AmaConnect – smart data for intelligent machinery

The basis for more than just a connection

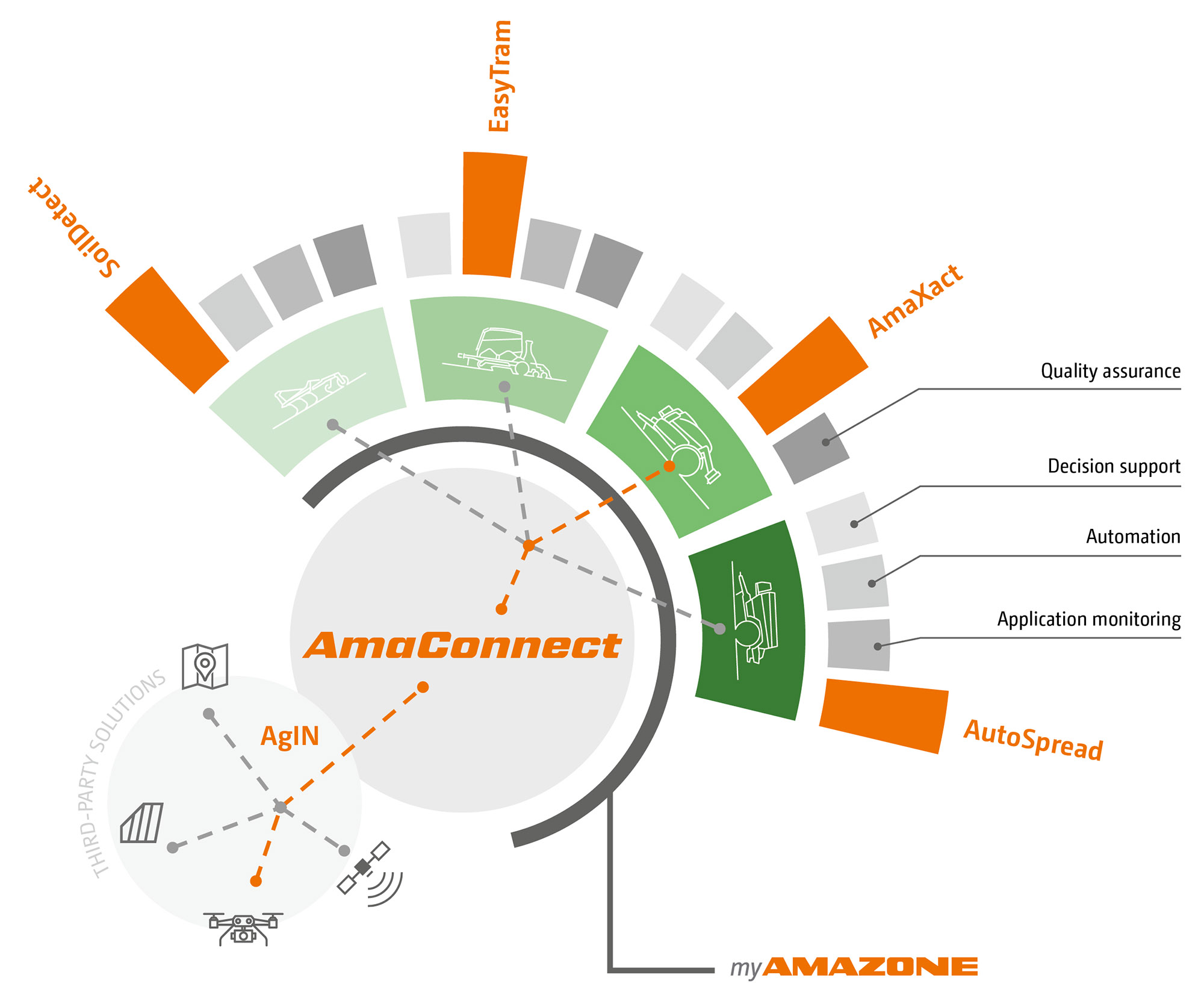

With the AmaConnect cloud-based data platform, AMAZONE offers the perfect, simple solution for modern farm management and complex work organisation. The focus is on the intelligent networking of AMAZONE machinery via the in-house developed connectivity unit, AmaConnect. This enables the near real-time transmission of machine data and application data to the data platform, which is fully and seamlessly integrated as a module of myAMAZONE.

AmaConnect makes it easy to save and analyse the transmitted work data and telemetry data from the networked implement.

The aim of the AmaConnect data platform is to turn agricultural implements into digital partners – for greater efficiency, transparency and sustainability on the farm. The functions range from the live monitoring of near real-time transmission of machine use and workload to the automatic documentation of legally relevant evidence and proactive maintenance using sensor systems and remote support. This allows non-productive times, overlaps and consumption to be monitored, while downtimes can be analysed and operating costs reduced. Examples of practical applications already include SoilDetect for recording soil data during the pass, EasyTram for creating tramlines with application maps, AmaXact for pressure-independent control of the application rate of plant protection agents with pulse width frequency modulation and AutoSpread for autonomous adjustment of the spreader by measuring the spread pattern of the fertiliser application.

The intelligent implement learns during operation

In future, AMAZONE product lines – from soil tillage, seed drills and fertiliser spreaders through to plant protection kit, groundcare and aftersales service – will be represented with digital functions on the AmaConnect data platform. The digital functions focus on operational support in the areas of decision-making, automation, application monitoring and quality assurance. In a first step, the focus is on pure machine connection, in order to create a stable database for corresponding functions.

Another focus is on data sovereignty: users retain full control over their data at all times, supported by transparent approval processes. At the same time, the digital verifiability of machine usage increases the resale value of used machines.

Future-proof compatibility thanks to AgIN

The AmaConnect cloud-based data platform can be updated and is open to third-party solutions,for instance, via initiatives such as the Agricultural Interoperability Network (AgIN) of the Agricultural Industry Electronics Foundation (AEF).

The AgIN initiative defines functional interfaces between implements, farm management systems and cloud services. The consistent consideration of open standards enables cross-manufacturer compatibility, increased efficiency in work processes, future-proof integrations and open collaboration.

As a result, the AmaConnect data platform fits seamlessly into existing digital ecosystems and enables data-based decisions based on aggregated findings about work results, applications or resource utilisation. Be it supplementation with data from other sources, machine jobs from other platforms or the integration of other intelligent services, AmaConnect is designed for flexibility and grows with the requirements of modern farm management.

The AmaConnect data platform can be used via a web portal without the need for training or previous knowledge. With this solution, AMAZONE bridges the gap between mechanical engineering and the digitalisation of agriculture – and makes one thing clear: next-level agriculture starts with a connection.

- Central platform – Provides a bundled overview of all relevant operating and machine data in one place.

- Real-time monitoring – Enables live monitoring of machine status and operating parameters to optimise work processes.

- Efficient documentation – Automatic storage of work data to efficiently fulfil documentation obligations and internal analyses.

- Optimisation of work processes – Supports drivers and farm managers in the planning, execution and follow-up through structured data preparation.

- High compatibility – Interfaces to other digital systems and machine manufacturers via standards and AgIN interface.

Gallery