AMAZONE Report - Issue 46

Issue 46 - 02/2023

Magazine of AMAZONEN-WERKE for employees, customers and friends of the company.

You can also download the current issue here as a PDF file.

Report on the current situation

Following a turbulent and challenging first half of the year in the agricultural machinery sector, we are finally able to bring you some positive news. In spite of the ongoing challenges caused by unstable supply chains, geopolitical tensions and high inflation, the situation regarding the production and supply chain has fortunately stabilised somewhat. Our optimistic forecast from the spring did not play out as expected and the agricultural sector still faces many challenges. Nevertheless, we still have reason to be happy: two of our innovative products were awarded a silver medal at the Agritechnica exhibition. We also presented the impressive figures from the 2022 financial year at our international press conference on 12 September, 2023. AMAZONE ended the year with significant growth, increasing overall turnover to a new record high of 804 million euros. The consistently high export share of around 80% as well as a greater intensification in market development and new development in some European countries and North America contributed to this upsurge. We are very proud of our success because it underlines the resilience and flexibility of our corporate concept, even in turbulent times.

Visit us!

AGRITECHNICA 12.11. – 18.11.2023 Hanover Hall 9 | Stand C30

AMATECHNICA 23.05.2024 Hasbergen-Gaste

You will find more information about our award-winning new products at www.go2024.net as well as here.

A strong team and 140 years of tradition form the foundation of our family business. It is therefore very important for our business policy to have a long-term outlook. We are aware that we cannot simply rest on our laurels and must therefore continue to invest in the future, which is why we have implemented a series of measures in recent months: In order to ensure delivery capability, investments were made to extend the hall space in the Bramsche and Hude/Altmoorhausen plants. A new powder coating system was introduced in Gaste to increase quality and we are planning to support specialist retailers by setting up a workshop and exhibition area in the used machine centre (GMC) recently established at our Leeden location. In product development, our focus remains on innovation and sustainability. In view of the growing global population, constant reduction in farm land and unstable global climate, we hope to help the agricultural sector by providing modern technology and digital solutions to further prepare for the future and produce high-quality food.

As part of our flagship campaign "Ideas for our future", at Agritechnica we will be presenting a range of different new products designed to preserve valuable resources and save on operating materials. We are really looking forward to showcasing our ideas and solutions in Hanover and cordially invite you to visit our stand in Hall 9!

Christian Dreyer and Dr. Justus Dreyer

Partners in focus

Shared passion for agricultural machinery

Worch Landtechnik – Our reliable partner in Saxony-Anhalt

The productive collaboration between AMAZONE and Worch Landtechnik GmbH in Saxony-Anhalt is an impressive example of a long-term partnership. With six branches in the region, Worch Landtechnik is not only an outstanding trading partner, but also a first-class competence centre for harvesting equipment as well as groundcare and garden equipment.

The collaboration with AMAZONE initially involved just specific products, but the portfolio continued to expand over time. The entire AMAZONE range has been successfully on offer for several years now and, alongside Claas, occupies a central position in the Worch Landtechnik product range.

Worch's head office in Schora is the hub for first-class sales and service. The Raguhn, Zahna, Rackith, Samswegen and Genthin branches add to the company’s presence in Saxony-Anhalt, from the Zerbster Land and Fläming Nature Park to the region above Magdeburg. A dedicated team of around 90 employees live and breathe agricultural technology with a passion.

"Our highly qualified employees and trainees strive to meet customer demands on a daily basis. Everyone is an expert in their field", explains Thomas Worch, who runs the company together with Enrico Picht. "Our commitment and passion for agricultural machinery represent the driving force and guiding principles for the success of the company and its reputation among customers."

Since 2005, our experienced factory representative Wolfgang Gottschlich has been supporting all Worch branches in all matters relating to the AMAZONE product world. His many years of experience ensure seamless interaction between the partners.

Since 2005, our experienced factory representative Wolfgang Gottschlich has been supporting all Worch branches in all matters relating to the AMAZONE product world. His many years of experience ensure seamless interaction between the partners.

