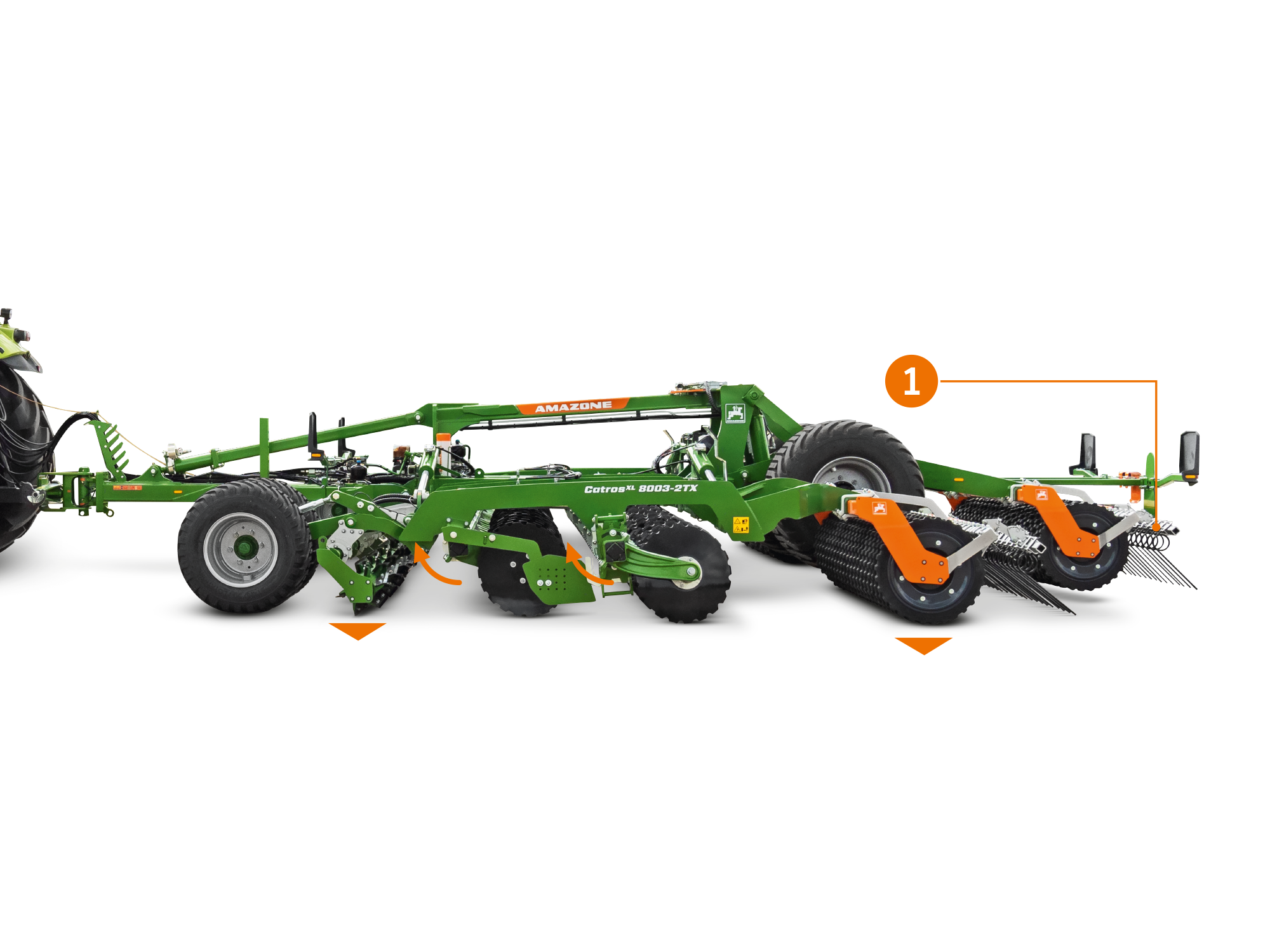

1. Easy depth adjustment of the base machine

Models in the Catros 03 series feature a unique of working depth adjustment concept. The roller has a fixed connection with the main frame. The two rows of discs are completely rotated to adjust the working depth.

- Comfortable working depth adjustment, as the main frame remains in the same position.

- Blockage-free in extreme conditions. Turning the rows of discs leaves more space between the discs and the frame and roller.

2. Flexible working depth adjustment of the front tools

AMAZONE offers the right tool combination for all conditions with a wide selection of front tools.

- Independent adjustment of the front tool and the disc

- Independent adjustment of the front tool and the disc in relation to the frame

3. Independent depth of the roller and the rear harrow

With more than 10 different rollers and therefore probably the widest roller range on the market, AMAZONE offers the ideal roller for every soil type. The various rollers ensure optimum reconsolidation according to individual requirements. The working depth of the roller is independent of the working depth of the discs, so there is no need for time-consuming setting and adjustment of the height!