Pulse width frequency modulation: AmaXact

Application technology at a new level

Optimising the application of plant protection agents is essential for effective plant protection. Nozzle technology plays a decisive role here. The requirements for the nozzle system can vary depending on the operating conditions. AMAZONE already offers customers a wide range of nozzle bodies – from part-width section control with single nozzle bodies to the electric AmaSelect nozzle body with automatic nozzle changeover.

With AmaXact, AMAZONE is now introducing a nozzle body with pulse width frequency modulation. This is particularly suitable for farms with medium to large field sizes as well as for part-area, site-specific control and spot spraying.

Pulse width frequency modulation

With pulse width frequency modulation (PWFM) technology, the valve in the nozzle body opens and closes several times per second, whilst the opening times (pulse widths) can be adjusted as required. While the application rate is directly dependent on the spraying pressure in conventional nozzle bodies, the PWFM system enables the rate to be regulated via the on/off times, thereby providing a certain degree of independence from the spraying pressure.

The ability to control each PWFM valve individually offers a number of advantages for the application. In addition to individual nozzle control for minimal overlapping, continuous curve compensation is now possible. The driver also has the option of varying the forward speed within a certain range without changing the droplet size. This results in a gain in terms of performance and consistency of application quality.

Another important advantage can be seen in the area of precision agriculture. The individual control of the valves enables precise part-area, site-specific application, even within the boom width. Due to the high switching speed of the valves, the system is also ideal for spot application, in order to achieve maximum savings with small spot areas.

In addition to high switching speeds, particularly fast and precise pressure control is essential for precise spot application in order to maintain the exact application rate, including in the spots. AMAZONE has developed the DynamicFlow hydraulic pressure regulator specifically for the AmaXact system. It enables extremely fast pressure control, thereby optimising application accuracy in both spot and full width applications.

Intuitive operating concept

AmaXact is an in-house development from AMAZONE. As a result, the system not only meets AMAZONE's own highest quality standards, but also offers the customer complete integration in the software for ease of use and clear operator guidance. The driver simply enters the desired droplet size to obtain a speed range within which the sprayer can be then driven. The driver also has the option of reacting flexibly to particular crop situations by manually adjusting the application rate in certain areas.

Thanks to full system integration, it will be possible to digitally connect to the AmaConnect cloud-based data platform in the future. By using real-time data and digital assistance systems, the intelligent networking of the sprayer will enable the foundation to be laid for smart functions with a focus on decision support, automation, process monitoring and quality assurance.

