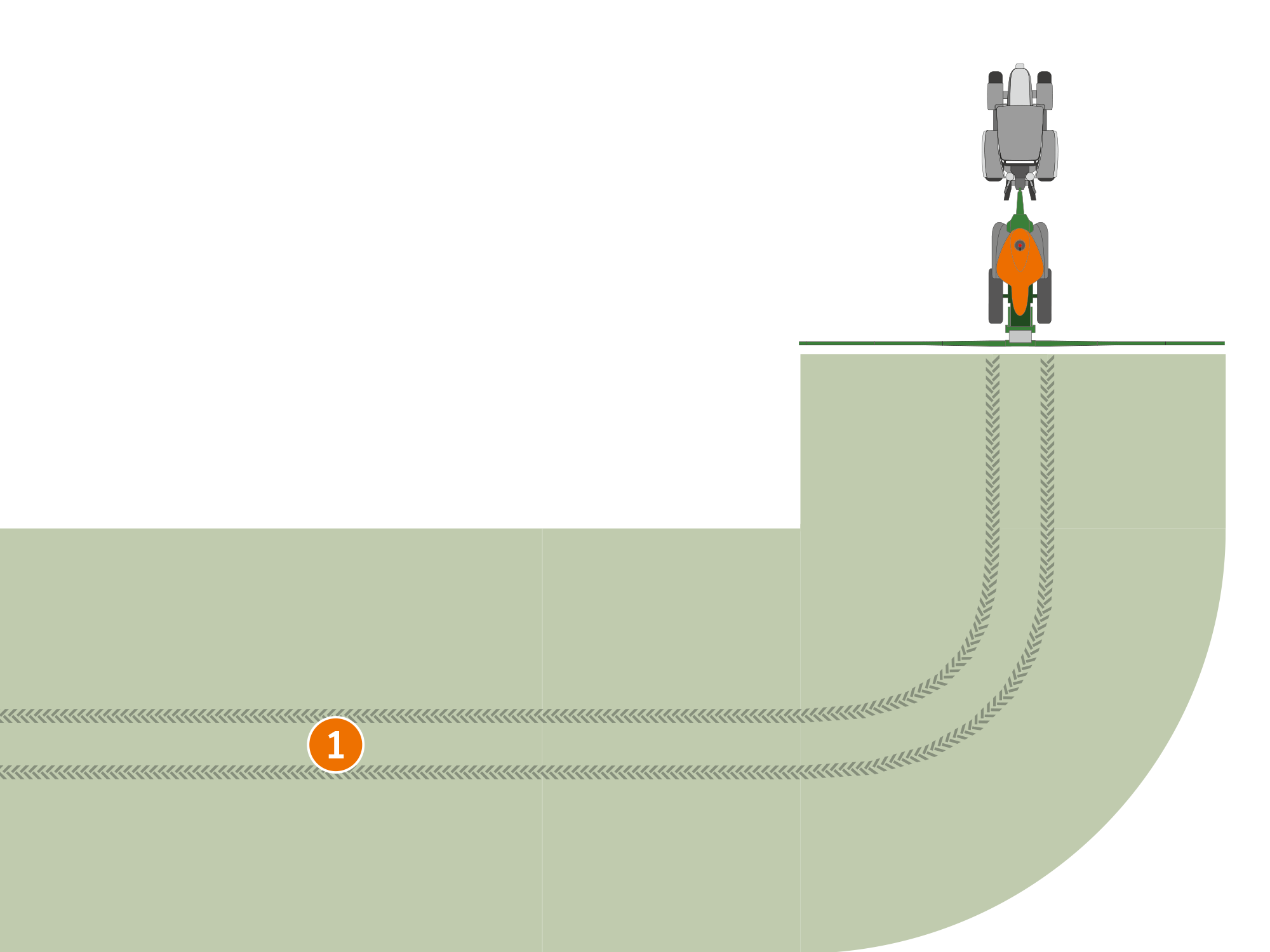

Over- and under-dosing when negotiating bends

In the past, the distribution of plant protection products when driving round bends has led to an over-application on the inside of the bend and an under-application on the outside of the bend. The problem increases with increasing boom widths. Over-applying on the inside of the boom must be viewed more critically, as potential overdose levels of more than 300% are possible.

In addition to the nozzle pressure, AmaSelect CurveControl uses sensors to determine the curve radius and automatically calculates the pressure adjustment for the changed flow rate. The system then balances the application rate in the boom independently of the part-width section by means of automatic nozzle changing in the boom.

The benefits:

- Virtually uniform application rates when negotiating bends over the entire working width

- Optimum crop management

- Prevention of resistance caused by under-dosing