Precea precision air seeder perfected

Up to 30 % saving on fertiliser with the combination of triangular seed placement, FertiSpot, Section Control and CurveControl

The expansion of the red zones concerning fertiliser application and increasing social pressure are leading to ever-stricter fertiliser regulations, and thus to further restrictions of fertiliser rates. Higher fertiliser and input costs are further increasing farmers' demands for more efficient and resource-saving machinery.

Saving fertiliser exactly on the row

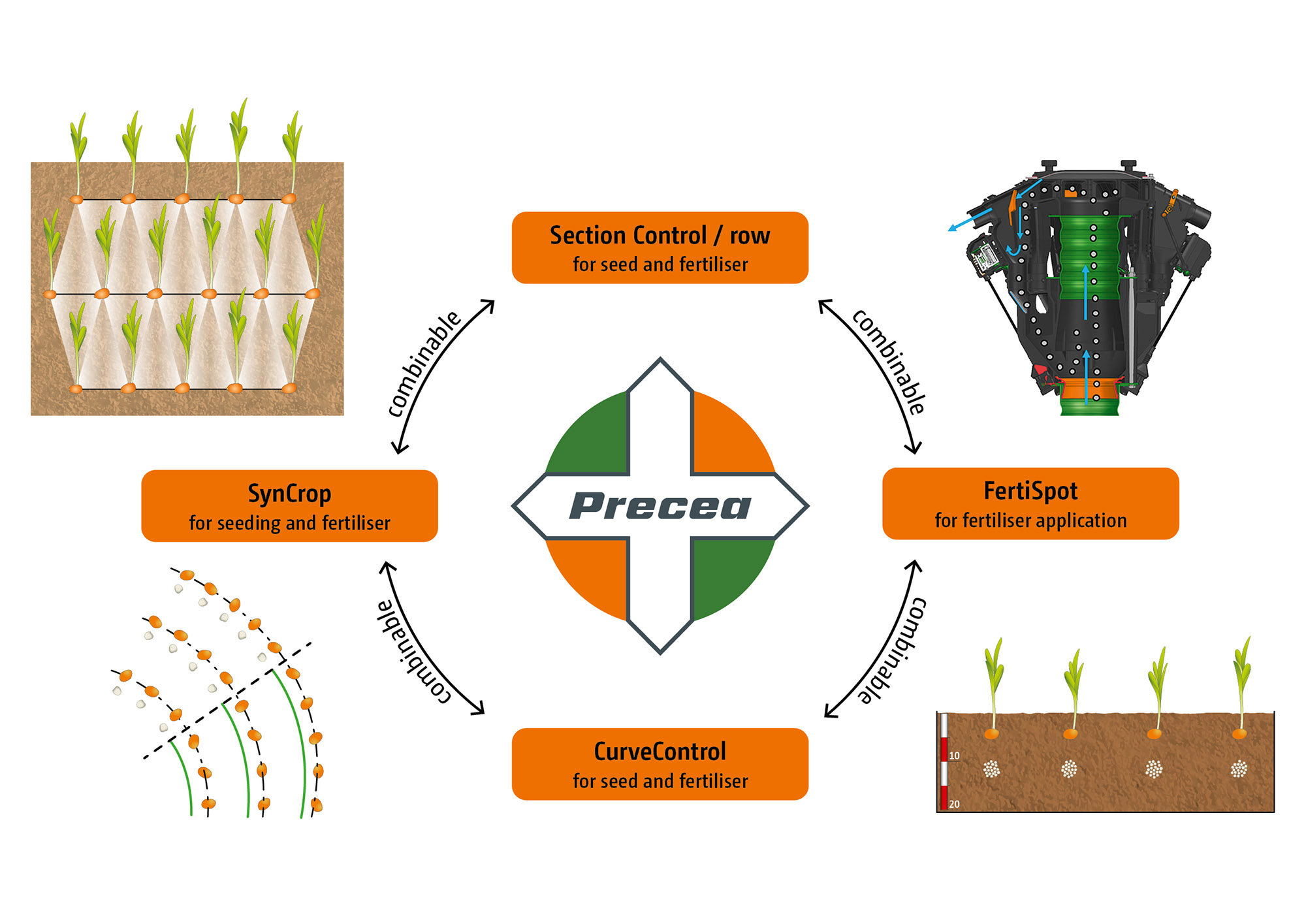

Various innovative solutions from AMAZONE take precision seeding with fertiliser application to a new level - individually or combined synergistically.

