7 years’ manufacturer guarantee against rusting through in fertilisation

Intro to guarantee against rusting through

7 years’ manufacturer guarantee against rusting through in fertilisation

The best of both worlds - KTL cathodic dip-paint coating combined with powder coating

The paintwork on a fertiliser spreader is exposed to particular demands. The paintwork is intended to protect the spreader from corrosion, especially when handling fertiliser and where moisture is involved. Starting with the 2022 model year, we will using a new painting process for the ZA-V, ZA-TS and ZG-TS fertiliser spreader ranges. This involves, one the one hand, a cathodic dip painting process (known as KTL) for priming to give the best possible protection on the internal surfaces of tubes and box sections and, on the other hand, a powder coating process to create a high-quality visual finish with extra-thick paint providing increased protection against mechanical demands.

No worries - manufacturer guarantee against rusting through

Based on this optimum painting process, AMAZONE is able to offer its customers a manufacturer guarantee of seven years against rusting through, starting with the 2022 model year. From 01/01/2023, customers can apply to have the guarantee activated for ZA-V, ZA-TS and ZG-TS models, starting with the 2022 model year. This is done very simply via the manufacturer’s portal, myAmazone, bearing in mind the terms and conditions stated there. After registration, they can then continue to work without any worries.

Multi-layer painting

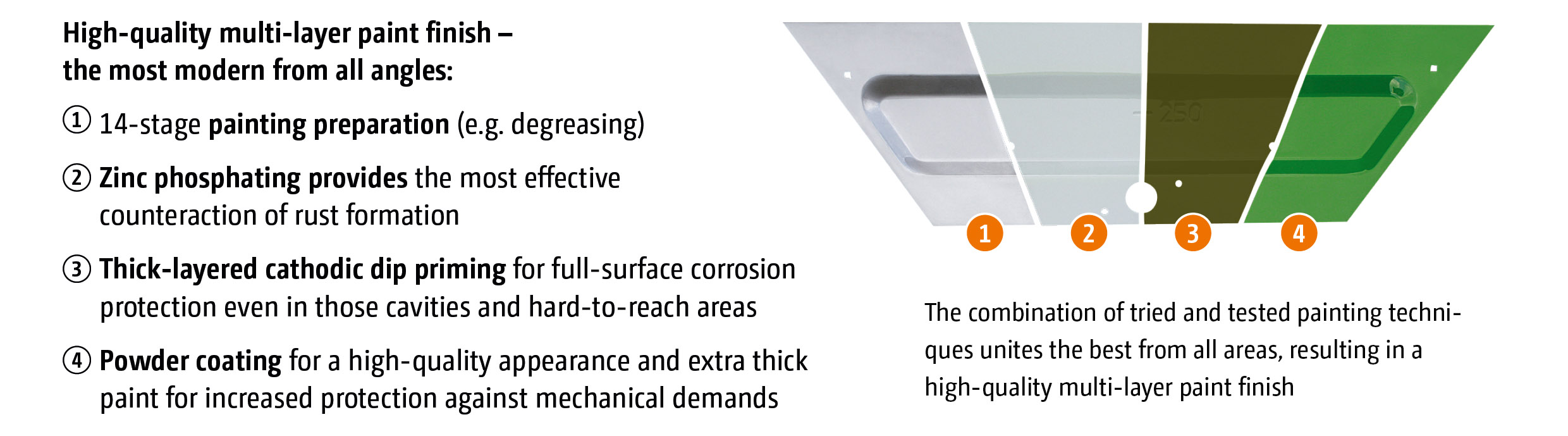

The painting is carried out in four main steps. The particular characteristic of this multi-layer painting process is the combination of cathodic dip primer painting and powder coating. First of all, the carrier material is prepared for painting in a series of 14 stages. This includes multiple etching and degreasing operations, for example. The spreaders are then subjected to zinc phosphating in the next step, in order to prevent the formation of rust in the most effective manner. The third stage includes the thick-layer KTL cathodic dip-paint process. Then, finally, the fertiliser spreaders receive their powder coating. The application of a particularly thick powder coating gives the spreader even better protection against mechanical demands, and they get double effective corrosion protection as a result of the stove-baking process.

Plastic mesh replaces metal mesh

Most of the paint abrasion on a fertiliser spreader takes place on the sieves in the hopper. This generally takes place when filling the spreader as the fertiliser runs through the sieves, which then wears the paint away step by step. The ZA-V and ZA-TS fertiliser spreader ranges, from 2022 model year onwards, will be equipped with the most modern UV and chemical resistant plastic sieves, in order to counteract this wear factor. The sieves can be stepped on, of course, and can be folded up for cleaning, as usual.

Contractual conditions concerning the manufacturer guarantee against rusting through for the model series, ZA-TS, ZA-V and ZG-TS which fall within the contractual warranty period from 01/01/2023.

Visual, superficial defects caused by corrosion are excluded from the manufacturer guarantee against rusting through, even if they cover large areas. The manufacturer guarantee against rusting through can only be invoked during the first 12 months and after acceptance by us. The manufacturer guarantee period against perforation corrosion shall commence the first time the spreader is used.

After use, the AMAZONE machine must be cleaned thoroughly and protected. Outside the period of use, it must be parked in premises that preserve it and protect it from the weather. The machine must be stored away for the winter according to the specifications of the operating instructions.

The manufacturer guarantee against rusting through shall come into force if:

- any corrosion that has occurred has reached a level that causes severe weakening of the frame structure and/or the hopper, or complete rusting through.

- the machine constitutes a hazard to road safety and the machine’s operator.

- the machine’s functionality can no longer be guaranteed due to corrosion damage on the machine’s metal structure.