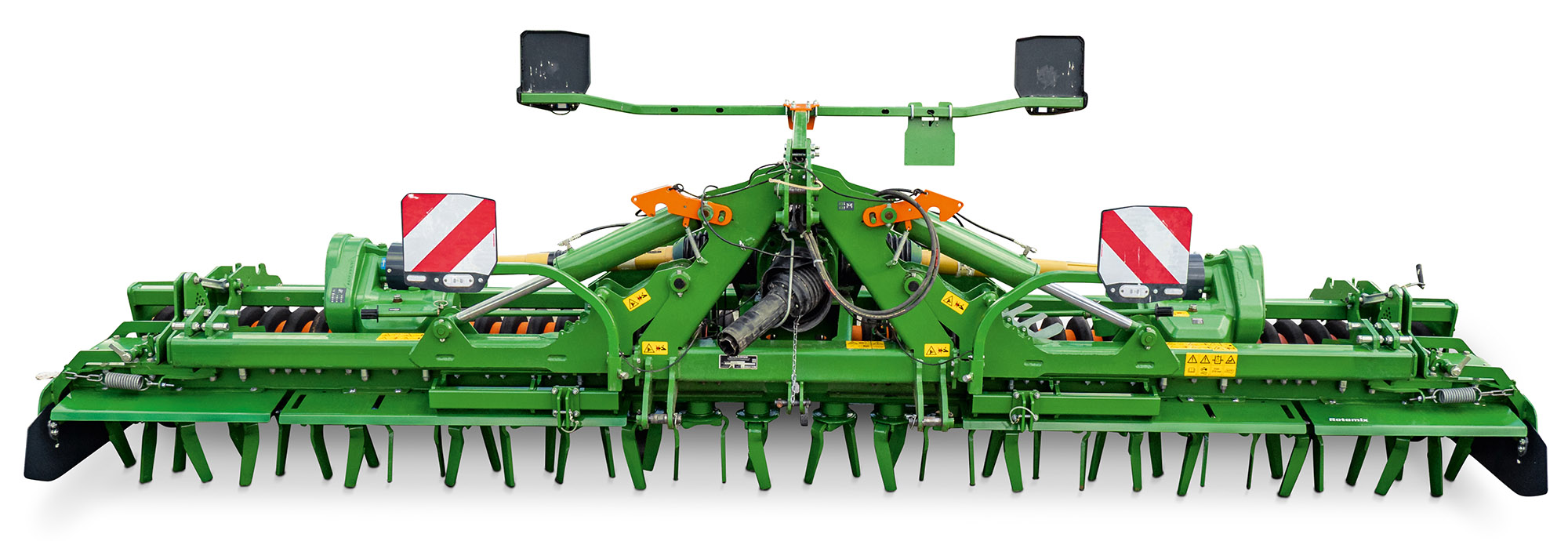

KE 02 Rotamix rotary harrows

New: working widths of 4.5 m and 6 m

Extended rotary harrow range for use with the Avant seed rail or PreTeC sowing units

AMAZONE has extended its range of new KE 02 Rotamix rotary harrows with the addition of 3 folding variants. The rotary harrows, with working widths of 4.5 and 6 metres are suitable for tractor classes from 300 to 400 hp. The rotary harrows are characterised in particular by their high output and by their very good crumbling and soil levelling effect.

High work rates

The tool carriers on the KE 02-2 Rotamix are fitted with trailing tines. The Rotamix principle, with 4 tine carriers per metre of working width, reliably levels the soil, leaving a good crumb structure.

With the 4.5 m and 6.0 m wide rotary harrows, AMAZONE is offering new models that have been developed primarily for large work rates. The rotary harrow is very efficient, thanks to its working width of up to 6 m. Quick folding to the 3 m transport width also ensures rapid and safe transport between fields.