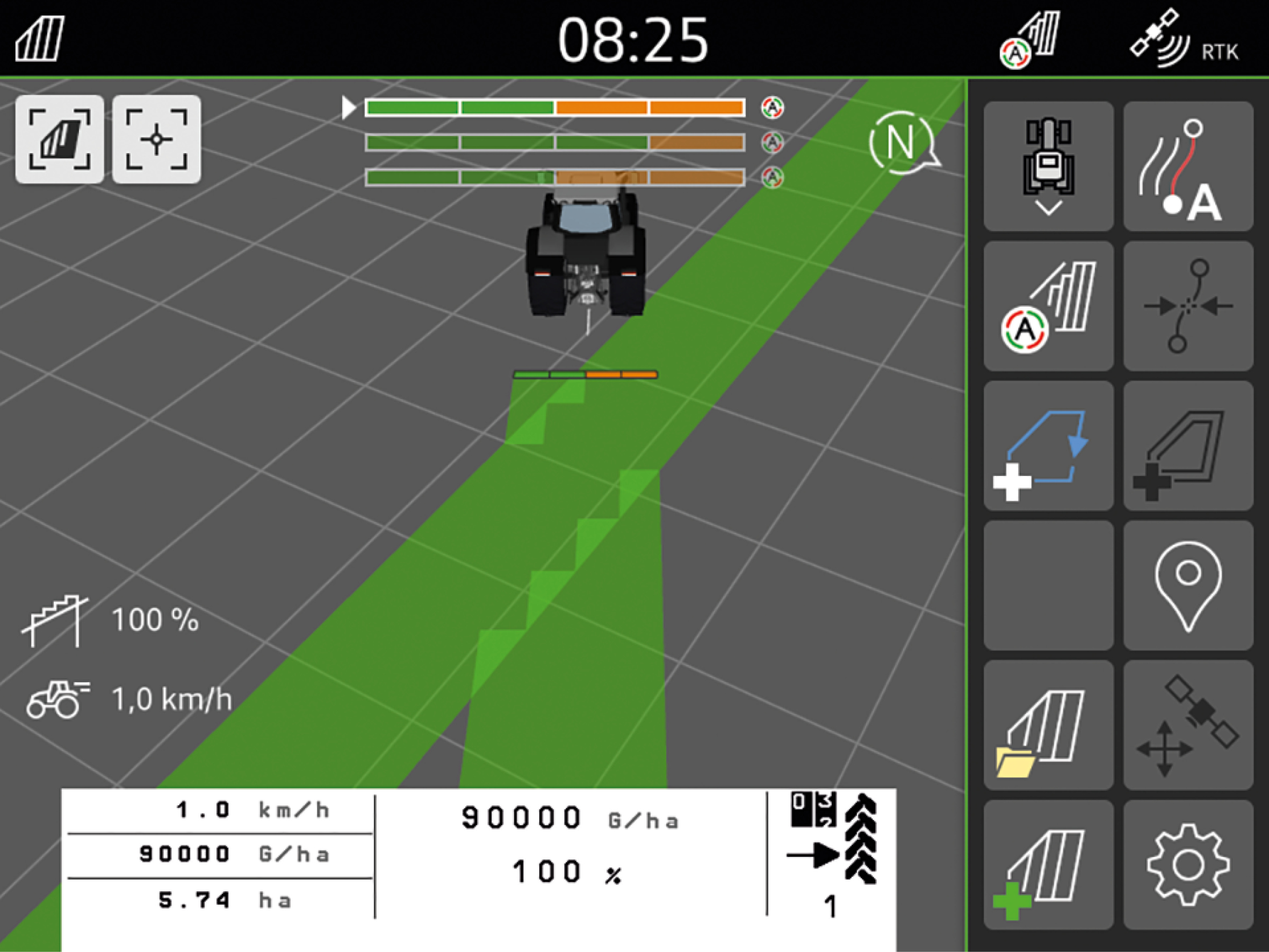

Fertilisers can be applied very effectively at the desired rate within the framework of legal regulations. For example, fertiliser application on the Precea can be automatically switched off in the outer rows alongside bodies of water or on angled headlands

