First-class quality for long-lasting wear parts

The ©plus hardening process – the know-how of heat treatment

As a manufacturer of wearing parts for the soil tillage industry, we can look back on a history spanning decades. Continual advances in materials and production technology as well as our expertise in heat treatment are the basis for achieving the highest possible quality in our wearing parts for ploughs.

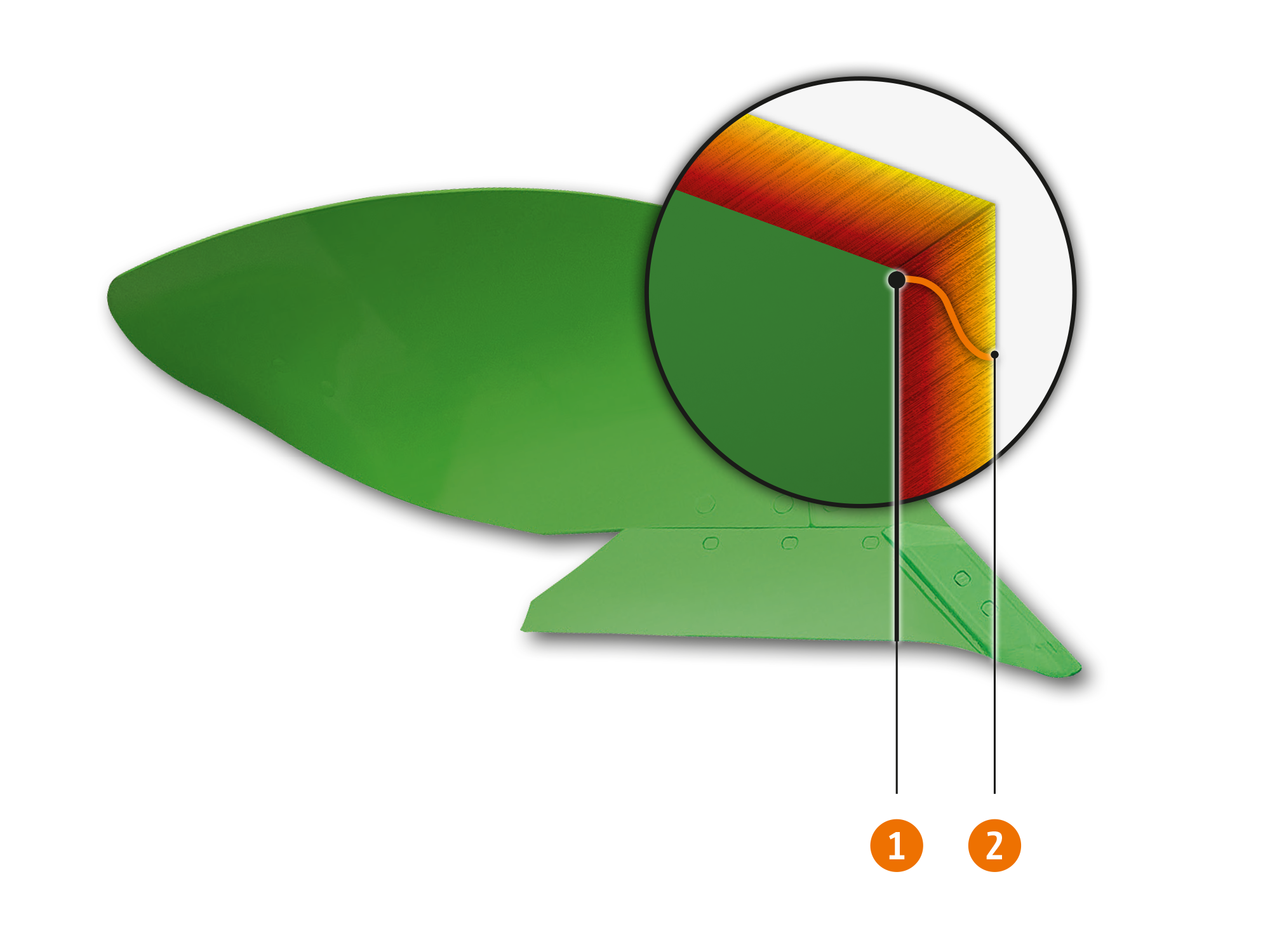

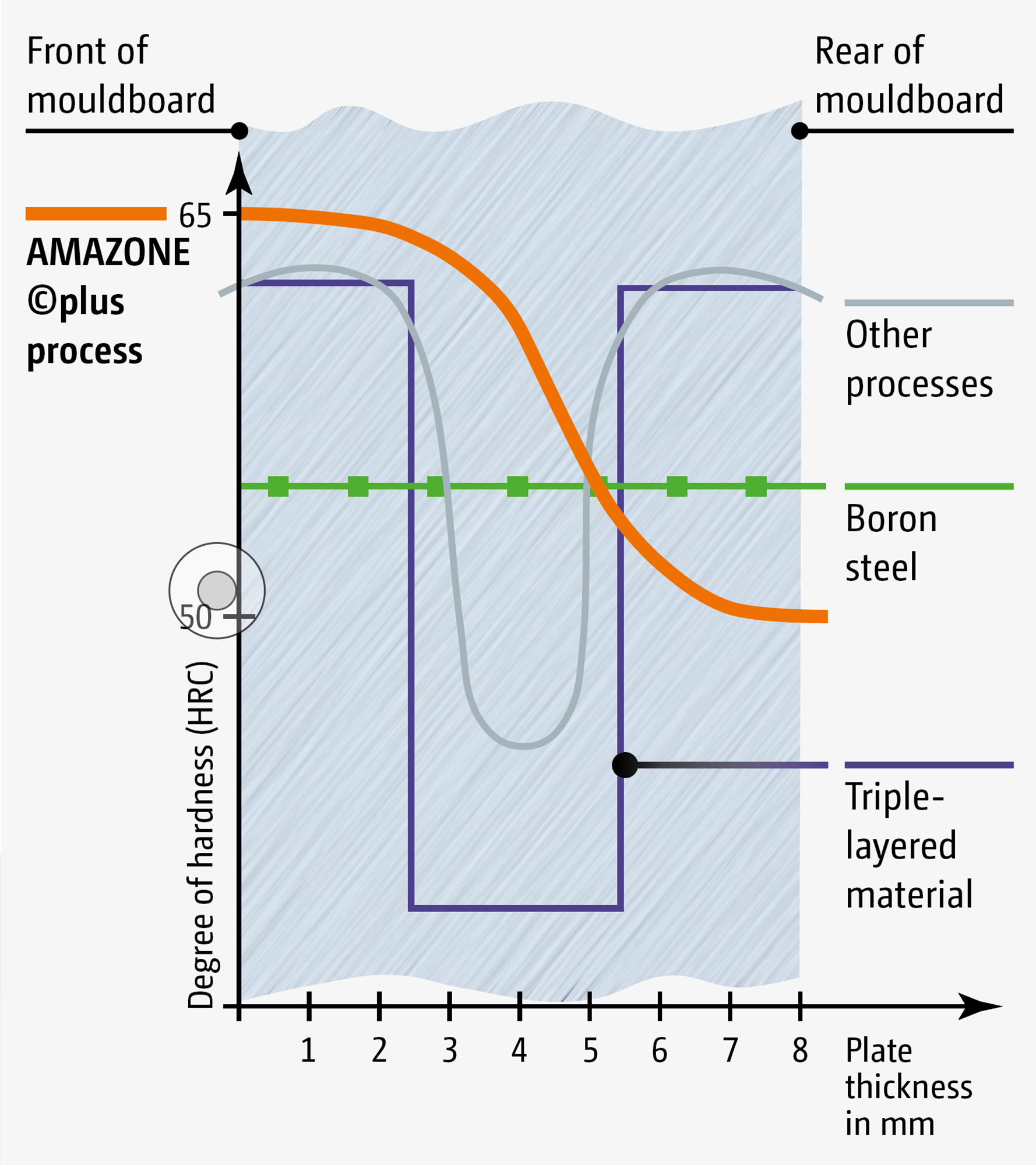

Carbon in its purest form, diamond, is the hardest naturally occurring substance. A hardening process which involves introducing carbon into the steel is used to increase the hardness and durability of ©plus wearing parts. AMAZONE uses a unique hardening process to achieve a very high level of hardness on the front of components, such as the shin, to produce the optimum resistance to wear. The back remains relatively soft but at the same time extremely tough and impact resistant.

Benefits of the ©plus hardening process:

- Longer service life

- High impact resistance

- Less pulling power requirement

- Reduced fuel consumption

- Less sticking to the smoother outer surface

Box section beam made of high-grade steel for a long service life

All the beams on AMAZONE ploughs are produced from a special high-tensile steel. The over-sized wall thickness means that, not only is the whole beam robust, but also all the bolt fixings are extremely strong with this heavy wall thickness also preventing any hole elongation or deformation of the box section around the bolt fixings. A further feature of the ploughs is the design of the plough beam without any weld seams.