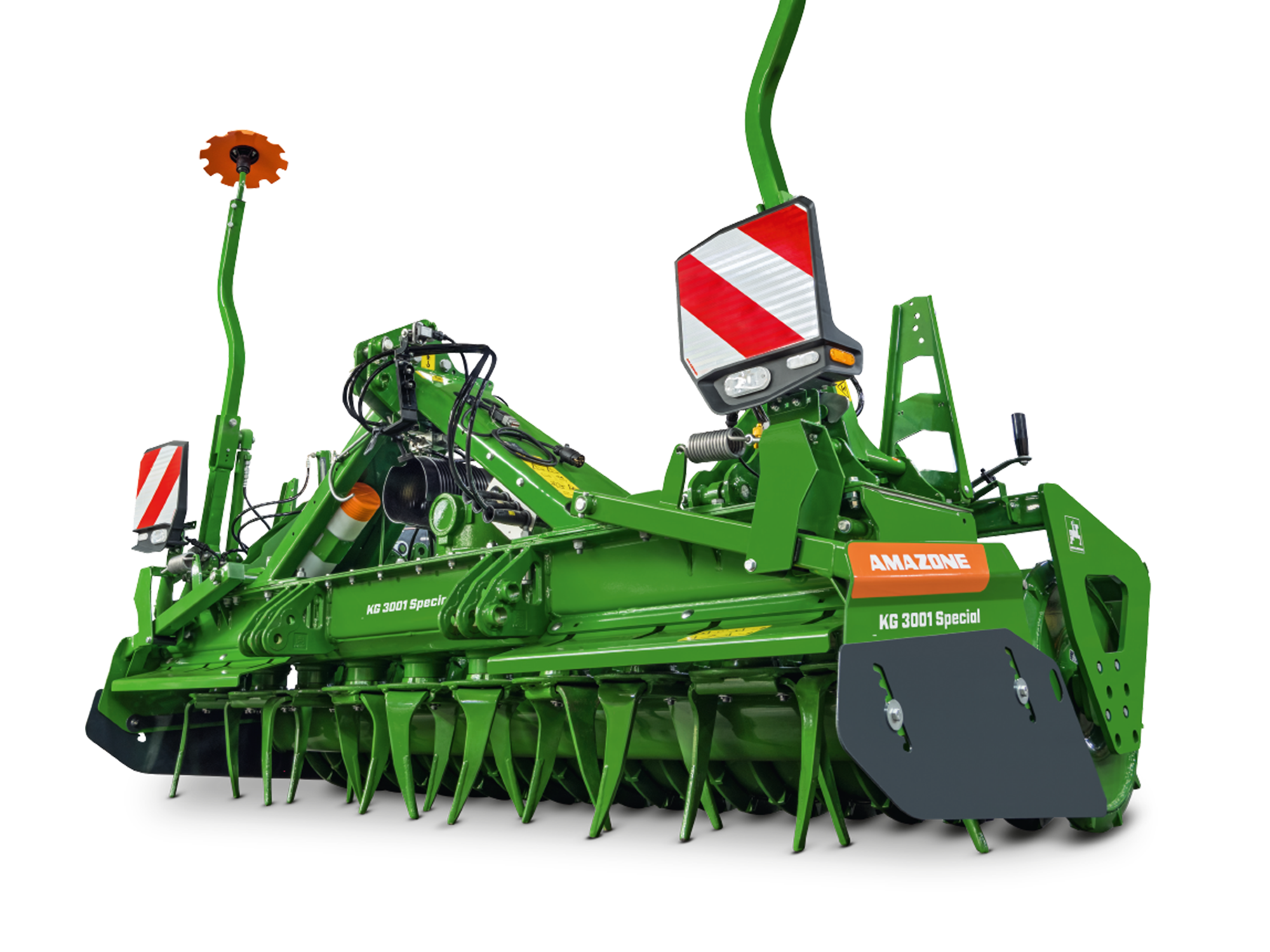

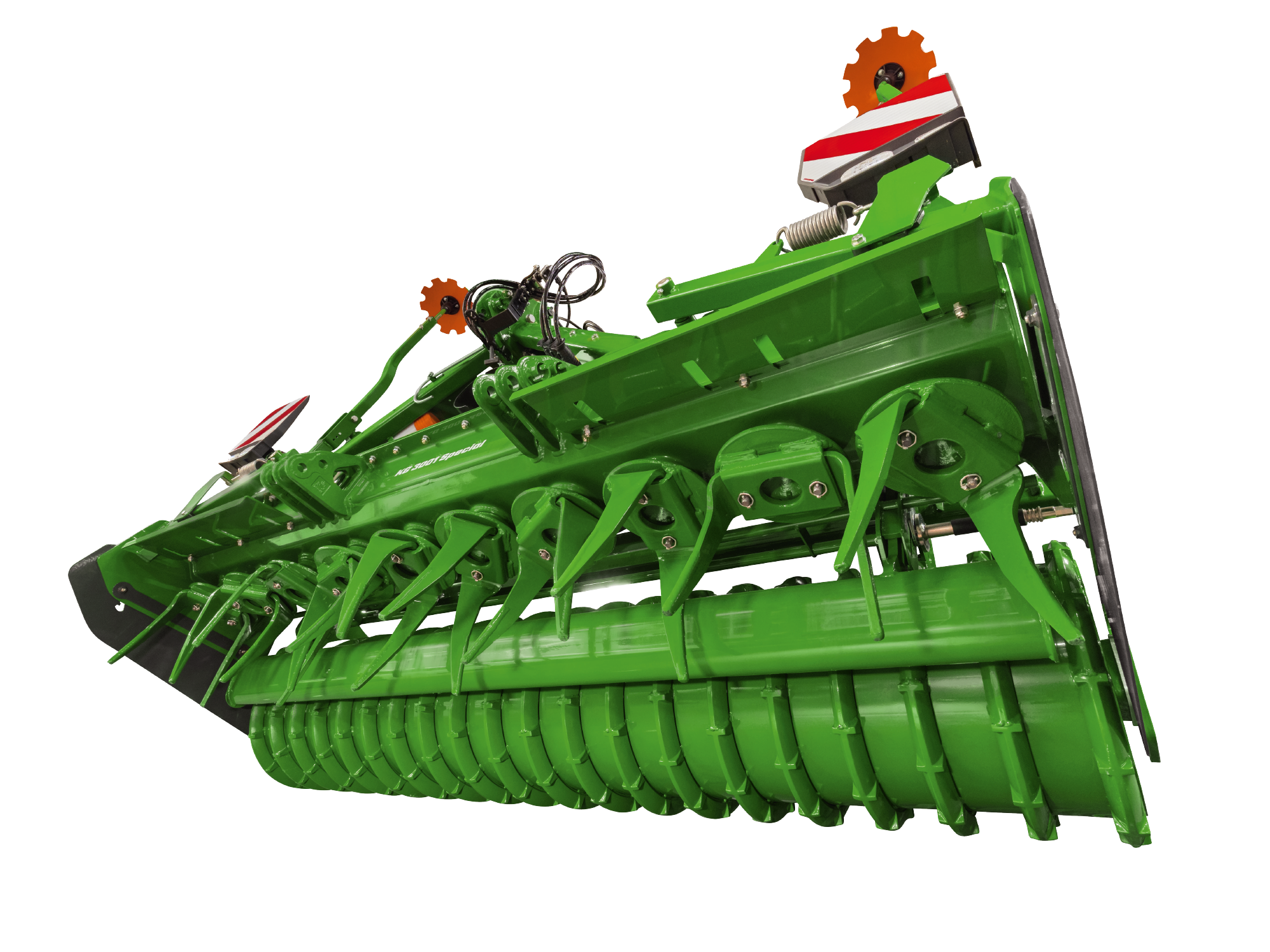

KG Special rotary cultivator – the universal genius

The KG Special rotary cultivators, in working widths of 3 m, 3.5 m and 4 m, are ideally suited for seedbed preparation on heavy soils and for mulch sowing.

KG 3001 Special: for tractors up to 161 kW/220 hp

KG 3501 Special: for tractors up to 161 kW/220 hp

KG 4001 Special: for tractors up to 161 kW/220 hp

KG Super rotary cultivator – the “muscle man”

The KG Super, in 3 m, 3.5 m and 4 m working widths, is equipped with a high capacity gearbox for tractor horsepowers of up to 300 hp. The KG Super has reinforced tines as standard and can be ordered with hydraulic depth adjustment and oil cooler as options.

KG 3001 Super: for tractors up to 220 kW/300 hp

KG 3501 Super: for tractors up to 220 kW/300 hp

KG 4001 Super: for tractors up to 220 kW/300 hp