AmaSelect twin

More precision and flexibility with the customised AmaSelect extension kit

With AmaSelect twin, AMAZONE presents an innovative solution for precision application in plant protection - optimally adapted to the operational conditions, thanks to a wide scope of options for the 25 cm nozzle spacing and designed for the most stringent demands in professional crop care.

AmaSelect - the sophisticated all-rounder

The well-established AmaSelect nozzle body stands for precise plant protection, flexible application methodology and a long service life thanks to its well thought-out, simple design.

New: AmaSelect twin - 25 cm nozzle spacing with new possibilities

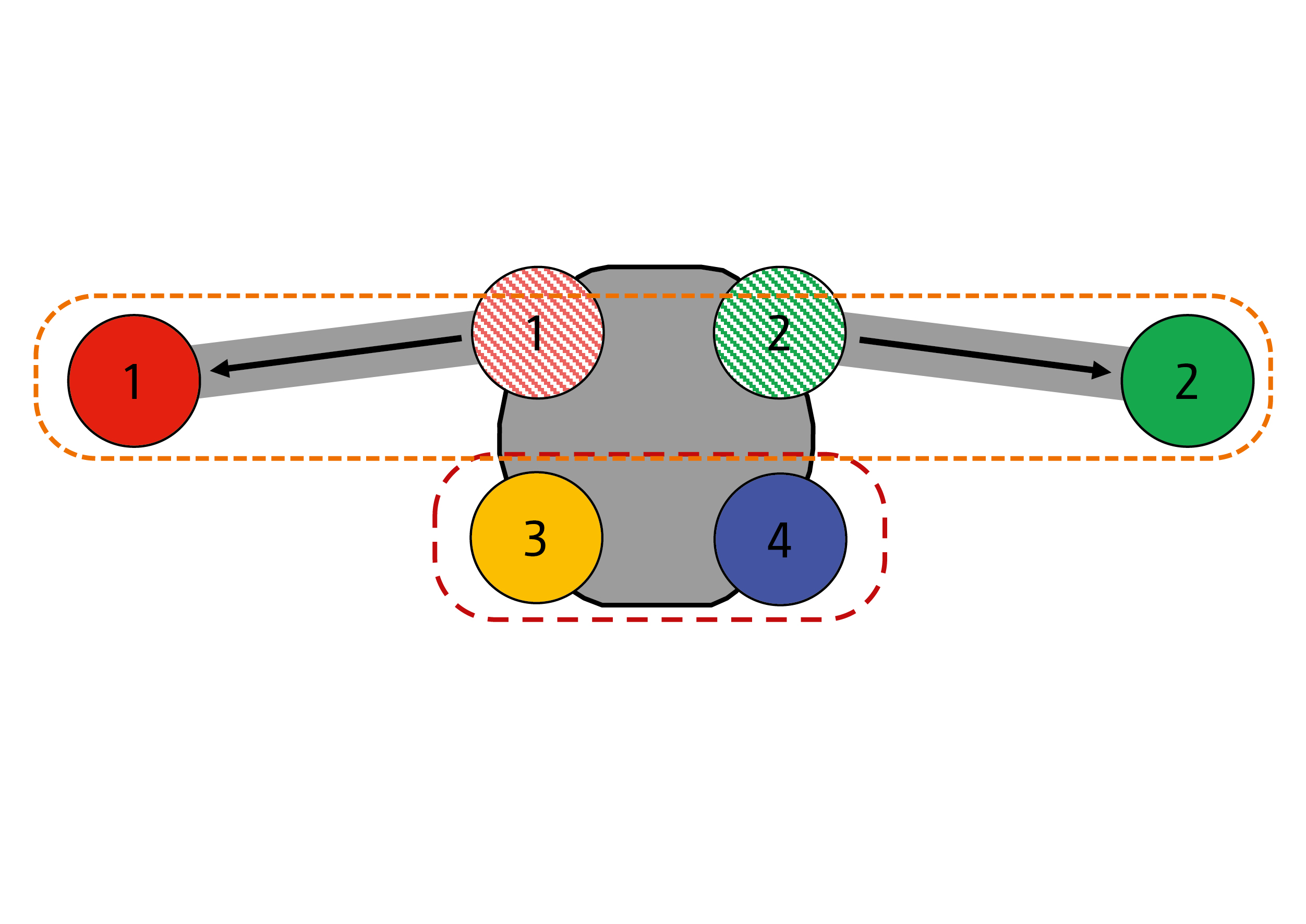

The new twin series comprises of two different extension kits: 2-2-2 and 2-1-2. Both offer 25 cm nozzle spacing, but differ in their functionality. AMAZONE thus offers a customised nozzle arrangement for all farms:

AmaSelect twin 2-2-2 - the cereal cropping solution

With AmaSelect twin 2-2-2, the flow from positions 1 and 2 is split between 2 nozzles having a 25 cm nozzle spacing. This means that the automatic nozzle change function is now also available at this narrower nozzle spacing. For the operator, this means that the full range of variation in forward speed and application rates can be used and, at the same time, application quality is optimised and the boom height can be lowered further for less drift. Curve compensation can also be used with the extension kit. The two remaining nozzle positions on a 50 cm nozzle spacing can still be used and are available for other nozzle types for specialist applications such as liquid fertilisation.