New products at Agritechnica 2023

Ideas for the agriculture of the future

The right product for everyone!

AGRITECHNICA: Hall 9 | Stand C30

You will find all the information about our award-winning innovations and new products here.

AMAZONE is presenting its latest products once more at Agritechnica, the world's leading trade fair for agricultural machinery. Under the motto "IDEAS FOR OUR FUTURE" we are facing the challenges of growing food worldwide. We have excelled in our role as specialists in "intelligent crop production" for more than 140 years and will continue to meet the future needs of the industry going forward. Good ideas, and the courage to implement them in each specific product, are already making a decisive contribution to sustainable food production.

Soil tillage: 400 Onland semi-mounted reversible plough

The Tyrok 400 semi-mounted reversible plough now has the option for on-land ploughing. The Tyrok Onland provides a high level of flexibility as a result of the quick and easy change between on-land or in-furrow operation. The new models are offered with a choice of 7, 8 or 9 furrows for tractors of up to 400 hp.

Seeding: Cirrus 9004-2C Grand trailed cultivator drill

The new cultivator drill for large-scale farms and contractors is available in a working width of 9 m with a row spacing of 16.6 cm. At first glance, the seed drill stands out due to its striking design. This is largely determined by the large seed hopper and the distinctive distributor head. Designed for solving current and future challenges in agriculture, the machine is characterised by its precise, flexible and efficient operation. Due to its easy adaptability to various field management concepts, it opens the door to future arable farming.

Precision seeding: Precea-TCC trailed precision air seeder

The range of precision seeders now includes the new trailed Precea models, in working widths of 9 and 12 m respectively. This variant, which has been developed specially for large-scale farms and contractors, stands out with its high-performance overpressure singling, large hopper capacities and the innovative Central Seed Supply seed delivery system. The high-precision seed placement ensures optimum field emergence, even at increased forward speeds of up to 15 km/h.

Fertilisation: ZG-TX – A combi spreader without compromise

The new trailed ZG-TX is setting standards in the combi spreader sector. Both granular mineral fertilisers and earth-moist limes can be applied precisely through the one machine by means of a simple conversion between the TS spreading system and the newly developed spreading unit for lime. The ZG-TX therefore combines the advantages of the TS spreading system, with its disc-integrated AutoTS for optimum border spreading results, with maximum efficiency when spreading lime. With the simple Special frame and the stronger Super frame, AMAZONE offers the right machine for any application.

Crop protection: Pantera 7004 self-propelled sprayer

The Pantera 7004 adds a further model in the self-propelled sprayer segment. The outstanding features of this new machine are its high tank capacity and the newly developed running gear. The Pantera 7004 combines high performance with first-rate driving characteristics and is ideal for large-scale farms and contractors who place the highest demands on efficiency and comfort.

SCHMOTZER hoes: Linear shift frame VR 2

The extremely compact design of the VR2 linear shift frame catches the eye and the frame offers impressive strength, especially when hoeing under the most difficult of conditions. The frame sets itself apart on account of its very high total travel range of 600 mm (300 mm left and 300 mm right). Optimum guidance of the hoe through row crops without them being damaged or hoed out is therefore guaranteed, especially on non-straight headlands and fields with slopes, where the tractor tends to drift.

Exhibition news

Good atmosphere at the Tarmstedt exhibition

Considerable interest in AMAZONE products

The 73rd edition of the largest specialist exhibition in Northern Germany came to an end in sunny weather. This year, the Tarmstedt exhibition attracted a total of 89,500 visitors over four days. 750 exhibitors presented their products across more than 18 hectares of outdoor space and in seven exhibition halls. Our factory representative for the northeast Lower Saxony region, Maximilian Homann, reported on a host of interesting customer discussions and numerous customer visitors to our stand. We presented a broad selection of equipment from each machine category. Our visitors showed particular interest in the plant protection and seeding equipment, and the hoes from Schmotzer also attracted some visitors to our stand. Our groundcare equipment was a great source of attraction, especially since the region is also home to many equestrian businesses. Overall, AMAZONE enjoyed great success at the Tarmstedt exhibition once again, although it is an event heavily influenced by the weather. On Friday, potential customers were slightly on edge and had one eye on the start of the harvest because of the sunny weather – so the following two days were not as busy. The rain on Sunday evening ultimately prompted the biggest rush of visitors on Monday, and as a result, some machines were sold directly from the stand by our sales partners, and delivered to customers on the Tuesday directly after the show. The mood in the agricultural industry and thus the associated interest in machinery can be considered still to be positive.

