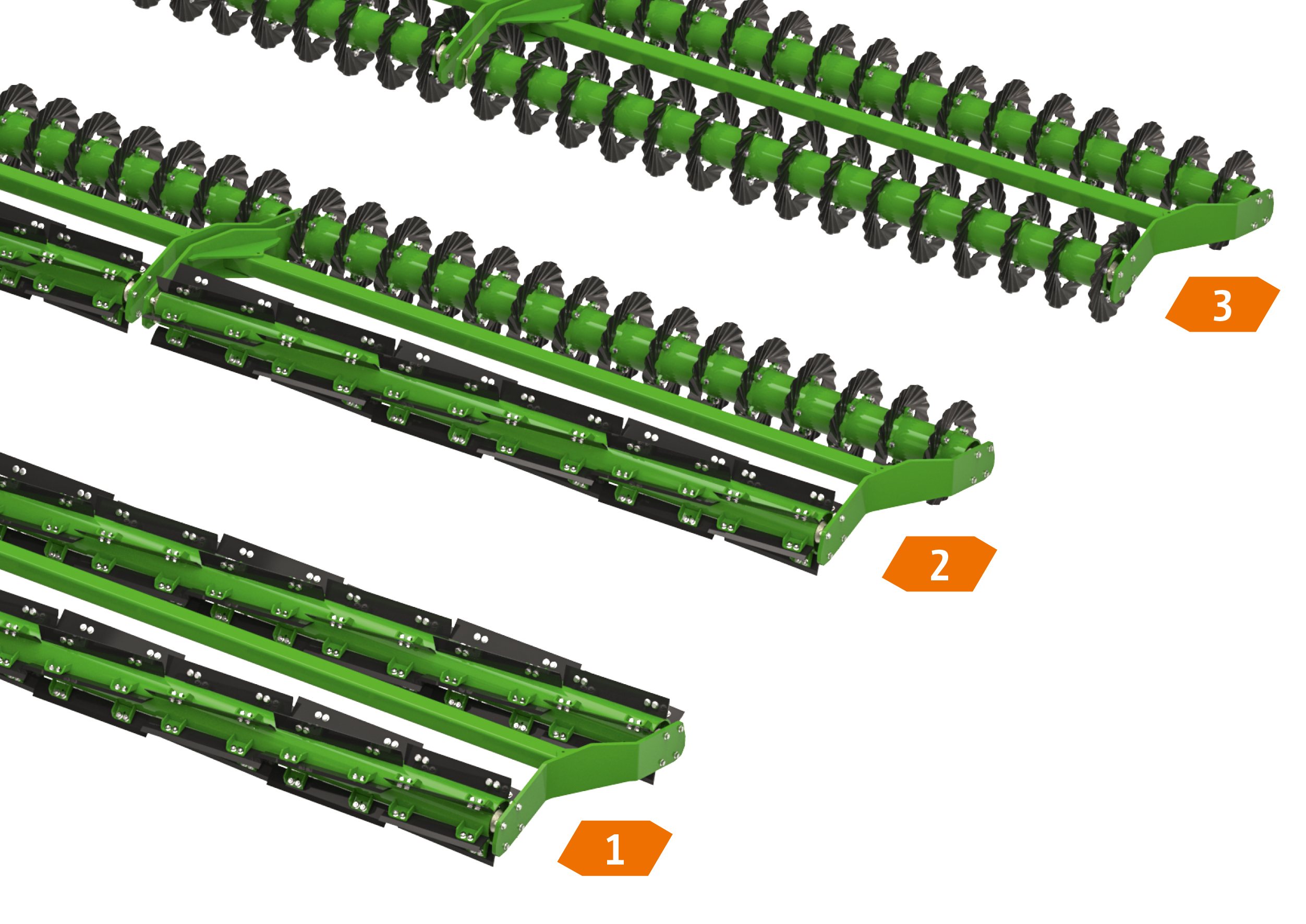

TopCut 12000-2T cutting roller combination

TopCut cutting roller combination with various different tool options for different crops

AMAZONE has developed the TopCut cutting roller combination to meet the increasing requirements for ultra-shallow soil tillage. It consists of up to three consecutive tool segments plus a rear segment that can each be equipped with various different tools to suit the customer’s needs and requirements:

1st. Row: optional leading tools: Knife roller

2nd. to 3rd. Row: Main working segment: Knife roller (MW) or Minimum TillDisc (MTD)

4th. Row: three-row straw harrow or packer roller

For the intensive shredding of long plant residues, such as oil seed rape stalks, sunflower stalks or catch crops, the use of a double-knife roller in the main segment is ideal. The knife rollers intensively shred and bruise the plant residues, significantly accelerating the decomposition process. In addition, despite the shallow cultivation of 0-2 cm, the knife rollers produce enough fine soil to generate the optimum seedbed and so encourage weed seeds and volunteer cereals to germinate. The double-knife roller can also be used for seedbed preparation and the generation of a stale seedbed. The high circumferential speed produces a very good crumbling effect.

To carry out more intensive cultivation with the TopCut, the Minimum TillDisc can be used in combination with the knife roller. One advantage of combining the two tools is that the knife roller cuts crosswise and the Minimum TillDisc cuts lengthwise in the direction of travel. This enables cross-cutting, resulting in an intensive shredding action, especially useful in lodged cereals and maize stubble.

A third combination is to equip the main tool segment with a double Minimum TillDisc. This combination makes it possible to cut into the ground to a depth of up to 3 cm without moving any soil. In spring, for example, this has the advantage of opening up the ground, allowing better aeration and soil warming. This is particularly interesting for direct sowing of spring crops such as cereals or beet. Another advantage is that the two rows of MTD allow lodged cereals to be shredded intensively without moving the soil to any large extent. This makes the TopCut of particular interest to farms that direct sow with tines.

There is also the option of selecting a knife roller as an additional pre-tool. This further intensifies the shredding of plant residues.

Harrowing or reconsolidation

As an option, and to further improve straw distribution after the combine, the heavy three-row harrow can be used behind the main tool segment. In addition to distributing the straw, it also shakes the seeds out of the straw, pods or ears and also produces additional fine soil. This again favours the emergence of weeds. The straw harrow can optionally be ordered as an HD version with a tungsten carbide tip. This increases the service life many times over. The aggressiveness of the harrow can be adjusted hydraulically from the cab whilst on the move.

Another option is to equip the TopCut with a packer roller. The advantage of the roller is that the soil loosened by the knife roller is reconsolidated, thus reducing the drying out of the soil. The DW 600 disc roller is characterised on the one hand by its good reconsolidation and on the other by its particularly good cutting effect. Plant residues, such as maize stubble or catch crops, are split more thoroughly and shredded by the sharp rings on the roller. This, in addition to the main tools, contributes to a faster rotting time.

The KWM 600, for example, is characterised by its crumbling effect, especially in a classic seedbed preparation situation.

It is also ideal for creating a stale seedbed. This causes problem weeds, such as black grass and loose silky bent, to germinate before the actual sowing time meaning that they can be controlled mechanically by the TopCut in a second pass.

Conclusion:

The TopCut 12000-2T cutting roller combination is the right choice for every farm, thanks to the wide range of tool combinations and rear element. This means that the TopCut can be integrated effectively into a classic mulch sowing scenario, sowing after the plough or direct seeding. Thanks to its wide working width of 12.1 m and high working speeds of up to 20 km/h, enormous daily work rates can be achieved, and this is particularly favourable economically, having a very low fuel consumption of approx. just 2.5 l/ha. In addition to the large areas covered, the TopCut also impresses with its resistance to wear and tear. Thanks to the reversible knives on the knife roller, not only can the service life be doubled, but the wear costs can also be minimised.

- Perfect shredding in rape, sunflowers, maize stubbles and in catch crops

- Optimum shredding for an accelerated decomposition process

- Ultra-shallow soil tillage with high proportion of fine soil for perfect germination conditions, even on cereal stubble

- Improved straw distribution and fine soil generation with the harrow

- Optimum reconsolidation for reliable emergence of weeds and volunteer crops with the rear packer roller

- Markedly reduced evaporation compared with other processes

- Very high work rates with low fuel consumption

- Reduced wear costs due to the reversible blades => double the service life

Gallery