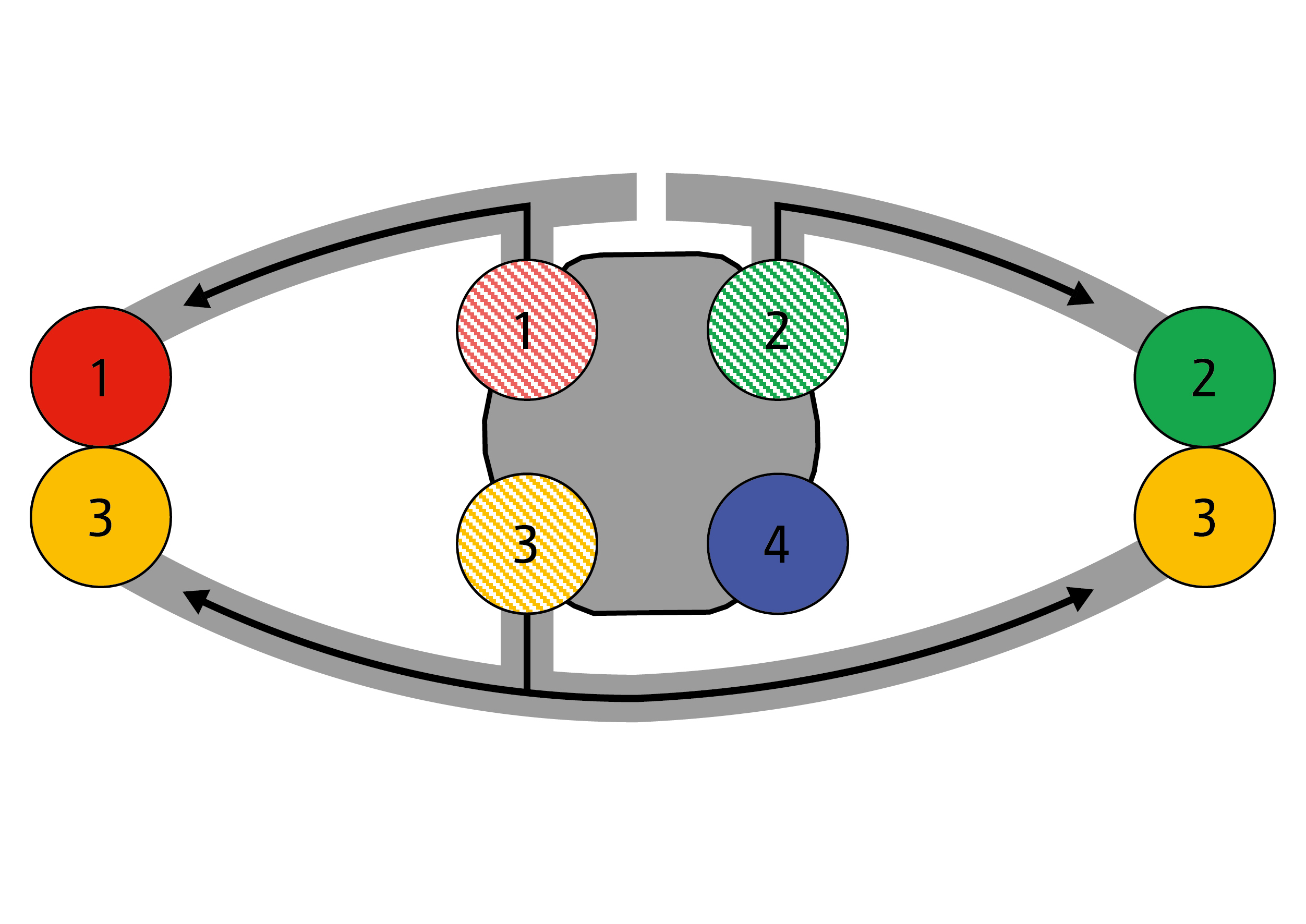

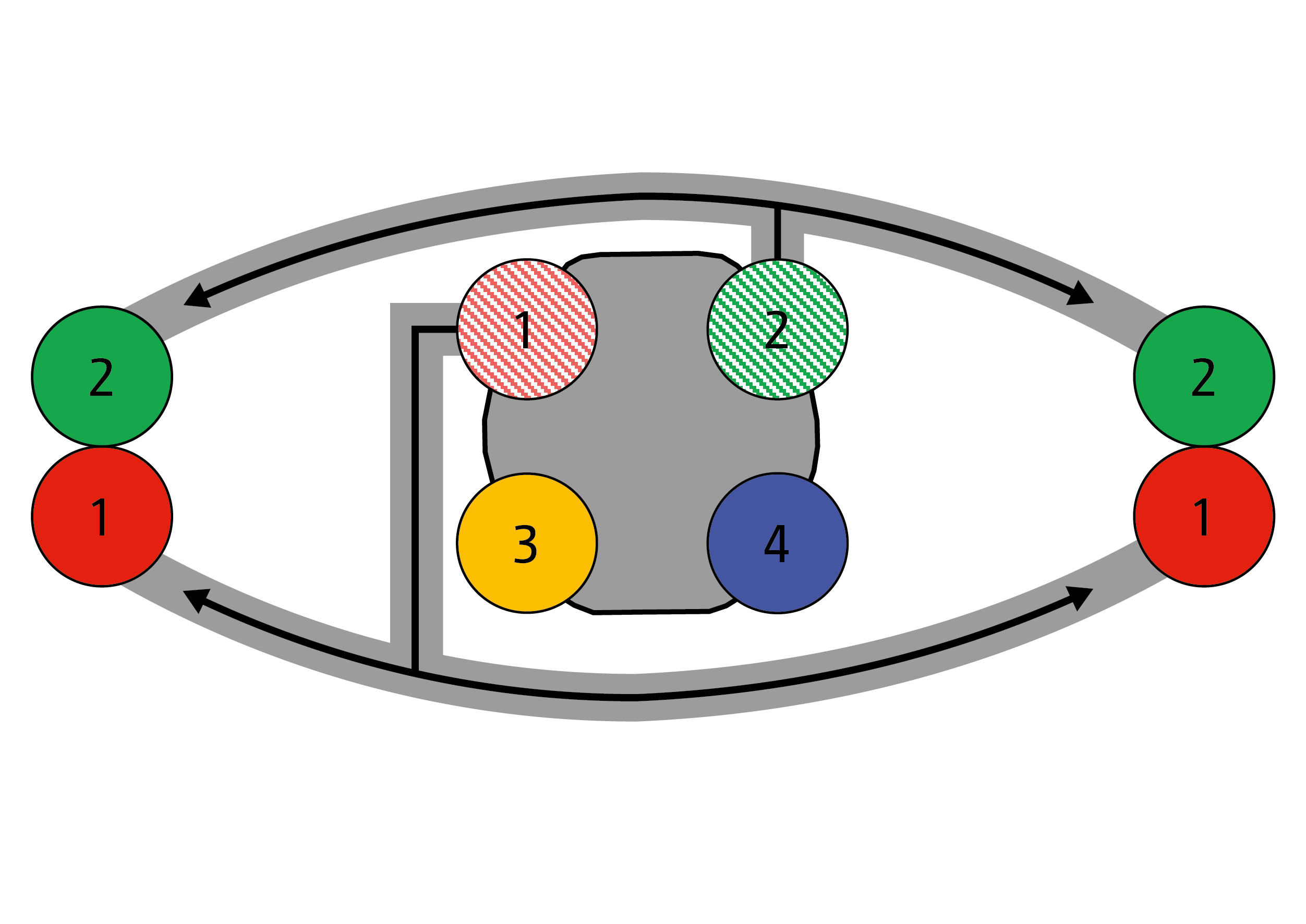

AmaSelect twin 2-1-2 - the row crop option

The AmaSelect twin 2-1-2 extension kit has been specially developed for use in row crops such as potatoes with 75 cm row spacing. Nozzle positions 1 and 2 are displaced to the left or right and, just as with the simple extension kit, each nozzle can be controlled individually with AmaSelect Row.

In contrast to the simple extension kit, the AmaSelect twin "2-1-2" offers an additional advantage: The liquid flow from position 3 is split between 2 nozzles with 25 cm spacing. Position 4 remains available as usual at 50 cm. This means that, in addition to the special solution for band spraying, a further 25 cm nozzle spacing is available for full-width application. The automatic nozzle change and the ability to combine positions 3 and 4 are also retained here so that variable forward speeds and application rates as well as curve compensation are entirely possible.

With AmaSelect twin, there is no compromise between maximum precision at 25 cm nozzle spacing and the tried and tested AmaSelect functions, such as automatic nozzle switching or band spraying, which make plant protection application flexible, efficient and needs-based.

AmaSelect - the simple solution to many application scenarios

AmaSelect offers a wide range of functions to simplify farm work. The LED individual nozzle lighting ensures safe working at night - when conditions are often at their best. With the standard individual nozzle control in combination with Section Control, work is child's play, even in irregular fields thanks to the 50 cm part-width sections - with virtually no overlaps.

However, the special feature of the AmaSelect is its intelligent nozzle control.

Automatic nozzle changeover and nozzle combination

In addition to manual switching, AmaSelect can change over and combine nozzles fully automatically depending on the spray pressure. This function offers the operator the option of flexibly adjusting the forward speed or application rate depending on the situation, whilst the droplet spectrum remains within the desired range.