Machinery news

Congratulations AmaTron!

The 100,000th unit goes out

The 100,000th AmaTron gives AMAZONE the opportunity to look back on a successful history of development of the versatile ISOBUS terminal. The development started at AMAZONE back in 1985 with the first AmaTron generation. This allowed the fully automatic regulation of the desired application rate with fertiliser spreaders. An increasingly wide range of functions for the monitoring and fully automatic operation of agricultural machinery were added in the years that followed. In the meantime, the terminal can be used on all AMAZONE fertiliser spreaders, plant protection equipment and seed drills as well as on ISOBUS-compatible machines from other manufacturers. The current version, the AmaTron 4, offers the user the highest operator comfort, meaning that easy working becomes a matter of course, even with complex machines. This is because the distinctive feature of the AmaTron 4 is the intuitive operation of all the functions thanks to the logical menu navigation. The AMAZONE design team has been responsible for the external design and the easy operability of the AmaTron 4. They played a key role in designing both the shape of the terminal and the concept for the operator navigation, i.e. the hardware and software user interface. The electronics and software were developed in close cooperation with the company Müller-Elektronik.

The AMAZONE Profihopper turns 25!

1. The choice of professional gardeners

THE AMAZONE Profihopper turns 25!

Production of the Profihopper began at AMAZONE S.A. in Forbach 25 years ago. This versatile machine for maintaining green spaces has developed over time into the most important product out of the Forbach factory. It has been continuously developed to be suitable for mowing, scarifying and collecting leaves.

From around the world

Romanian customers appreciate the quality

AMAZONEN-WERKE S.R.L. in Romania

In 2019, AMAZONE-WERKE S.R.L. started operations in Romania. Under the leadership of managing director Franz Jakoby, the company and team sell agricultural machinery across the country and offer comprehensive support for local dealers.

When selecting agricultural machinery, customers focus on outstanding quality. AMAZONE regularly attracts attention in this area due to its diverse product range. The most popular equipment among Romanian farmers includes the ZA-TS fertiliser spreader, Precea precision seeder, Catros compact disc harrow, Ceus tine & disc combination cultivator, Pantera self-propelled sprayer and the UX trailed sprayer. Farmers can experience the advanced technologies of these machines first-hand in field demonstrations organised by Mr. Jakoby and his team.

Mr. Jakoby's primary goal is to raise awareness of AMAZONE technology in Romania and continue to convince farmers of the exceptional quality of these machines. Ultimately, exceptional product quality combined with reliable service lays the foundation for implementing new and innovative cultivation methods that enable farmers to work more effectively and efficiently in times of increasing cost pressure.

AMAZONE at the Obihiro Farm Show

Successful trade fair presence in Japan

Our stand at the international Obihiro Farm Show on the Japanese island of Hokkaido was very well attended. AMAZONE was represented in Japan by our importer "ISEKI Implements", who has been our successful working partner for over 50 years. In addition to our products, ISEKI also sells machines from KRONE, WEIDEMANN and WELGER. The exhibition included the Catros compact disc harrow with knife roller, the ZA-TS mounted spreader with WindControl, drill combinations of KE with Cataya and KE02 with Precea, the Cenio mounted cultivator and an extra area for electronic solutions such as EasyCheck from AMAZONE. The highlight, however, was our Pantera 4504 self-propelled sprayer. Although products from our complete range are sold here, it is the ZA-M and ZA-V mounted fertiliser spreaders, D9 mounted seed drills and Catros compact disc harrows that are the best-sellers.

