Pantera 7004 now even more flexible!

New W chassis, DirectInject and Trimble steering system

The Pantera 7004 self-propelled crop protection sprayer presented at this latest Agritechnica exhibition is characterised not only by its high output but also by its outstanding handling characteristics, which are achieved thanks to the special chassis concept. Customers also appreciate the intuitive and comfortable operation of the sprayer.

With the newly-available options of the W-chassis and Trimble steering system, the sprayer can now be even better customised to individual customer's requirements. Thanks to the optional DirectInject direct injection system, the use of crop protection agents can also be made even more efficient and flexible.

W Chassis

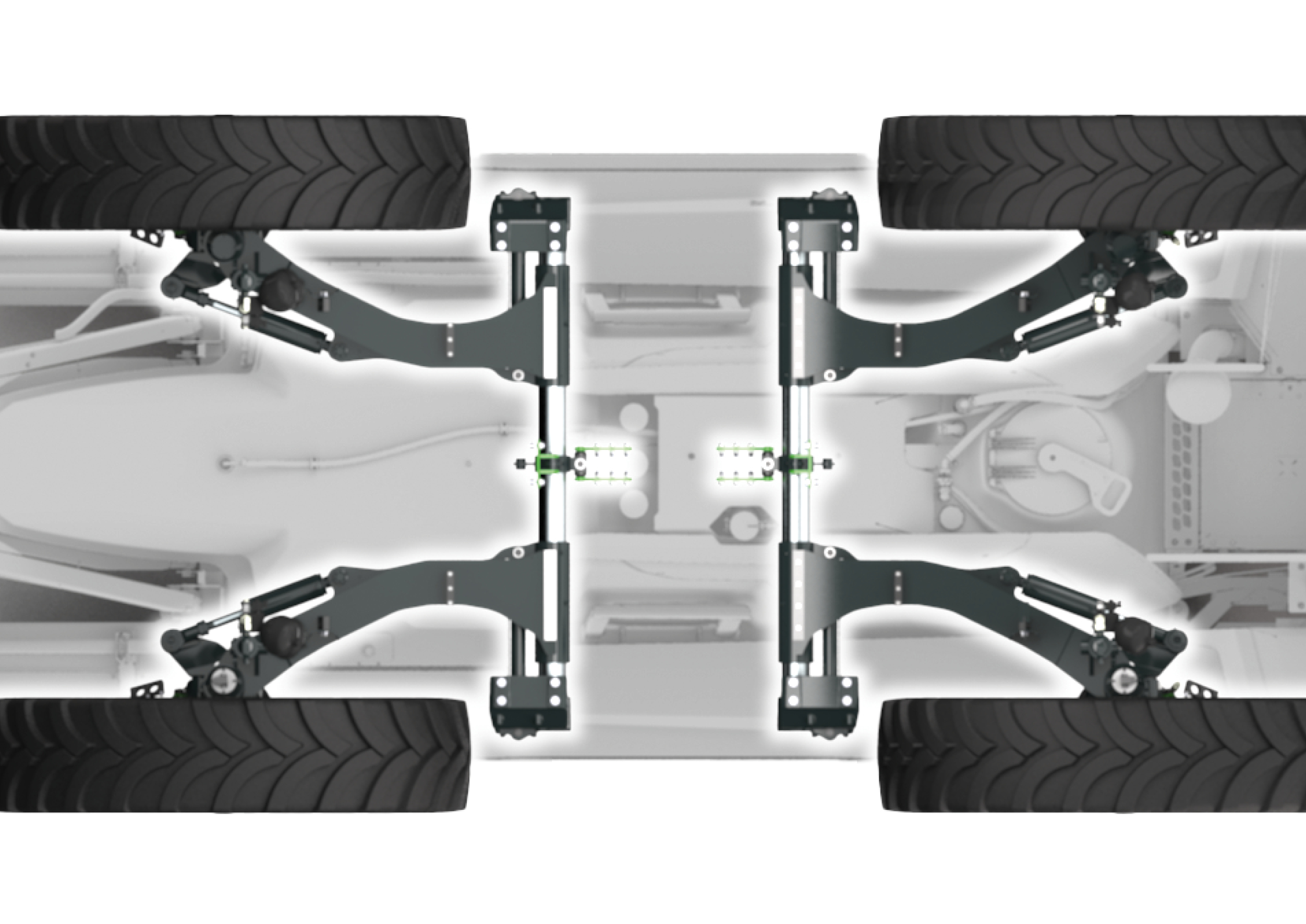

In addition to the standard chassis, having a track width of 2.00 m to 2.75 m, which is infinitely adjustable hydraulically as standard, the Pantera 7004 W offers track widths of 2.25 m to 3.00 m.

Thanks to the wide scope of adjustment, two important track widths are covered. Firstly, the increasingly common track width of 2.25 m for cereals, maize and potatoes with tramlines. Secondly, the 3.00 m track width for potatoes with no tramlines, specialist crops and, for instance, arable farming under a Controlled Traffic Farming scenario.

The Pantera's unique chassis technology offers extraordinary advantages. The design of the independent trailing arm suspension enables a considerable weight reduction compared to a conventional independent suspension system and is also particularly easy to maintain due to the low number of pivot points. The hydro-pneumatic suspension is adaptive, meaning that the characteristics of the running gear are tailored to suit the driving situation. This intelligent control system enables optimum driving stability and maximum driver comfort.

In addition to the ground-protecting function of off-track driving, where the ground is only run on once, the integrated slope levelling function is another special highlight. The sprayer is automatically kept level, up to a specific slope inclination. This feature, in combination with the low centre of gravity of the implement and the hydro-pneumatic running gear, provides extremely high levels of slope stability.

DirectInject direct feed system