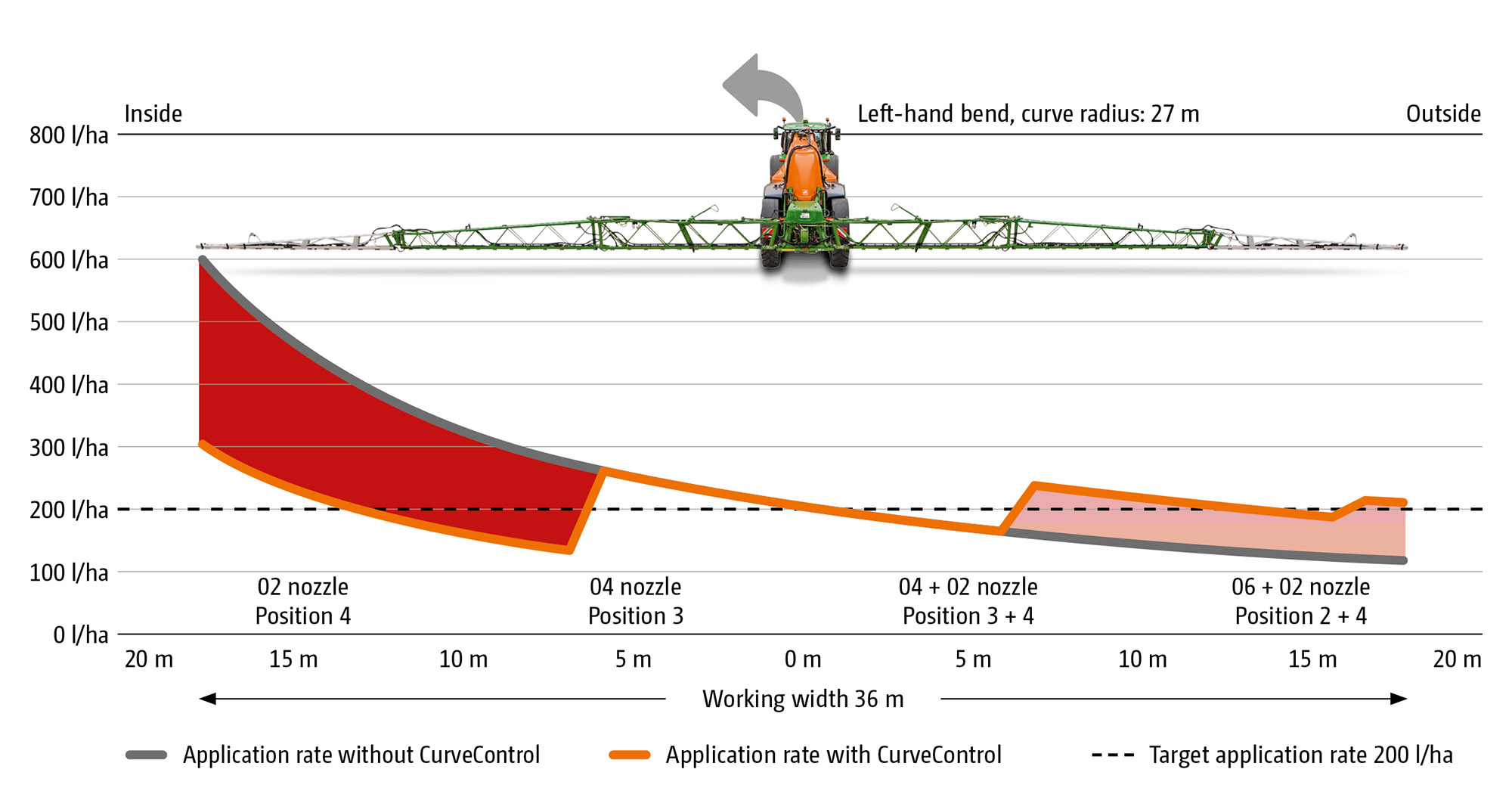

CurveControl curve compensation

When spraying around curves, there is the problem of overdosing on the inside and underdosing on the outside of the pass. There is a risk of crop damage on the inside of the boom and weed infestation and resistance at the outside.

The AmaSelect CurveControl solves this problem by automatically adjusting the nozzle size depending on the radius of the curve in order to maintain the desired application rate as precisely as possible over the entire length of the boom.