PANTERA 4503 – Scarred by war, rejuvenated by local experts

SC AMAZONE UKRAINA

In the autumn of 2022, one of our PANTERA self-propelled sprayers was seriously damaged by the effects of war. The destroyed machine appeared to be damaged beyond repair. Amazingly enough, the team from SC AMAZONE UKRAINA was able to resurrect this self-propelled sprayer. It has been back working on the fields of Persche trawnja GmbH in the Charkiw region since May 2023 – an impressive comeback.

Persche trawnja GmbH, which is located in the village of Svitlychne in the Bohodukhiv district, was attacked by Russian troops, as were many other businesses. The existing machine fleet was severely affected.

The owner of the PANTERA, Volodymyr Reva, commissioned the repair of the machine in the autumn of 2022. Experts were shocked at its condition at first sight. Extensive damage to the chassis, tanks, boom and other parts was diagnosed. In spite of financial difficulties, the farmer decided to repair as much as possible and the SC AMAZONE UKRAINA team took up the challenge of breathing life back into the PANTERA. The experts did an excellent job repairing the machine and it looks like new today!

Despite the ongoing uncertainty caused by the war, we are proud to have provided support during these challenging times. The case of the PANTERA 4503 not only underlines the quality of our machines, but also emphasises the partnership between AMAZONE and local farmers.

Nienhuis-Roebroek farm in Groningen with one of the first UX models with a 45 m boom from Bramsche

Strong partnership in the Netherlands

Nienhuis-Roebroek is an AMAZONE Premium customer with approx. 155 hectares in Groningen (Netherlands). The two operations managers Annemarie Nienhuis-Roebroek and Klaas Nienhuis and their employees grow, amongst other things, sugar beet, seed onions and winter carrots, but the focus is primarily on cereal farming (64 hectares) and potato farming (50 hectares) as seed producers.

In February, Klaas Nienhuis visited our factory in Bramsche together with Niels Kruizenga, a salesman from our Dutch dealer Van der Maar. After a detailed consultation and a tour of the company, Nienhuis made the decision to purchase the new AMAZONE UX 5201 Super crop protection sprayer with a 45 metre boom for his farm. Before visiting Bramsche, Nienhuis had discussions with other UX users and was enthusiastic about the technology right from the start. Ultimately, it was the ContourControl boom guidance, the SwingStop active vibration dampening and the overall operating comfort that won him over. Nienhuis-Roebroek is now the proud owner of one of the first UX with 45m booms that came off the production line at our factory in Bramsche.

