DirectInject direct feed system

Quick, flexible and needs-based metered addition of plant protection agents

The demands on farmers and technology are constantly increasing with regard to plant protection. Flexibility in the selection of plant protection agents in the field becomes an increasingly important point here. From a plant establishment perspective, the needs-based application of specific products and active ingredients only in sections or on individual fields is a frequent response. There are also restrictions relating to environmentally-sensitive fields and bodies of water which the farmer must consider when selecting the plant protection agents. These requirements with respect to flexibility in plant protection are in stark contrast to the structural development towards larger sprayers for high work rates and economic use.

System overview

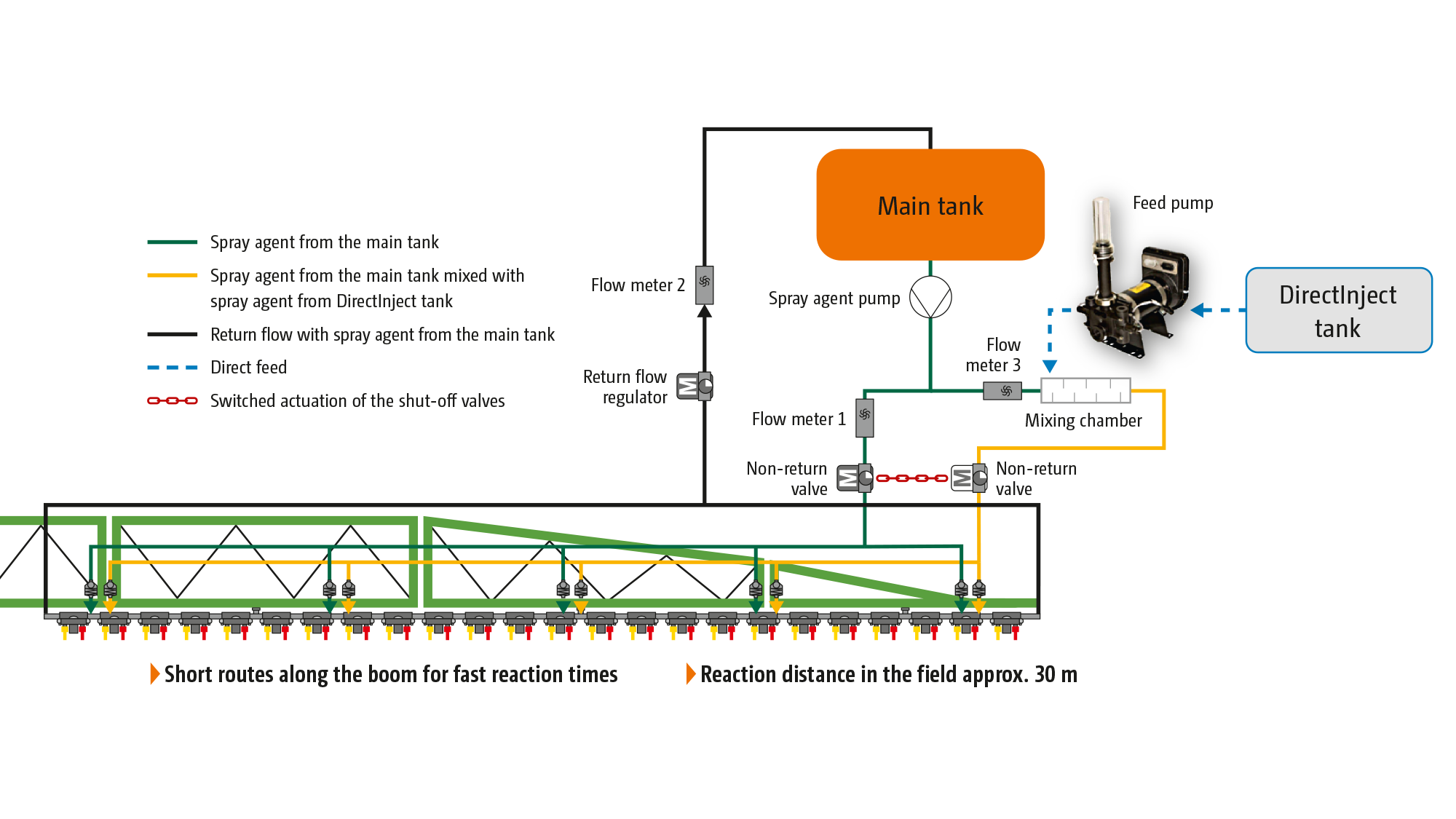

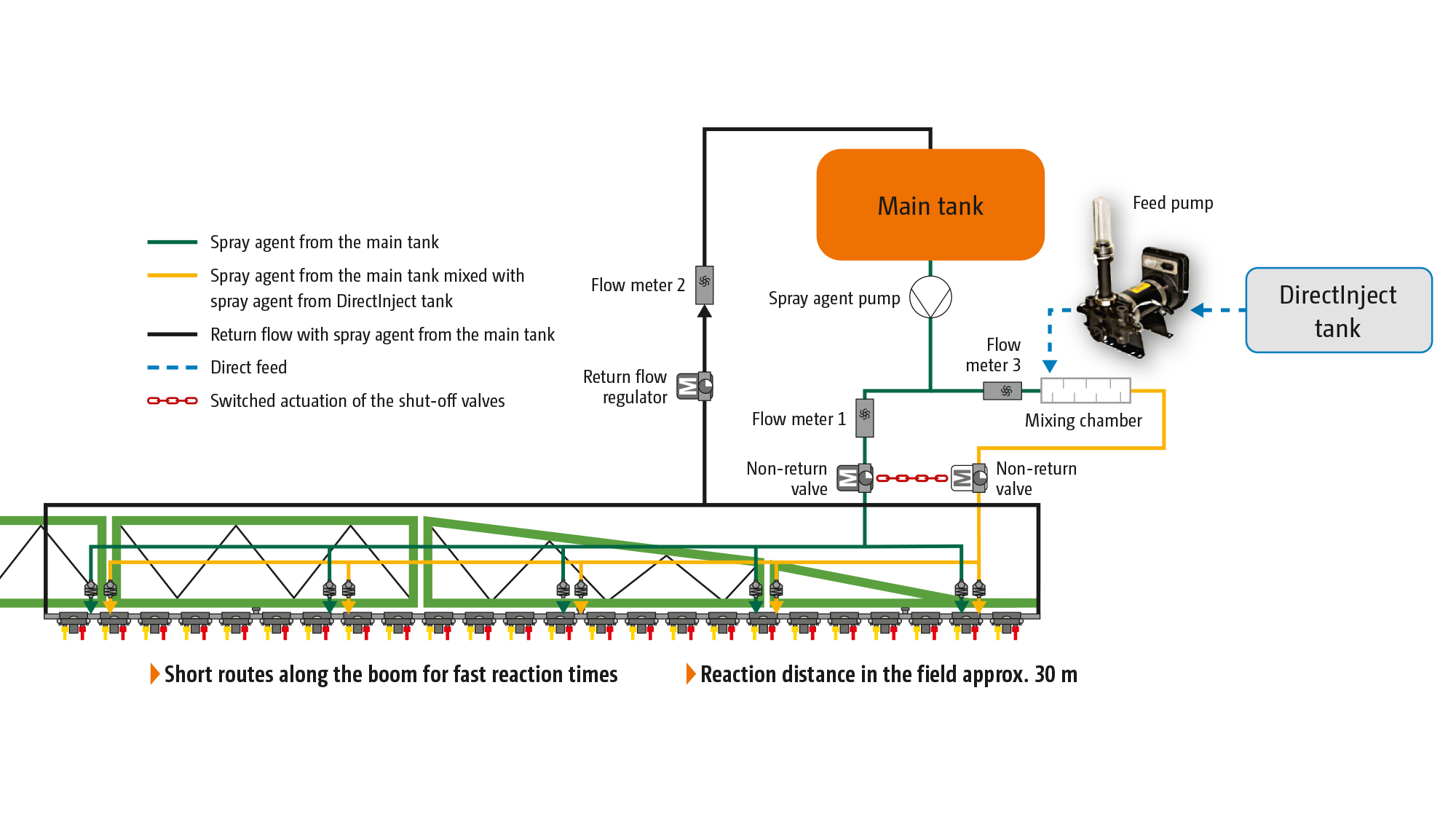

The DirectInject system has enabled AMAZONE to offer a system for the direct injection of plant protection agents which solves, for the first time, the conflicting goals described above. Plant protection agents can be injected or stopped during application as required. The special feature of DirectInject compared to conventional systems is the fast response time of the injection process and its complete integration into the spray agent circuit and operation of the sprayer.

With DirectInject, it is possible to respond individually to the needs of the crop on the field and reduce the use of plant protection agents and the number of additional passes with the sprayer. This saves time, money and protects the environment.