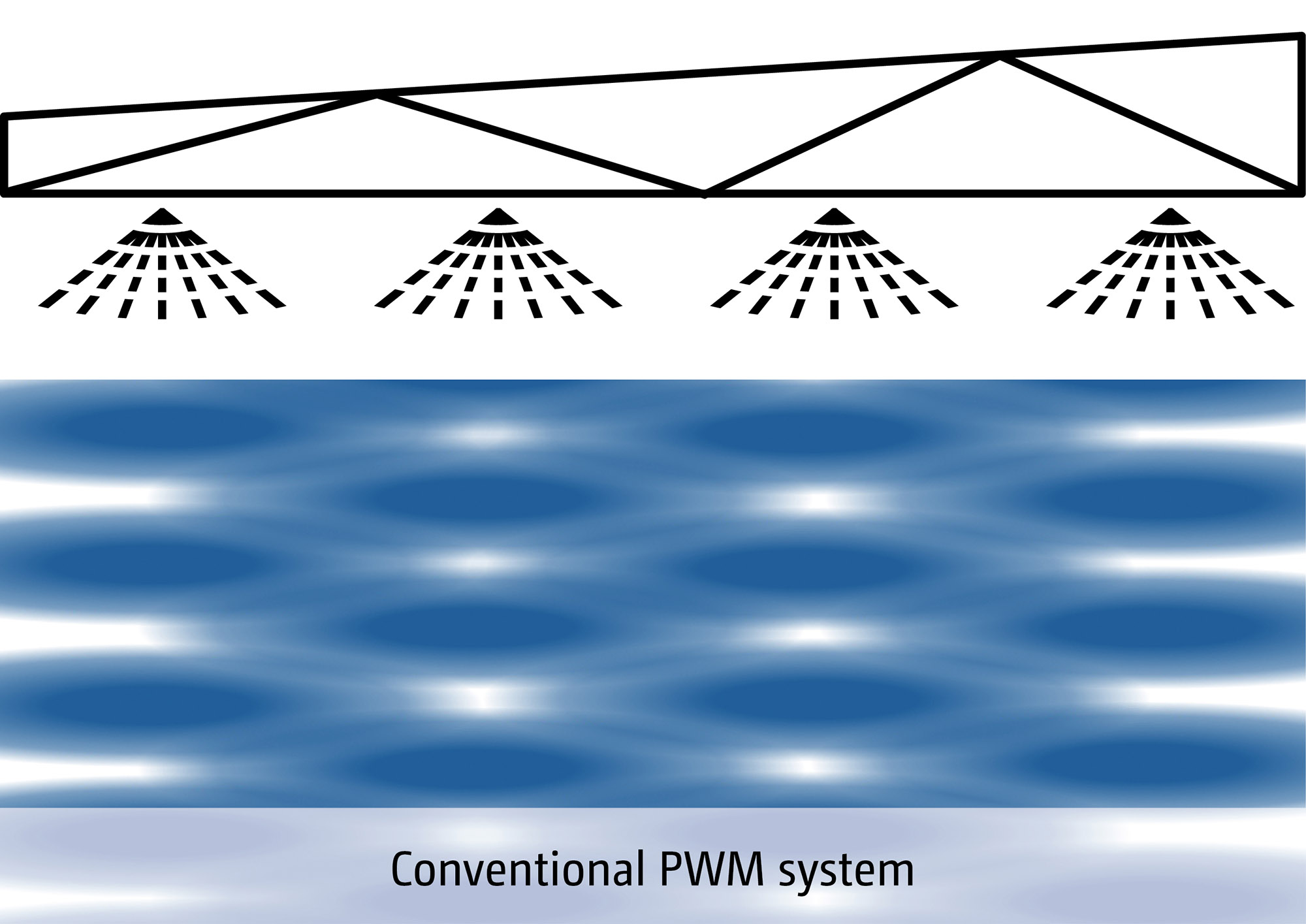

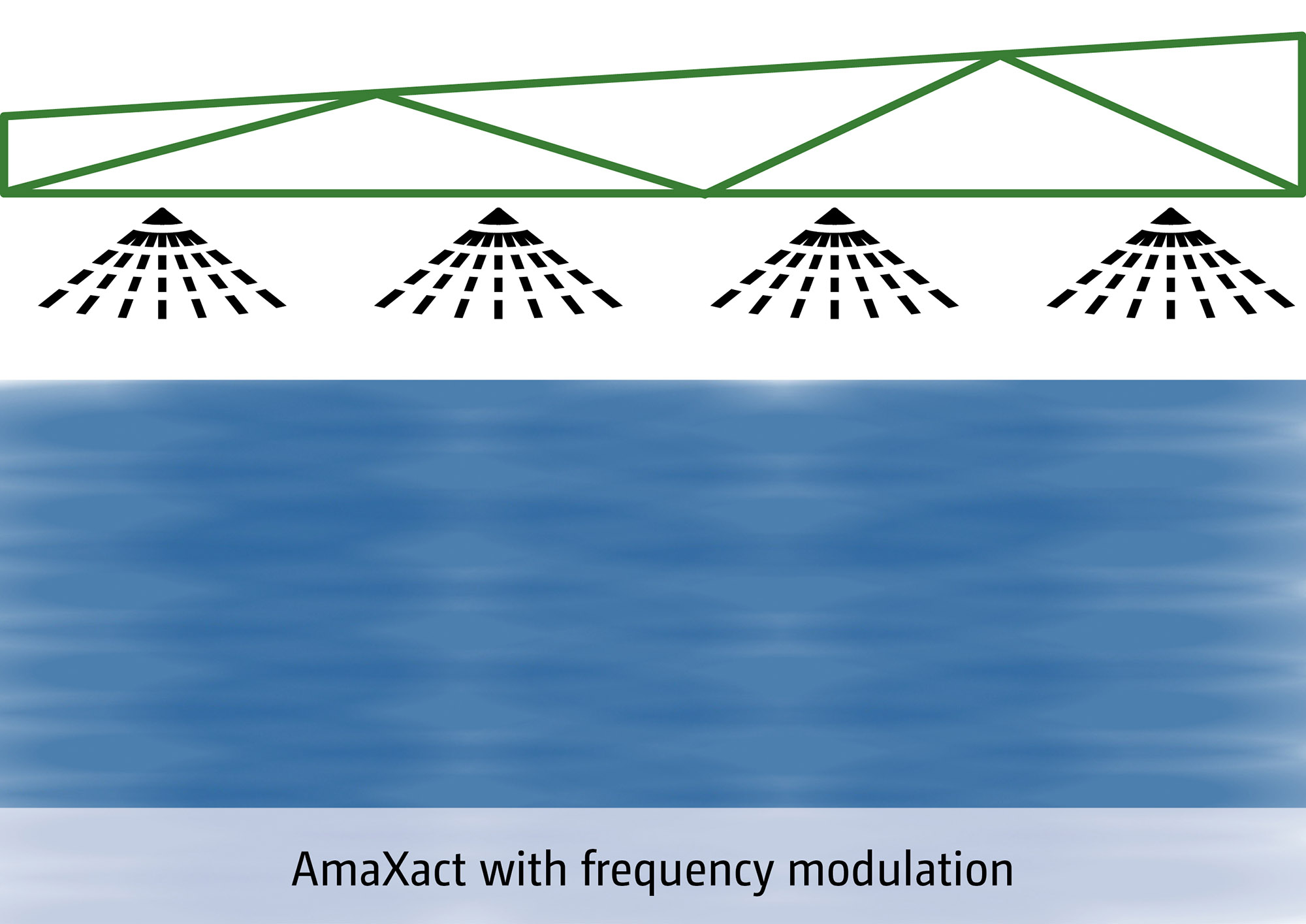

Better application quality using frequency modulation

AMAZONE goes one step further with AmaXact to solve the challenges of conventional pulse width modulation (PWM) systems. In PWFM, the number of switching cycles is controlled in addition to the opening time of the valves. This generates a decisive advantage: Conventional PWM systems can lead to poor longitudinal distribution in certain driving situations, primarily in connection with high forward speeds, which can then even be seen in the crops. This happens due to the distance that the boom has travelled whilst the nozzle is closed. AmaXact automatically increases the switching frequency in these situations to avoid inaccurate distribution.

Pressure control: larger working range and minimised wear

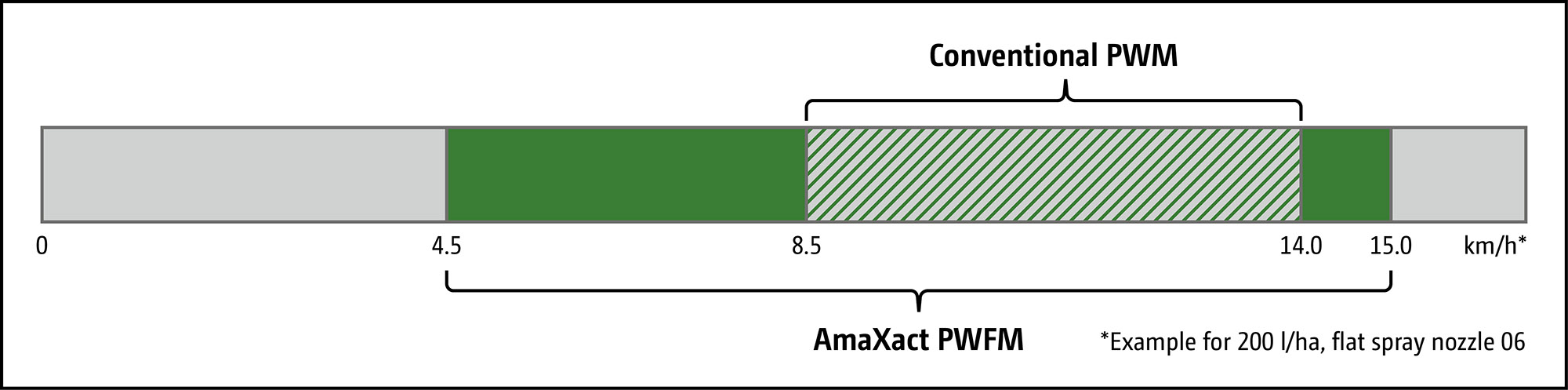

Compared to the automatic switching to different nozzles, PWM offers the advantage that it works continuously with just one nozzle and always delivers the same application quality within a certain working range. At the same time, the disadvantage of conventional PWM technology may mean that this working range is smaller, as the application quality decreases if the opening times are too short.

AmaXact also offers a solution for this by using PWFM technology. To increase the working range, a pressure range in which the nozzle generates the desired droplet size can be entered instead of a single pressure value. AmaXact automatically regulates pressure, frequency and opening times in such a way that the application quality remains consistently high and, at the same time, an up to 87 % larger working range in terms of speed and application rate is possible. This principle is also utilised in the CurveControl Flex curve compensation, where the system achieves the desired application rate, even in tight curves and at varying forward speeds, thanks to the pressure control.

The pressure control is also used to reduce switching cycles and thus extend the service life of the valves. At high duty cycles, the system automatically switches from pulses to continuous nozzle opening. This significantly reduces the number of switching cycles, depending on the driving situation. During this time, the quantity is regulated by the pressure control within the predefined pressure range. The application quality remains consistent, whilst wear is minimised.

- Precise small part-area, site-specific spot spraying

- Extremely simple and comfortable operating concept

- Long service life thanks to intelligent wear minimisation

- Perfect application quality even in border areas

- Wide speed and volume range with just one nozzle for maximum flexibility and performance

Gallery