HIGHLIGHTS

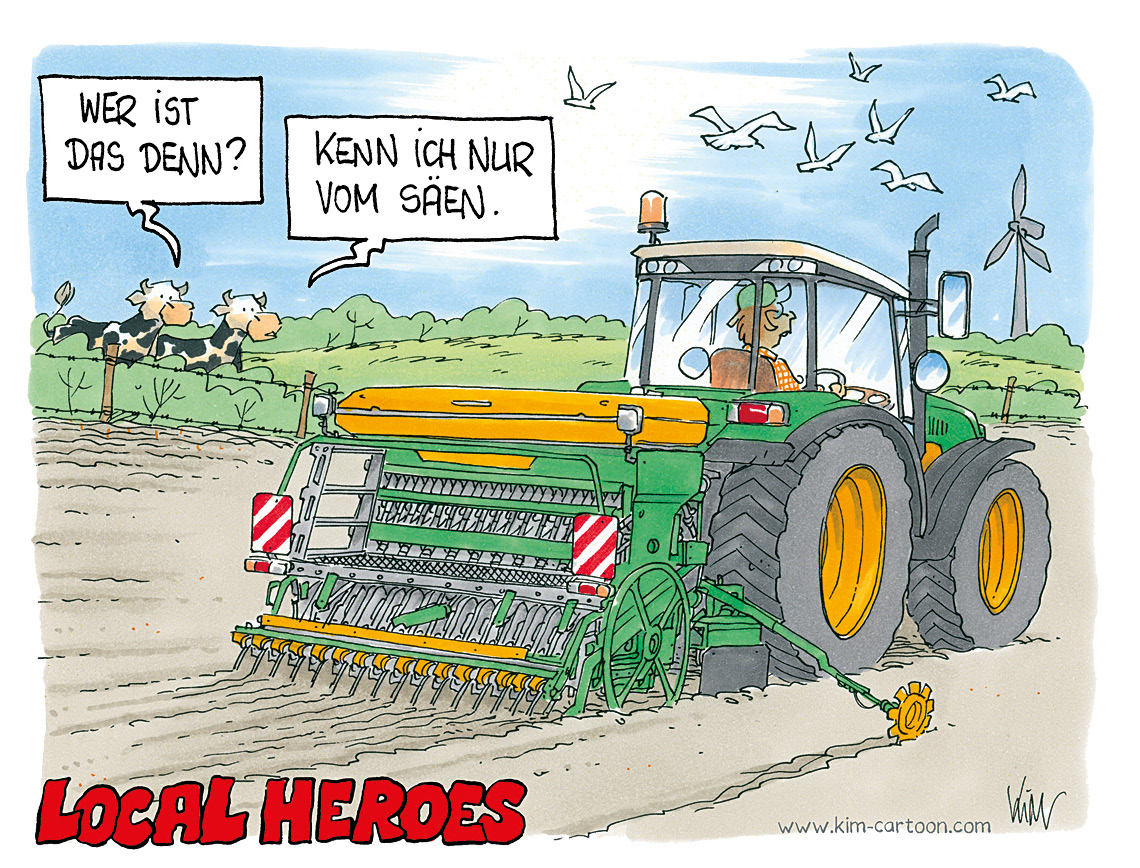

AMAZONE is also a piece of home

Interesting discovery brings back fond memories

In April of this year, we received a clipping from a daily newspaper printed in Schleswig-Holstein. It was sent in by Sabine Stechmann and showed a cartoon that clearly depicted an AMAZONE seed drill. The image reminded the sender of her childhood, as both her parents had worked at AMAZONE. Her father, Erich Huffnagel, worked as a foreman in production, while her mother Anneliese worked in sales. During her school holidays, Ms. Stechmann worked in the spare parts warehouse and still remembers an order for " track marker discs". Since she didn't know the function of these parts on our machines, she went on a tour of the factory and finally discovered where they fitted on our drill combinations. Even after 40 years, the sight of orange and green agricultural machinery still brings a smile to her face and reminds her of home. So she came up with the idea of sending the clipping over to share her discovery with us. Ms. Stechmann has worked as a veterinarian in Rendsburg for many years.

This story demonstrates the positive connection of former employees and the attachment of entire families to AMAZONE. Many people associate more than just products with AMAZONE, making us part of a wide variety of different life stories.

Topping-out ceremony for expansion

New production halls strengthen the AMAZONE factory in Altmoorhausen

Almost 15 years after the ground-breaking ceremony at the Altmoorhausen site, the topping-out ceremony for two new production halls was celebrated on 7 July, 2023 as part of the fourth expansion. They cover a total of 5,280 m² of floor space and extend the covered area of the production facility in Altmoorhausen to around 32,500 m². A prefabrication area will be added to the halls to allow the manufacture of individual parts and components directly on site.

Numerous guests from the district, municipality, local neighbourhood and AMAZONE workforce accepted the invitation to the topping-out ceremony. In addition to Christian Dreyer and his wife Bettina, guests from the owner family of the AMAZONE Group attending the event in Hude also included senior partner Klaus Dreyer with his wife Malu and Dr. Stephan Evers as managing director and plant manager. After the welcome speech by Dr. Evers, speeches were given by Hude mayor Jörg Skatulla and county commissioner Dr. Christian Pundt. The keynote speech was given by Mr. Nieters from the structural engineering company Hoving & Hellmich. To conclude the official part, Christian Dreyer gave a speech From left: Dr. Stephan Evers (Managing Director for Production, Quality, IT), Klaus Dreyer, Malu Dreyer, Christian and Bettina Dreyer, Volker Osterloh (Head of the Paint Shop for Hude and Altmoorhausen) and Günter Aljets (Operations Manager for Hude and Altmoorhausen) reviewing the development of the Altmoorhausen site and explained that the construction of the two halls represented a new milestone in the development of the plant. A snack cart and a drinks cart provided a few creature comforts during the cosy gathering that followed.