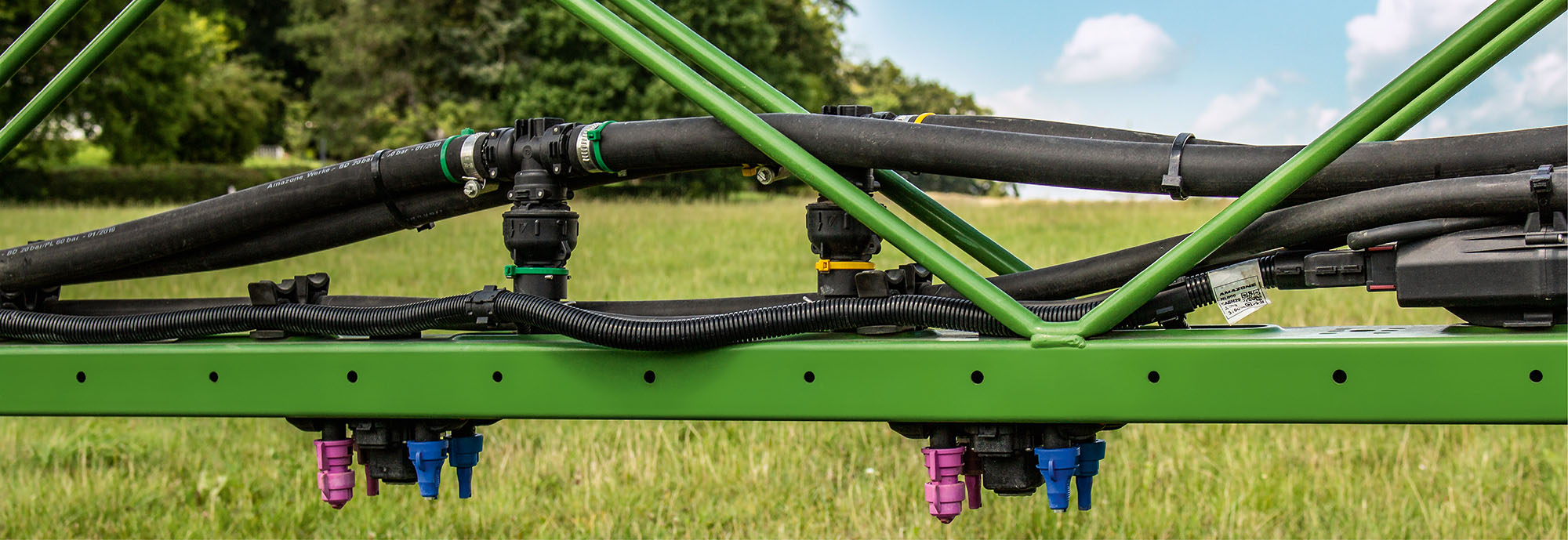

DirectInject consists of an additional 50 l tank with its own metering system, which is integrated into the storage compartment of the UX 01 Super on the right-hand side of the machine. This means that the tank is also easily accessible from the ground and can be filled safely. The integration of these components into the storage compartment also provides optimum protection for all the equipment.

The major advantage of the technology is that DirectInject can work with undiluted plant protection agents. A mechanical agitator ensures that even plant protection agents which tend to separate remain homogeneous.

Application in the field

If the driver of the sprayer notices, for instance, a prevalence of unwanted weeds that need to be controlled in a specific part-area, he or she can activate the metering of DirectInject from the cab at the touch of a button. The supplementary product taken from the DirectInject tank, which is integrated into the storage compartment, is then added to the spray agent from the main spray agent tank in the mixing chamber. The optimised reaction time compared to conventional systems is achieved by a twin-line system. Pre-mixed spray agent from the spray agent tank and the plant protection agent from the DirectInject tank are held in a second spray line in the boom. When the direct feed system is activated, the mixture is applied through the nozzle bodies and nozzles via several injection points in the boom. In this regard, the valve for the spray agent from the main spray agent tank is switched with the valve for the second spray line with the pre-mixed DirectInject agent so that spray agent is always only taken from one line.

These short routes for the spray agent directly in the boom result in short reaction times in the field. The DUS pro high-pressure recirculation system enables the spray agent in the spray line to circulate with the pre-set spray pressure at all times, even when the nozzles are closed. Circulation is stopped when the direct feed system is activated, meaning that the spray agent from the spray agent tank is not mixed with the product from the DirectInject tank.

Residual spray volumes and cleaning

Since DirectInject uses undiluted plant protection agents as the premix in the second spray line, any residual volume not used can be returned to the original container of the product after application. In comparison with conventional systems, the amount of plant protection agent actually needed does not have to be known before application, nor do large mixed residual amounts have to be dealt with afterwards.

The entire system can be cleaned automatically and remotely from the tractor cab after application. All components are integrated in Comfort-Pack plus on the sprayer for this purpose. This gives the user security and saves time.

Farmers who use DirectInject report that they can now react much more flexibly to individual fields and part areas with respect to plant protection. Where differentiated, immediate applications were otherwise not possible, they can now react to the situation in the field in just one pass. Time saved, a reduction in the use of plant protection agents and optimum crops are the result.

The DirectInject direct feed system can be used with the UX 01 single-axle crop protection sprayers with standard ISOBUS communication, Comfort-Pack plus and AmaSwitch or AmaSelect single nozzle control with DUS pro high-pressure recirculation system.

The advantages at a glance:

- Flexible, fast and needs-based use of plant protection agents

- Saving of:

- Working time and labour costs

- Machine costs

- Plant protection agents

- Optimum crops

- Environmentally-friendly

DirectInject direct injection system