Section Control

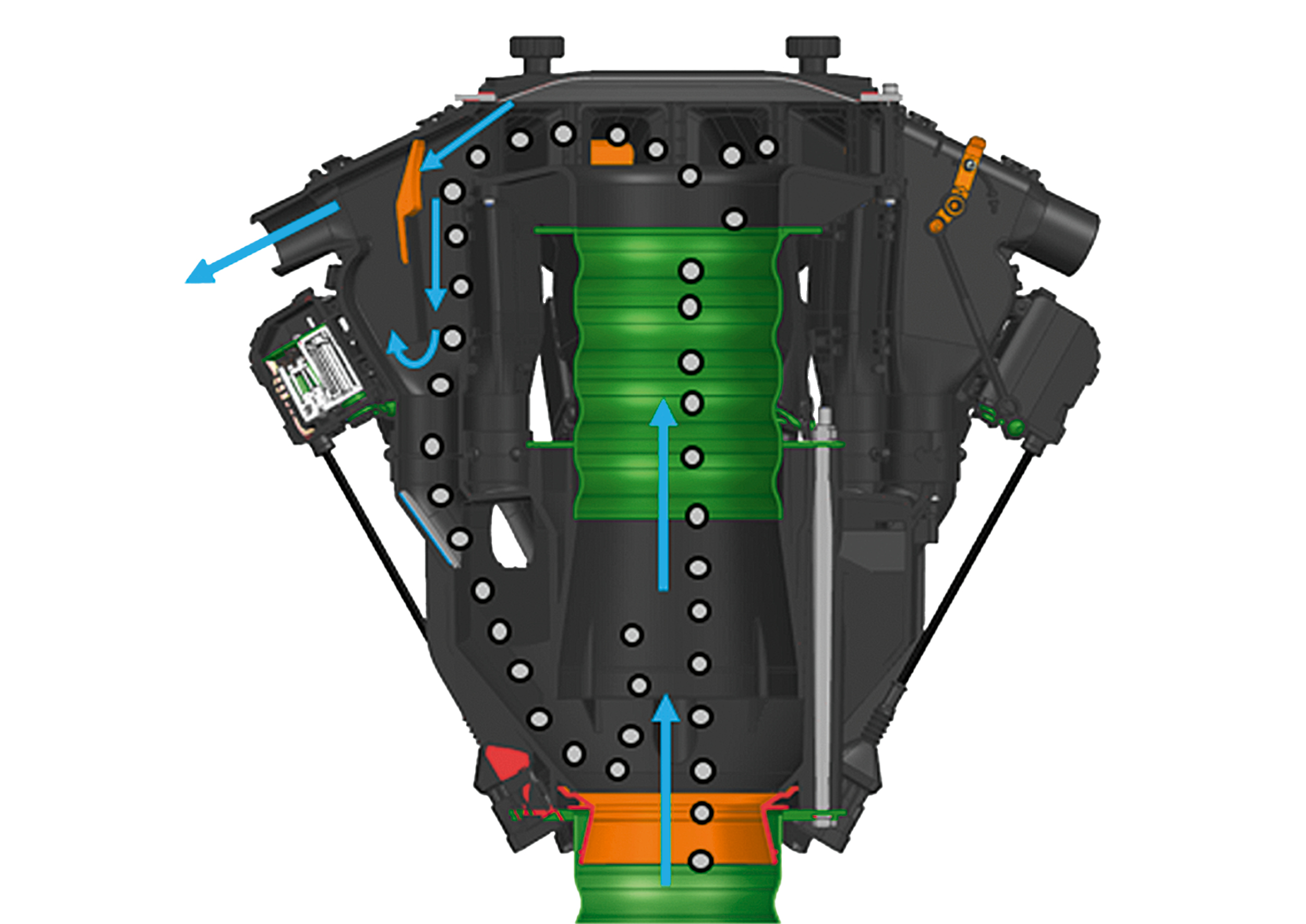

The Precea precision air seeders stop applying fertiliser via the single row control with Section Control. With pneumatic conveying, the distributor head switches off the fertiliser application on wedge shaped fields and at the headland up to the last row, without any loss of conveying capacity.