AMAZONE embarks on a bicycle tour for peace

Trainees implement the idea of Johannes Trieb

On the occasion of the 375th anniversary of the Peace of Westphalia, the Osnabrücker Land tourism company organised a bicycle tour together with Münsterland e. V. It was held over two weekends in April along the 163 kilometre long Peace Route between Münster and Osnabrück. Our trainees from AMAZONE helped implement an idea from the artist and sculptor Volker-Johannes Trieb and developed a type of printing machine for his transport bicycle that sprayed a message of peace onto the asphalt using biodegradable paint along selected sections of the route and in front of the town halls. Training manager Tim Schade and trainee Matthis Kühn worked on the special printer bicycle for a few months with outstanding ingenuity and commitment. During the process, they developed and installed a pump, paint container, control and a nozzle module on the bicycle platform. The design was successful. At the opening event in Osnabrück, Trieb sprayed Erich Maria Remarque's quote "I always thought everyone was against war" in 40 cm large letters on the pavement in front of the town hall.

IN BRIEF

54 years of reliable operation

AMAZONE D4

Julia Brügger runs a dairy and arable farm together with her father in Straelen on the Lower Rhine. In 1969, her grandfather bought an AMAZONE D4 for 2,500 DM from the company Terhöven. Unfortunately, the working width of 2.5 metres is too narrow for the family's current needs, so a decision was made to purchase a new seed drill. Due to the reliability of the old D4, they chose another AMAZONE product. In the future, sowing will now be carried out by a D9-3000 Super with RoTeC coulters. The old D4 will then begin its journey back home to our factory in Hasbergen-Gaste. Now that three generations have successfully worked with this seed drill, it will take pride of place in our museum.

This is just one example of many family businesses that are sold on the quality and longevity of our machines. The new D9-3000 Super will become a long-term, loyal companion alongside other AMAZONE machines that the Brügger farm uses for fertilisation and crop protection.

AMAZONE grain cleaner with elevator

Once upon a time

The grain cleaning machine was the original product from the Heinrich Dreyer factory in Gaste, which was renamed Amazonenwerke in around 1910. The grain cleaning machine, which is used to separate the chaff from the grain and was popularly known as the "winnower", received a medal at the DLG exhibition in Bremen in 1891 and was then named AMAZONE. Over the years that followed, the original machine developed into a selection of different-sized cleaners with a large range of accessories. As you can see here, an elevator was even incorporated for loading the cleaned grain from sacks. These cleaning machines were manufactured by AMAZONE until the 1950s. In the end, they were only available in small numbers and therefore in only one standard size until combine harvesters finally emerged onto the market and took over the job of cleaning the grain.

Digital customer portal

myAMAZONE for maximum performance and an extended guarantee

Guarantee on premium painting

We have been using a new premium painting process for the ZA-V and ZA-TS mounted fertiliser spreaders and the ZG-TS bulk fertiliser spreader since the 2022 model year. The process includes cathodic dip painting as a primer and a powder coating for increased protection against mechanical damage. AMAZONE now offers a special guarantee for these models in the form of a seven-year manufacturer guarantee against rusting through. The guarantee can be easily requested free of charge in the myAMAZONE customer portal under the terms and conditions stated there.

https://amazone.net/en/myamazone

We have taken interaction with our customers to a whole new level with the myAMAZONE online portal. It enables farmers and users of AMAZONE machines to optimise their machine output whilst benefiting from extended guarantees.

Registering for the myAMAZONE portal is free and opens the door to a variety of benefits.

Users have the option of extending the manufacturer's guarantee for their machines. It extends over 24 months and can even be extended to 36 months for the Pantera self-propelled crop protection sprayer and the Profihopper self-propelled mower/collector.

