Accurate placement of the seed

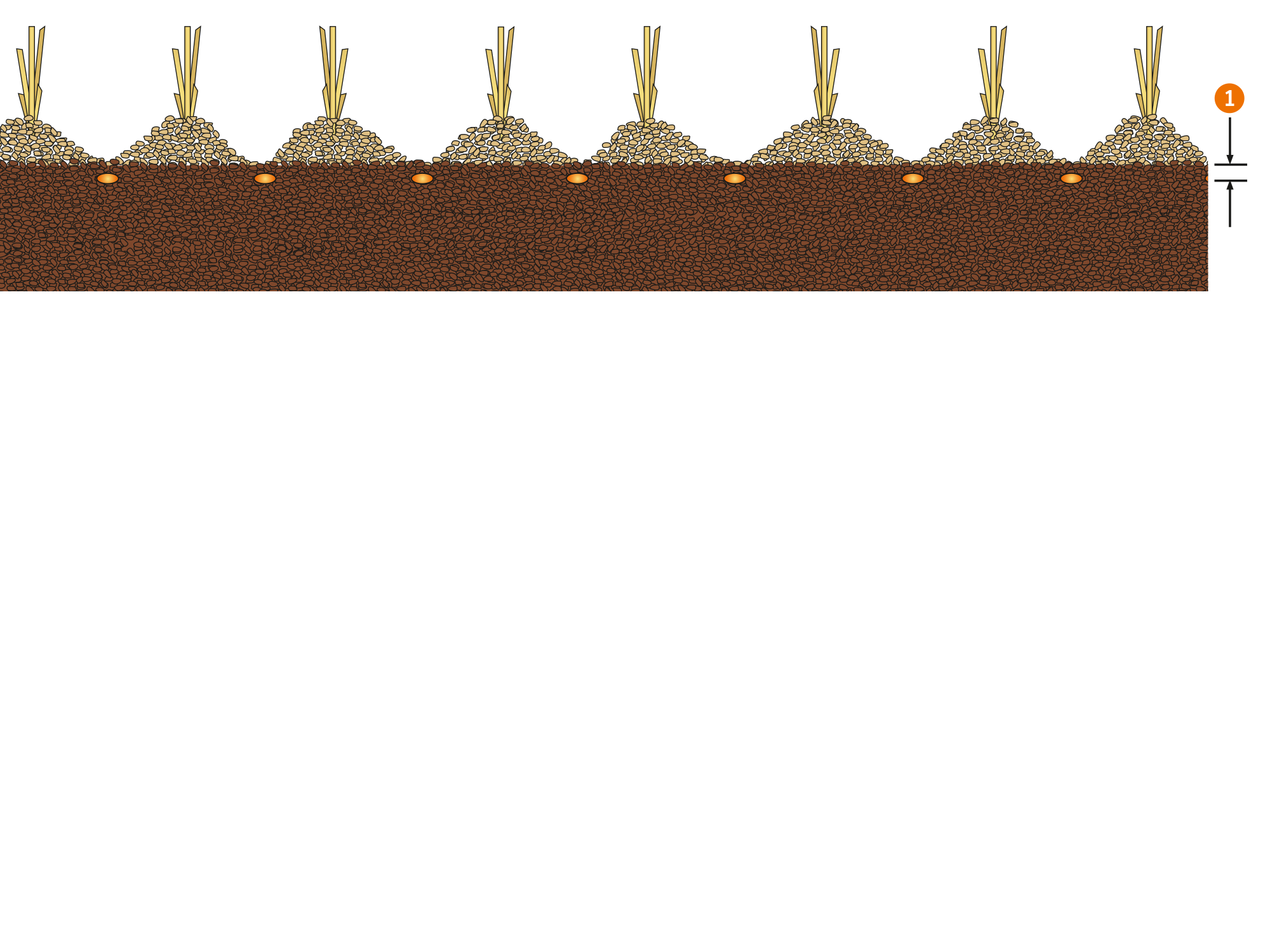

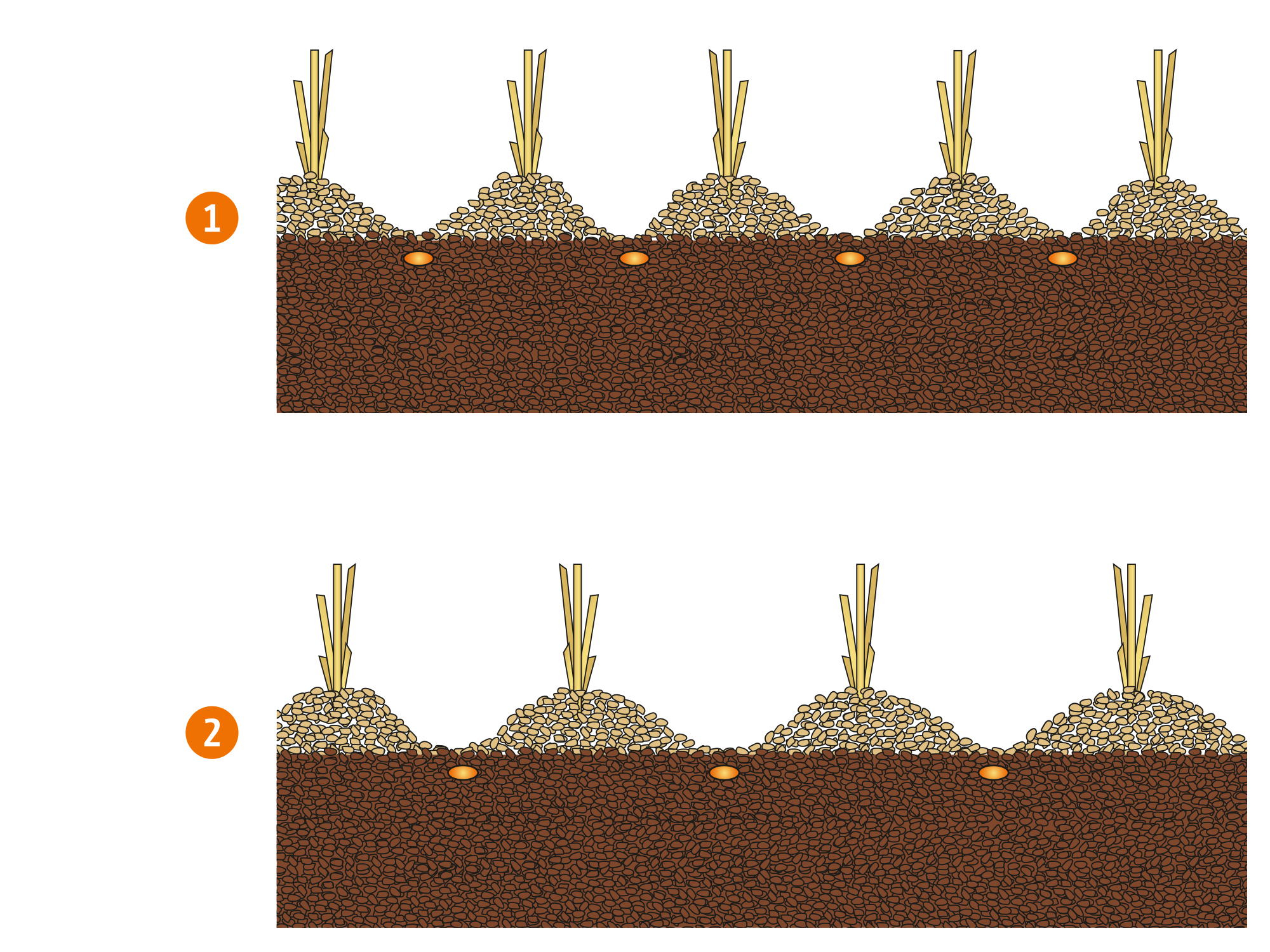

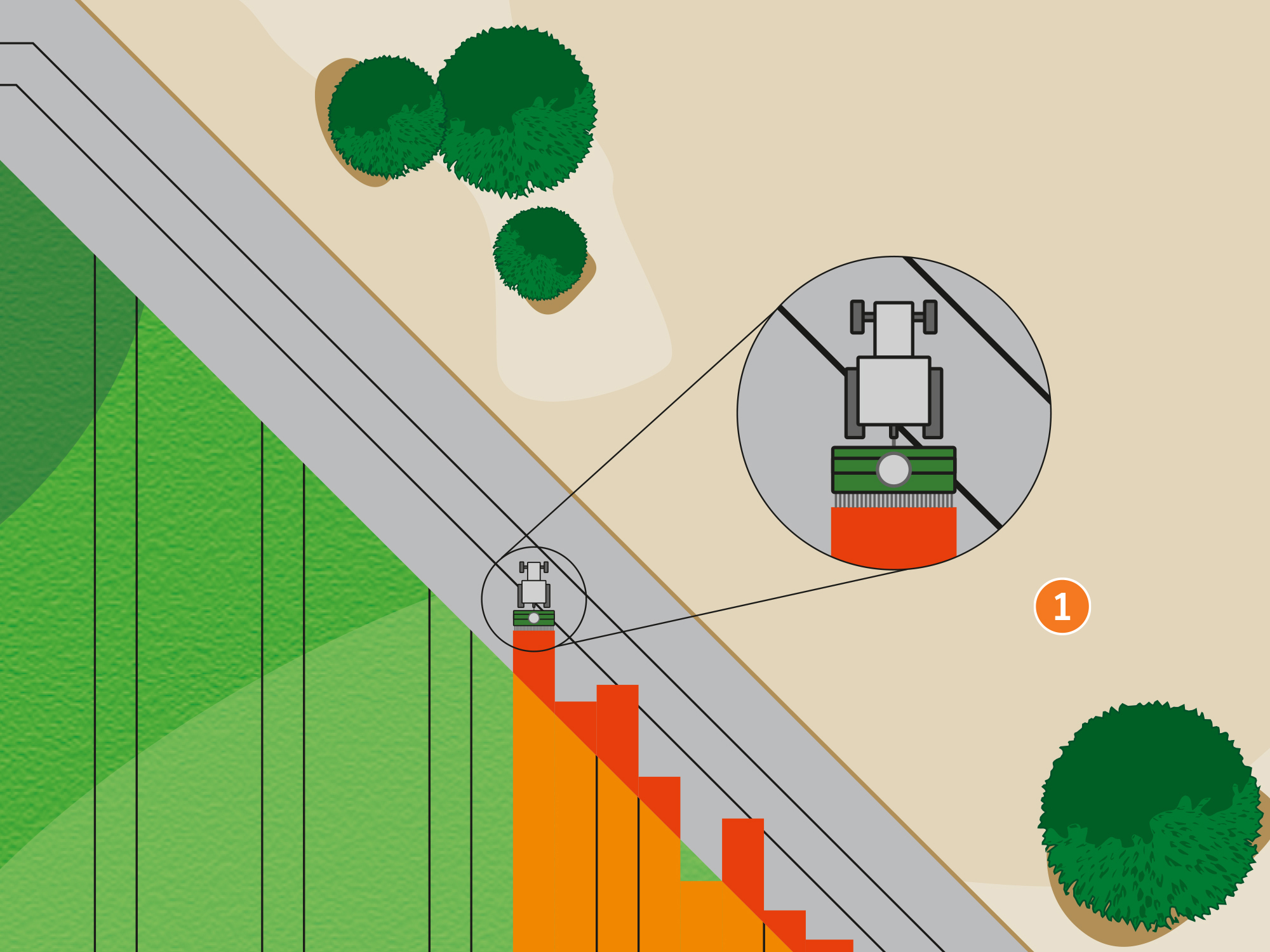

Precise sowing is very important, in order to avoid over- and under-sowing in critical areas. A remedy for accurate placement is offered by the half-side control, which reduces the overall working width to half so that a significant saving is achieved, especially in wedge shaped fields and on the headland. The two halves of the drill each correspond to one controllable part-width section.