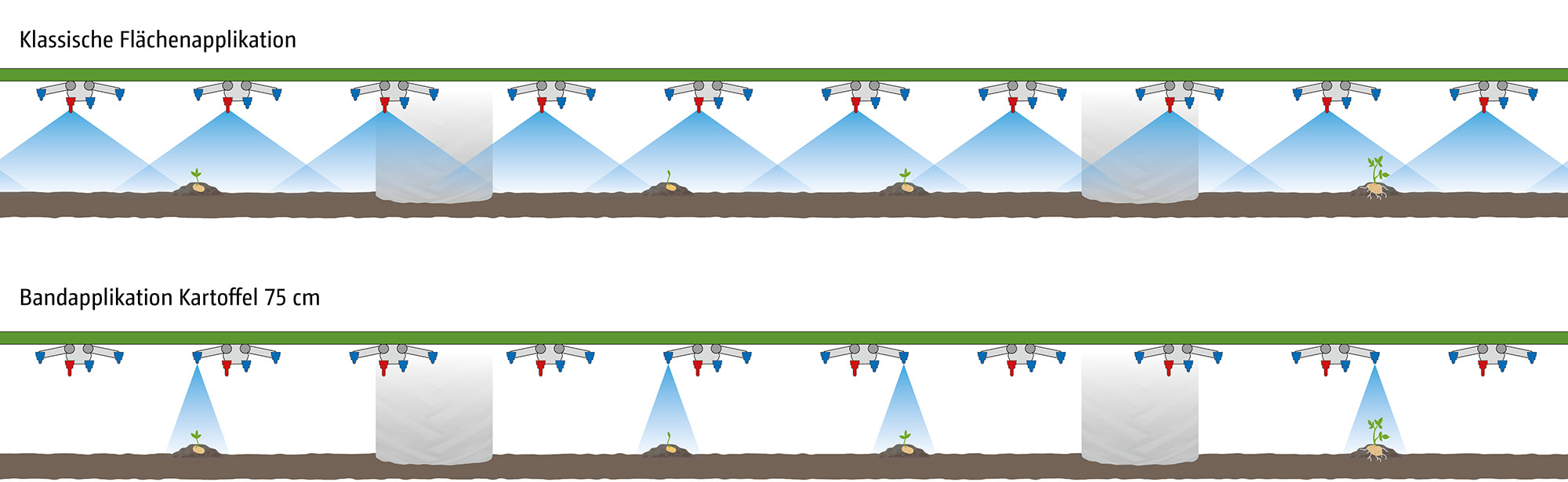

AmaSelect Row - the clever band spraying application

Successful band spraying demands high input from the operator. Depending on the situation, it may be necessary to switch between nozzles, change the application rate and adjust the height of the boom if necessary.

The AmaSelect Row significantly simplifies this requirement. The operator just needs to enter the row spacing and the application rates. To switch from band spraying to full width application, all you have to do is press a button: the system automatically switches from the band nozzle to the full width nozzle and adjusts the application rate and the height of the boom. AmaSelect Row therefore makes band spraying practical and offers significant potential savings.

AmaSelect Spot - precise plant protection, right on a point

With spot application, it is important to switch the nozzles quickly in order to keep the spot areas as small as possible. In addition, the amount of data on the spot maps can be a problem where there are high weed populations.

In combination with an AmaTron 4, AmaSelect Spot enables precise spot application. Thanks to the low data rate through using the spot format and the fast switching of the nozzle body, reliable and practical spot application is possible.

25 cm nozzle spacing - more precision for specialist applications

With the optional extension kit, 2 of the 4 AmaSelect nozzles are relocated by 12.5 cm to produce 25 cm nozzle spacing.

A reduced nozzle spacing can offer many advantages in practice: the lower boom height produces a reduction in drift, particularly around field boundaries. At the same time, the penetration and thus the effectiveness of the action is improved, especially in dense crop stands.

In combination with the AmaSelect Row and AmaSelect Spot, the 25 cm nozzle spacing offers further advantages. Band spraying is particularly common in potatoes with a row spacing of 75 cm. AmaSelect Row only switches on every third nozzle of the extension kit, for example, in order to only treat the row.

The 25 cm nozzle spacing also enables more precise application for spot spraying. Thanks to special spot spraying nozzles, spot areas with a sharp outline and optimum distribution can be guaranteed.

- Perfect application quality with both flexible forward speeds and application rates

- Automatic nozzle change and curve compensation with 25 cm nozzle spacing

- The optimum nozzle configuration for every application - without changing nozzles manually

Gallery