Rotamix system - short, compact and 4 more tool carriers at a working width of 6 m

The KE 4502-2-300, KE 6002-2-300 and the KE 6002-2-400 rotary harrows with the Rotamix system have four tool carriers per metre of working width over which the incoming power is distributed. The trailing tines produce a very good crumb structure, even on heavy soils. The new rotary harrows are therefore very well suited for seedbed preparation, particularly following the plough.

The number of tine carriers permits the use of a smaller spur gear diameter. This layout means that a very compact and light design of the robust rotary harrow trough is possible. This compact arrangement ensures that the leverage effect on the tractor is reduced, therefore having less lifting power requirement than other rotary harrows.

When worn, the 290 mm long KE "trailing" tines can be easily replaced, and without tools, using the Quick+Safe quick change tine system. Each half of the machine is protected against overload on the tines via a ratchet clutch.

A higher class of performance with the DirectDrive gearbox

The centrepiece of these new models of rotary harrow is the DirectDrive gearbox, which ensures a long service life and maximum smoothness in work. The double sealing for the rotors, with cassette seal and labyrinth seal, protects against dust, moisture and dirt ingress.

The DirectDrive gearbox transmits the higher power directly to the spur gears on the tool carriers. On the new KE 4502-2-300, the KE 6002-2-300 and the 6002-2-400 Rotamix there is no redirection of the power thus ensuring excellent low-wear power transmission. A gearbox is mounted to both side wings in each case. The rotary harrow can be used with a PTO speed of 1000 rpm. Exchange gear kits enable the tool carrier speed to be adapted to different soil conditions.

Settings and options

For a precise and consistent working depth, the KE 02-2 is adjusted using a series of holes. This facilitates a very broad setting spectrum where the working depth can also be adjusted mechanically and very precisely via a depth block. The setting is designed to be simple and easily understandable for the operator.

The height of the levelling board for levelling the soil is precisely guided by the roller. The levelling board also deflects upwards thanks to the integrated overload protection. A universal setting tool is supplied for fine-tuning the required settings, which can also be used across many other tasks, such height adjustment of the side plates and for setting the track markers.

The levelling board is shortened by 100 mm for improved soil passage and for better levelling of the soil. This improves the throughput between the side plates and levelling board.

Can also be used in conjunction with a seed rail or singling units

The KE 4502-2-300 rotary harrow can be equipped with the Avant's RoTeC seed rail with 36 RoTeC single disc coulters on12.5 cm spacing. Alternatively, 6 PreTeC sowing units can be mounted with a row spacing of 75 cm for precision seeding.

The KE 6000-2-300 and KE-6000-2-400 rotary harrows and further KE models can be equipped, via a linkage, with either the RoTeC single disc or the TwinTeC double disc seed rails with a choice of row spacings of either 12.5 and 15 cm.

Wide range of rollers provides for good reconsolidation across all soils.

Numerous roller types with different diameters for targeted reconsolidation are available for a wide range of site-specific requirements.

The lightest packer roller is the cage roller. This roller is suitable for solo use of the rotary harrows. The harrow is guided reliably at depth by the packer roller.

For full-width crumbling and reconsolidation, AMAZONE offers a packer roller. With a diameter of either 500 or 600 mm, the roller is also ideal for carrying the rotary harrow in conjunction with a seed drill.

The wedge ring roller, with diameters of 520, 580 or 600 mm, is ideal for light to medium soil types and offers strip-wise reconsolidation of the soil exactly in line with the sowing coulter. Optionally, the wedge ring roller can also be fitted with a matrix profile tyre for an even better self-drive effect in lighter soils. These rollers are also ideal for use with a seed rail. Even when being used in solo operation, they leave well reconsolidated soil, with loose strips that permit a better interchange of air and water.

The roller programme is rounded off by the trapezium ring roller with a diameter of either 500 or 600 mm. These packers are also suitable for reconsolidation in strips.

- Efficient flexible use of the rotary harrows

- Convenient change between precision seeding and cereal drilling

- Simple operation, even when used in combination with other AMAZONE implements

Gallery