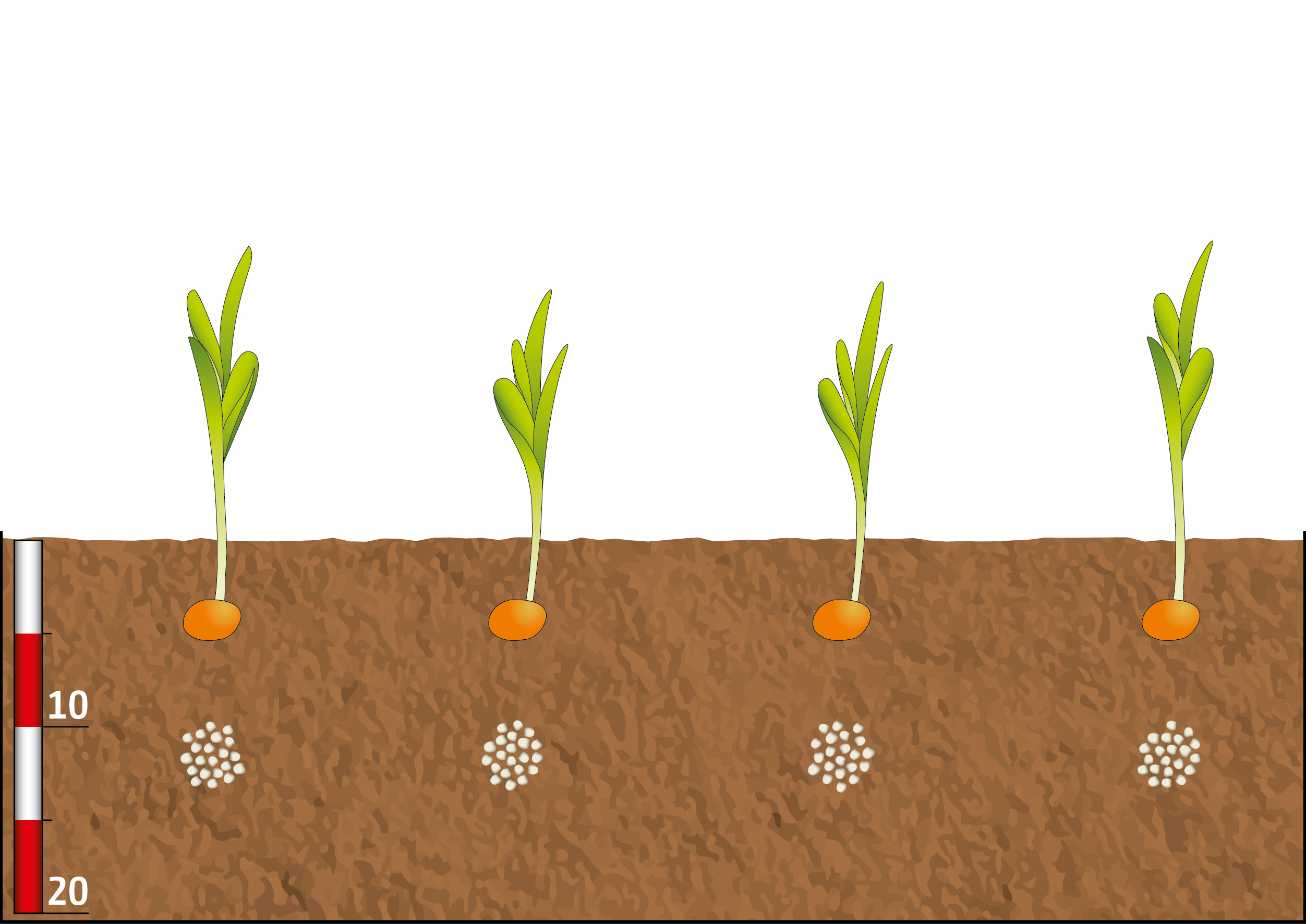

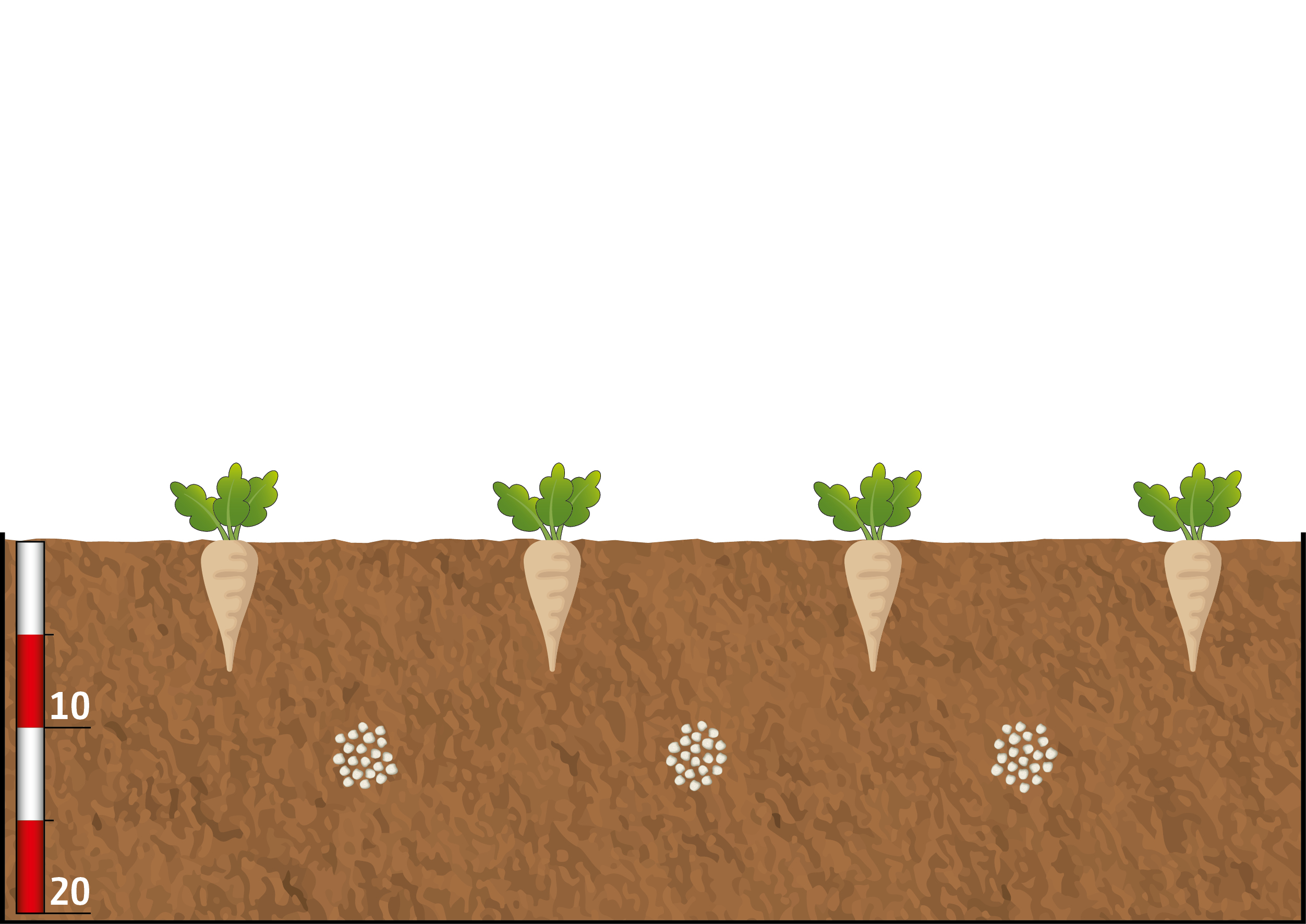

FertiSpot

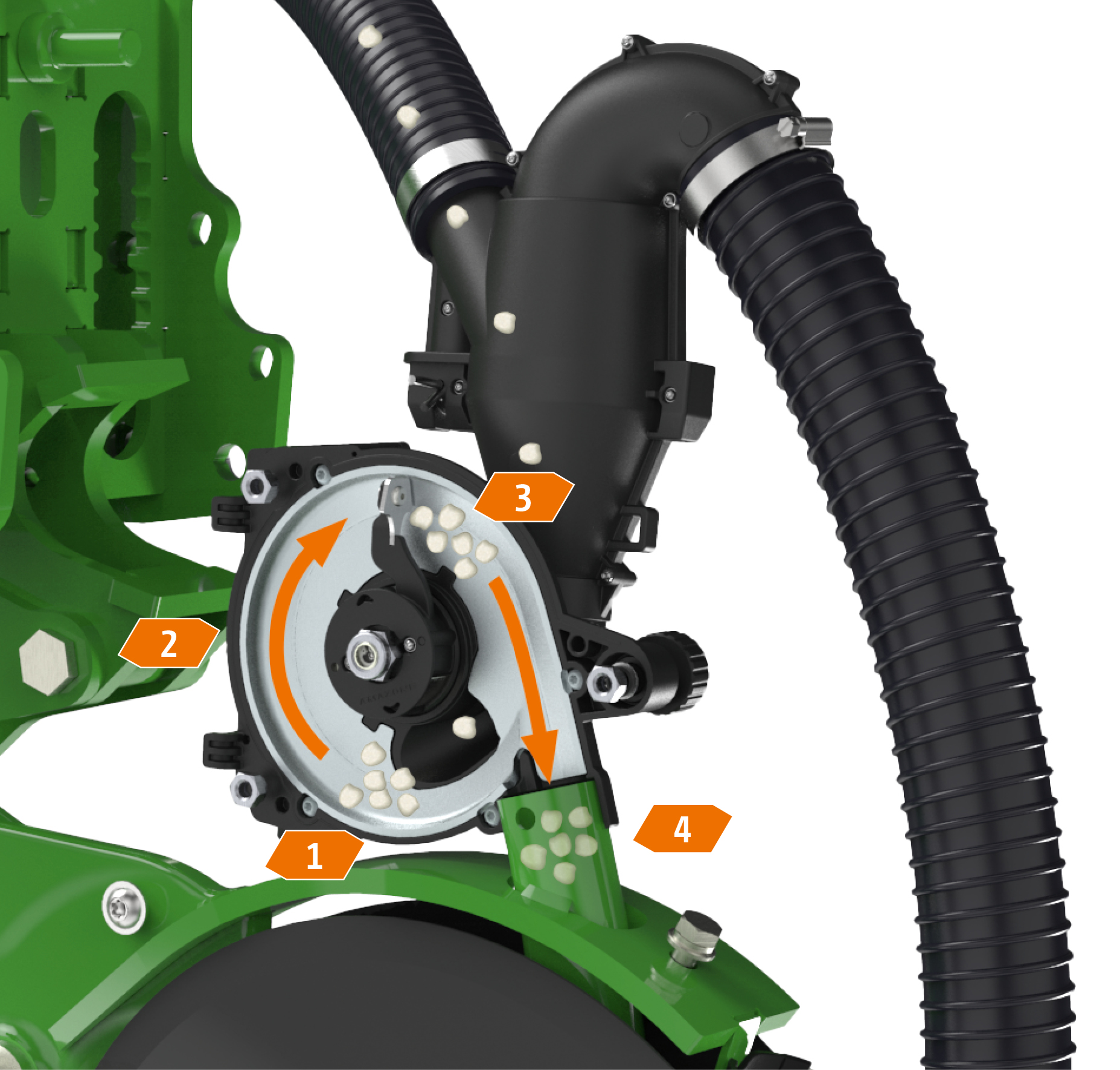

The next step is to fertilise the individual plants as required. The mineral fertiliser is transferred from the fertiliser metering system to the FertiSpot fertiliser portioning unit. The fertiliser flow, which continuously enters the portioning unit, is gathered together by a high-speed portioning rotor. It leaves the unit as a portion and is delivered to the fertiliser coulter. The control of the portioning unit and delivery of the seed are synchronised. Control is provided via the Precea ISOBUS control system.

A new feature is the option of placing the spot between two deposited seeds, depending on the application, in order to protect the fine roots of sensitive crops such as sugar beet. The tractor driver can enter the precise intended location of the spot under the seed or offset between two seeds using the ISOBUS control system.

The concentrated fertiliser dose can also be selected as MultiSpot for crops with a high number of plants per hectare. Compared to band application, the concentration of nutrients in the soil is lower due to the increased concentration in the fertiliser doses. This improves the long-term absorption of nutrients.