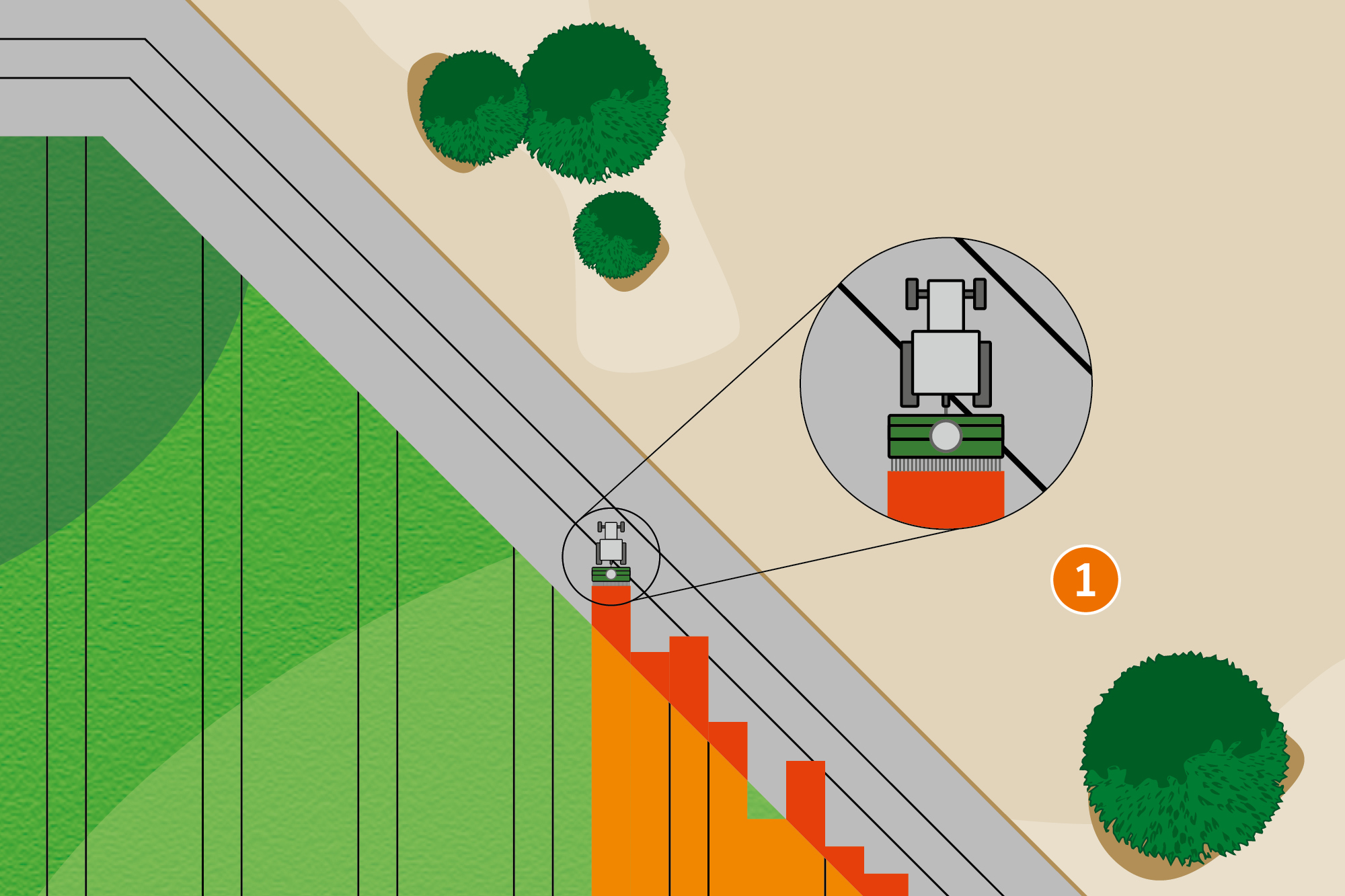

If the operating terminal facilitates Section Control, such as GPS-Switch part-width section control from AMAZONE, the part-width sections are activated completely automatically and in relation to the GPS position. Once a field has been created, and then in automatic mode, the driver can concentrate fully on the operation of the towing vehicle, since the part-width sections are switched automatically in wedge shaped fields and on headlands.

Benefits of automatic part-width section control:

- Stress relief on the driver

- Increase in precision especially at night or at higher speeds

- Fewer overlaps and gaps

- Saving on input costs

- Less crop damage and less environmental pollution

GPS-Switch

With GPS-Switch, AMAZONE offers GPS-based, fully automatic, part-width section control for all AMAZONE operator terminals and ISOBUS-compatible fertiliser spreaders, crop protection sprayers or seed drills.

GPS-Switch basic

- Automatic part-width section control of up to 16 part-width sections

- Creation of virtual headlands

- Automated boom lowering on AMAZONE crop protection sprayers

- Optional with AmaTron 4

GPS-Switch pro (as an extension of GPS-Switch basic)

- Automatic part-width section control with up to 128 part-width sections, in particular for crop protection sprayers with individual nozzle control

- Marking obstacles (e.g. water holes, pylons)

- Auto-zoom when approaching the headland

- Optional with AmaTron 4

- Virtual headland

- Field application maps for different seed rates are also possible

- Worked area

- With half-side shut-off

- The seeder automatically switches off precisely