual set-up is not necessary.

ElectricDrive – electric drive of the over-pressure singling

ElectricDrive utilises a separate electric motor for each over-pressure singling unit. The seed rate can thus be adjusted very easily using the terminal. An activation button on each sowing unit makes it possible to check each individual singling disc.

The key feature

Due to the well-thought through design of the centralised singling unit, the singling disc and the singling pressure chamber turn as one.

The advantages of this layout are huge:

- Operation can be carried out exclusively using the tractor's electronic system, due to the fact that only a small amount of torque is required for rotation.

- The seal, which is otherwise subject to excessive wear, is not loaded.

"As the chamber rotates in step with the perforated disc, energy-consuming friction on the pressure chamber seal is avoided."

("profi" – Driving report Precea 4500-2CC Super · 10/2019)

The singled grains are fired precisely

As soon as the singled seeds reach the outlet, the contact pressure is broken and the seed is shot past the opto sensor into the propulsion channel and thus into the soil.

Opto sensor with infrared sensor - reliable monitoring "seed by seed"

The pulse of the Precea - the firing of each individual seed - is registered by the infrared sensor in the opto sensor and transmitted as a signal to the AmaTron 4. The signal is then processed for use by e.g. the intelligent SmartControl stripper adjustment,.

https://www.youtube.com/watch?v=t51LYqTuem4