In addition to all guarantee options, many information options for existing AMAZONE agricultural and groundcare machinery can also be used and managed in the personalised customer area. Operating instructions, safety instructions and setting recommendations are easily accessible, and spare parts lists can also be accessed directly. One highlight of the portal is the SmartLearning feature, which offers interactive video training for AMAZONE machine operation. The feature makes an important contribution to ensuring machines are used professionally as well as increasing efficiency and safety.

AMAZONE PEOPLE

Long-standing employee Christian Peters

Our expert for production optimisation in Hude and Altmoorhausen

AMAZONEN-WERKE has been accompanying Christian Peters on his journey since September 1997. At that time, he began his training as a tool mechanic at the Hude factory and after successfully completing it, he worked in our company metalworking shop for six months. He then decided to study mechanical engineering in Bremen and returned to the company in April 2006 as a graduate. After completing his dissertation, he was hired as an engineer in equipment design.

Within a short time, Mr. Peters had assumed responsibility for project work and planning for different investments in the Hude plant. In collaboration with business and operations management, he was also appointed to design our production site in Hude-Altmoorhausen. He was one of the few present from the very beginning and from the very first drawing. Due to his extensive expertise in optimising factory development, Mr. Peters has, for some years, been a valued expert in the design process when it comes to optimising manufacturing.

Mr. Peters has been married since 2011 and lives with his wife and two children (Leefke 8 years and Peeke 6 years) in Falkenburg. We greatly appreciate Mr. Peters's commitment to our team and are looking forward to undertaking successful projects with him in the future.

Did you know that ….

Astonishing facts and figures

more than

machines have been manufactured by AMAZONE over the last 140 years?

of the electricity consumed within the company is actually generated by the company?

new products were presented at Agritechnica in November 2023?

young people started training or dual study programs at our sites/plants in Germany on 1 August?

New faces in our German sales team

Two specialists for a successful future

On 1 June, 2023, Arne Thomsen joined our team as a factory representative for the Schleswig-Holstein region. The qualified agronomist and experienced field representative replaces Dirk Heutmann, who has gone into a well-deserved retirement after working for AMAZONE for around 22 years.

Another new addition to the role of factory representative is Dan Muckel. After two successful years in sales promotion at AMAZONE, he has proven his worth and on 1 September, 2023, took over the sales area of the Rhineland-Palatinate/Saarland region from Udo Linck, who, like Dirk Heutmann, has been a loyal servant to AMAZONE for 22 years.

We wish Dirk Heutmann and Udo Linck all the best and, above all, good health during their well-deserved retirement. At this point, we would like to express our sincere thanks for their loyal work, which has shaped the market over the last two decades. We warmly welcome our new colleagues Arne Thomsen and Dan Muckel, who we are certain will make a valuable contribution to our future development.

Pantera 7004 wins prestigious design awards

Outstandingly beautiful

Pantera 7004 wins prestigious design awards

Product design has become increasingly important in recent years. It can create great added value for the product and the brand, especially if its operation is simple and intuitive as well and it stands out from the products of market competitors.

With a capacity of 7,000 litres, our self-propelled Pantera 7004 is the new flagship of the AMAZONE brand. The enormous working width and large tank capacity enable farmers to protect their plants from diseases and pests in a more efficient and more environmentally friendly way. With a new chassis, the Pantera moves agilely and nimbly over any surface, just like its namesake. The design has been consistently revised and every detail follows a clear design concept that visually encapsulates efficiency, comfort and trust in the AMAZONE brand.

Convinced of its impressive design, we entered the Pantera 7004 into two independent design awards this year to have the design quality of the overall machine and its user interfaces assessed by neutral experts. To our great delight, the machine impressed both juries of international design industry experts. Our self-propelled machine won the "IF Design Award 2023" and "Red Dot 2023" awards, which enjoy high recognition worldwide and are becoming increasingly valuable for product advertising.

The "Red Dot Design Award" ceremony took place at a gala in Essen in June. Due to its impressive size, our self-propelled machine was given pride of place directly in front of the Award Museum at the Zollverein Coal Mine Industrial Complex. A total of 1,200 guests from over 40 countries were able to examine the Pantera close up during the celebrations. It provided an impressive sight throughout the evening and received a lot of positive feedback from both the organisers and the expert audience.