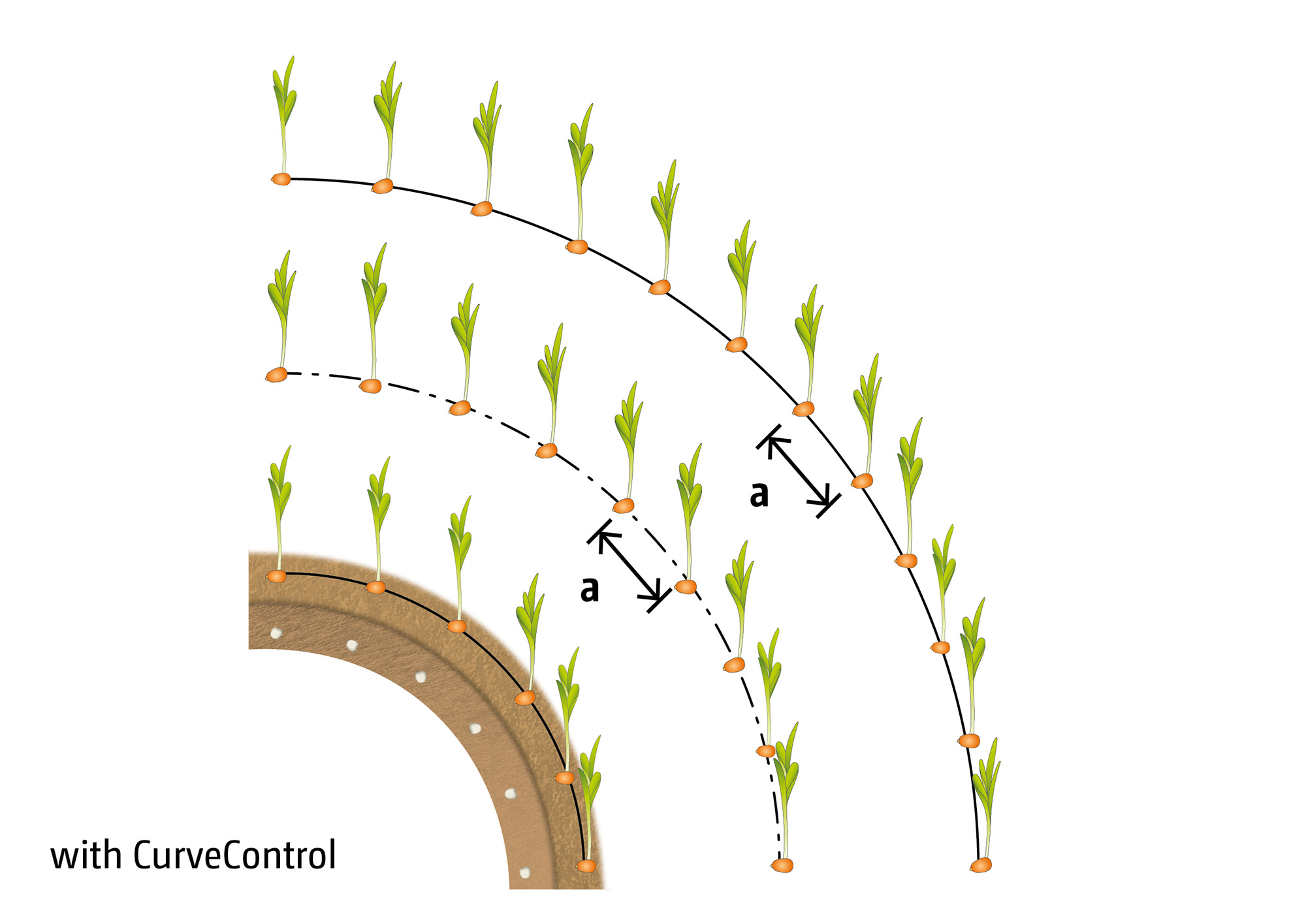

CurveControl

The CurveControl function is used to distribute seed and fertiliser as precisely as possible, even when cornering. This means that the fertiliser is distributed differently in the outer area of the curve than in the inner area, but always exactly according to the seeds sown. This avoids underdosing and overdosing of the fertiliser and leads to uniform crops.