DirectInject has already been used hundreds of times on the market with the UX 01 trailed sprayer range. Users appreciate the particularly high level of flexibility in crop protection applications, combined with the system's very simple operation. The entire Pantera product range can now also be equipped with DirectInject in order to deliver individual crop protection products flexibly, quickly and as required.

An additional product can be added to the spray agent circuit during application at the touch of a button. The special feature of DirectInject is the short reaction distance of only around 30 to 50 metres. This is essential for the flexible treatment of weed patches in particular. Furthermore, the system facilitates flexible plant protection measures in many everyday situations, for instance, the separate treatment around field boundaries, the metering of additional products on individual fields with special requirements as well as the variable application rate of a product, irrespective of the application rate of the main tank mix.

Effective cleaning can be carried out from the cab without any problems thanks to the complete integration of the system into the liquid circuit and machine operation.

RTK steering system from Trimble

A Trimble steering system is now available as a factory-fitted option for the Pantera's automatic track guidance system. This gives the customer a second supplier in addition to the TOPCON steering system, which is already well-known and also available from the factory, to equip the sprayer with the precise, individual needs of the farm.

The Trimble steering system comprises of a "GFX 1260" ISOBUS terminal, which also serves as the operator terminal for the Pantera sprayer, and the "NAV-900" GPS receiver.

The steering system can be pre-equipped for either an Egnos signal or RTK accuracy. The customer has access to the full functionality on the Trimble terminal, including all the necessary activations. These include, for example, VariableRateControl for site-specific crop protection or Section Control for the use of individual nozzle control with up to 96 part-width sections. In addition, there is the option of wireless job management and remote monitoring of the sprayer using the Trimble Ag software.

- High flexibility for a wide range of arable farming systems with infinitely variable track width adjustment from 2.25 m to 3.00 m

- Intelligent chassis technology for maximum ride comfort, minimum wear and low unladen weight

- Significant increase in flexibility and savings in labour time and pesticides thanks to the DirectInject direct injection system

- Precise crop care with RTK steering system - customised to individual farm conditions

Gallery