The flexible way to optimise yields for rigid and folding models

Many Precea models can be optionally equipped with a hydraulic tramline offset. When the machine is tramlining, the PreTeC coulters, including the fertiliser coulters, are fully automatically pushed together and apart hydraulically without the seed rows being switched off. The seed rate therefore remains constant. As a result, row spacings of up to 115 cm are possible.

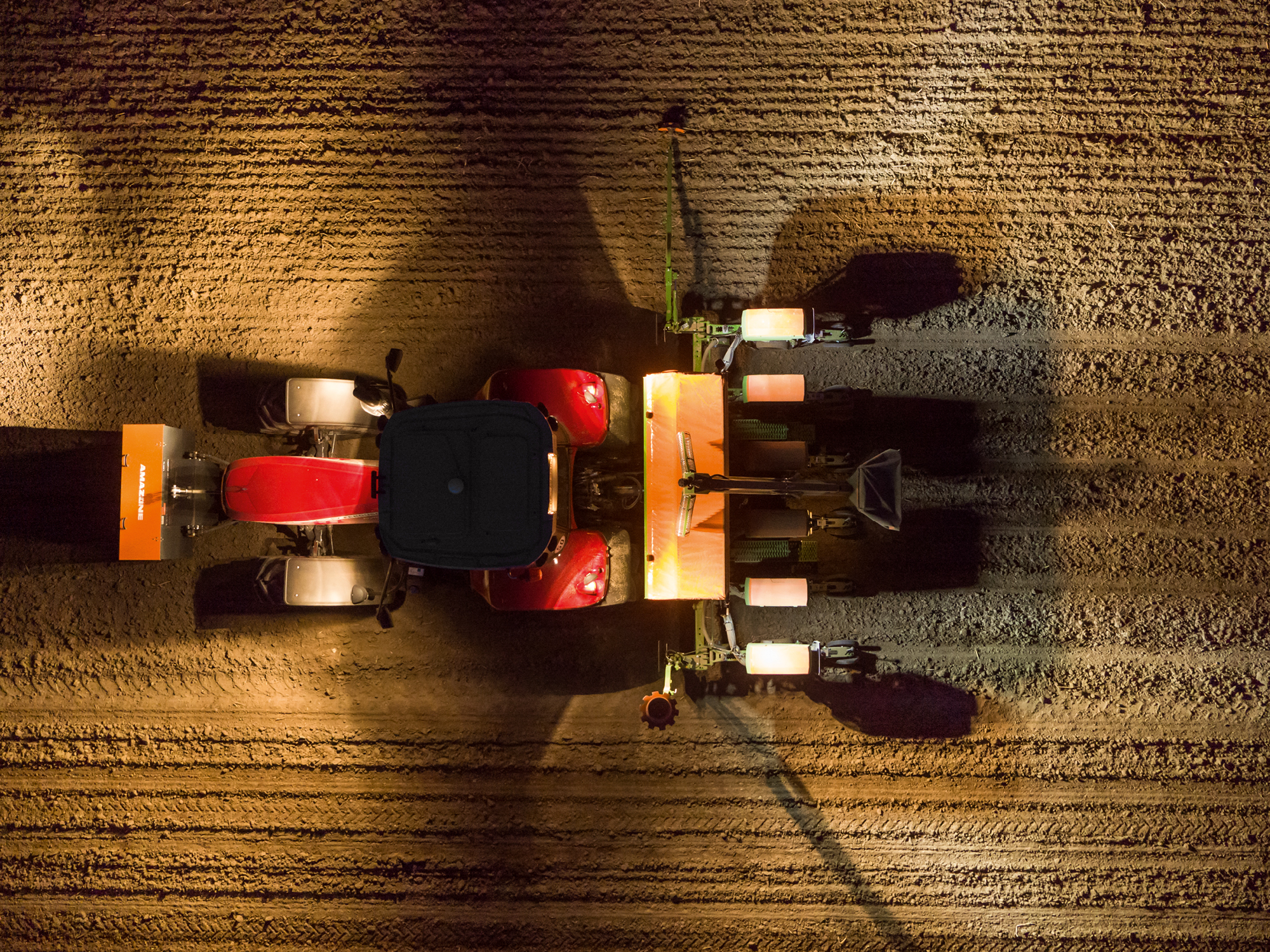

Asymmetric offset of a unit

The asymmetric offset permits track widths up to 2.1 m: 1) Pass 2) Pass

The asymmetric offset actuates just the one cylinder. This means that only one unit is offset. The driver creates one wheel mark in the first pass. The second wheel mark is created in the second pass, so that following crop care machines, such as a crop protection sprayer, do not damage the crop thanks to the row shift.

Your advantages with a hydraulic tramline offset:

- Optimum yield potential since the seed rows do not need to be switched off, they are just offset

- Relief for the driver by automatic detection and adaption to make the tramline

- Lack of plant damage during subsequent working in the crop, as a result of the existing tramline

- Optimum fertiliser supply since the fertiliser coulter and the singling unit are displaced together

Symmetric offset of two units

Symmetric tramline offset on the Precea 6000-2: 1) Pass

When offset symmetrically, the offsetting cylinders are actuated simultaneously on both sides of the machine. A tramline is therefore created in only one pass. The maximum offset distance of a unit is 400 mm. The offset travel can also be reduced if the entire width is not required due to track width or tyre size.

Large row spacing for creating a tramline with an offset unit