CurveControl for seed and fertiliser

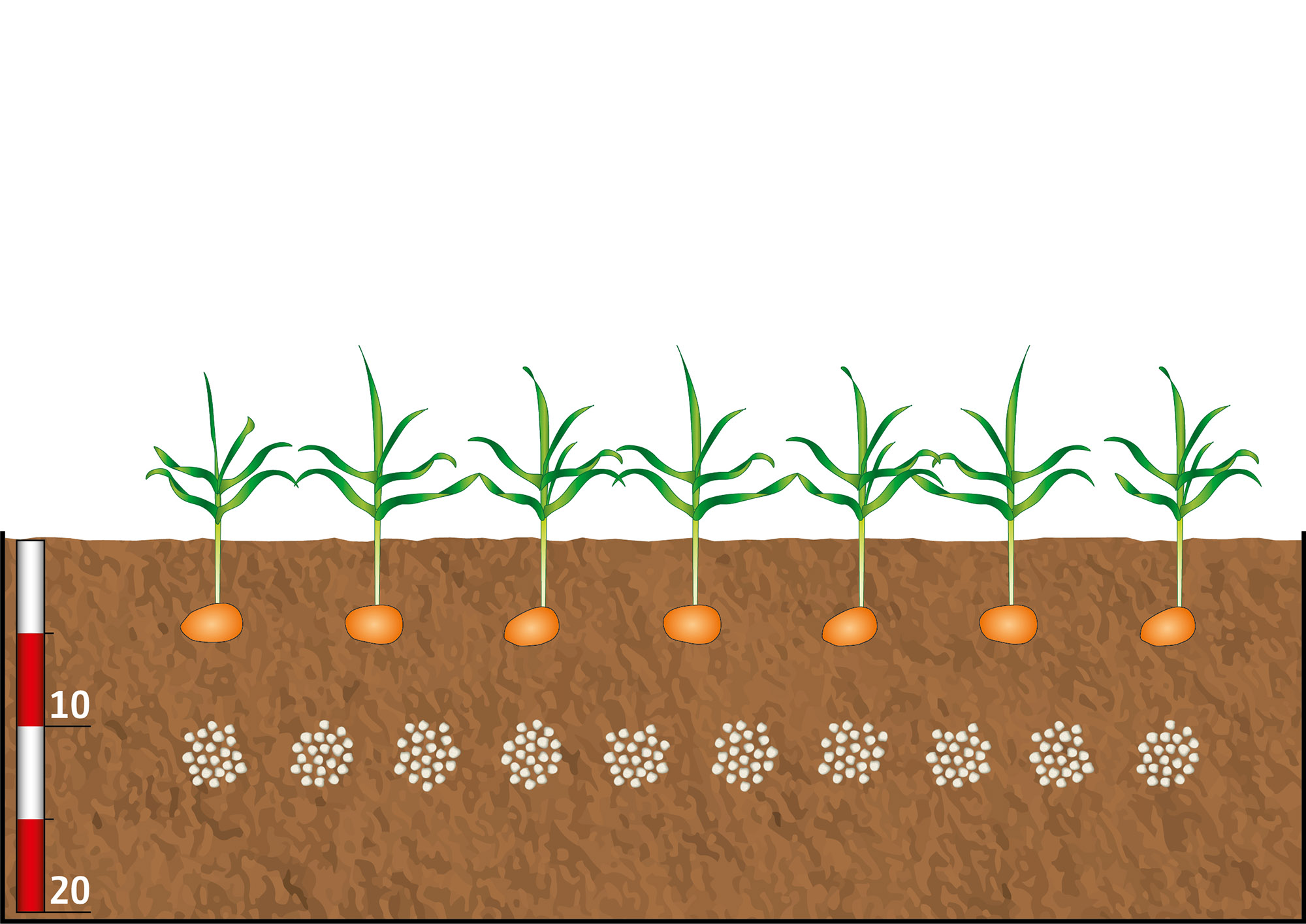

From spring 2026, there will be a new software solution available, SynCrop that enables the synchronised sowing of seed and fertiliser across the rows in a triangular or block formation.

Thanks to the cross-row synchronisation of the sowing units, seed and fertiliser can be sown in a triangular formation. This maximises the distance between the plants and optimises plant distribution. The availability of nutrients, daylight, water and air is improved for every plant.

The improved nutrient availability can lead to faster leaf growth and faster row closure. The bare soil in the gap is covered more quickly and weed growth is suppressed more efficiently. Maize plants at an early growth stage, in particular, can benefit to a great extent.

The sunlight is optimally utilised by arranging the plants in a triangular formation, while soil erosion on hilly terrain can be reduced.

Combined for a new level of precision

The combination of the FertiSpot fertiliser portioning system, the single row control for fertiliser application via Section Control, the precise plant distribution in the row with CurveControl plus the arrangement of the plants in a triangular formation represents a new level of precision when precision sowing.

The intelligent combination of individual functions enables fertiliser savings of up to30 % in total. The exact amount of fertiliser applied to the plant also secures the yield potential and optimises crop management by ensuring the most uniform plant development possible.

Due to the high fertiliser savings of up to 30 %, the system is an added value from an economic point of view. Saving on fertiliser also reduces logistics costs since less fertiliser needs to be moved around the farm. This also makes work considerably easier since fewer filling operations are required per hectare.

In view of the costly, energy-intensive breakdown of nutrients such as phosphate, the reduced fertiliser application has less impact on the environment. The more efficient use of these raw materials also ensures additional ground water protection.

For new Precea orders, the systems Section Control with single-row switching, FertiSpot with up to 12 rows, CurveControl and the triangular placement software can be ordered. Models from 2025 year of manufacture onwards are already prepared for retrofitting all these systems.

- Reduction in inputs: better precision on the headland or in wedge-shaped areas prevents over-seeding - fertiliser and seed are saved and input costs are reduced.

- Efficient fertiliser supply: precise metering and pinpoint delivery of the fertiliser to each seed prevents over-application.

- Cost-saving: fertiliser savings of up to 30 % can be achieved with the combination of triangular seed placement, FertiSpot, Section Control and CurveControl.

Gallery