Sep 12, 2023

New functions for the AmaTron 4 ISOBUS terminal

5 software functions for new possibilities within Precision Farming

The AmaTron 4 ISOBUS terminal was specially developed by AMAZONE and is used for monitoring and operating AMAZONE ISOBUS machinery as well as the ISOBUS machinery of other manufacturers. AmaTron 4 has been exceptionally well received since its launch onto the market in 2018 especially as a result of its practice-oriented and clearly arranged menu prompting, which offers the user comfortable and intuitive operation at all times. Special software functions for AmaTron 4 are a highlight. At AMAZONE, "More than ISOBUS" stands for special terminal and machine functions which offer the user added value in the precision farming sector. Well-known functions with a unique selling point which are made possible in combination with AmaTron 4 as an ISOBUS terminal, include the HeadlandControl headland management system as well as the parabolic switching characteristic with an AMAZONE ZA-TS fertiliser spreader or automatic boom lowering with an AMAZONE crop protection sprayer. The latest software of AmaTron 4 now offers even more additional functions in combination with AMAZONE crop protection sprayers, seed drills, fertiliser spreaders and for data management.

Processing of spot application maps – AmaSelect spot

Weeds are spread heterogeneously over the field and can often be found either in patches or in strips. With AmaSelect individual nozzle control, AMAZONE has offered an option for part-area, site-specific weed treatment based on highly accurate spot application maps since 2019. To begin with, the area to be treated and its weed distribution is scanned via a service provider and the data processed to create a spot application map. In the second step, weeds are spot-treated across the surface area.

These point or multipoint maps can now be comfortably loaded into the terminal via the AmaTron 4 Import menu. When passing over the area, AmaSelect spot opens the nozzles exclusively at the points marked on the application map, so that only the previously analysed weeds are treated. This enables very precise spot application on the weeds and provides potential savings on plant protection agents of up to 80 %, depending on the weed cover. This protects the environment and also prevents the development of resistance thanks to small-area spot applications with a 100 % concentration of plant protection agent. The application is particularly comfortable for the driver when the AmaTron Twin App for AmaTron 4 is used. The driver has both the machine operation menu and the map view with the spot areas in sight at all times here.

In advance with pinpoint accuracy with DirectInject

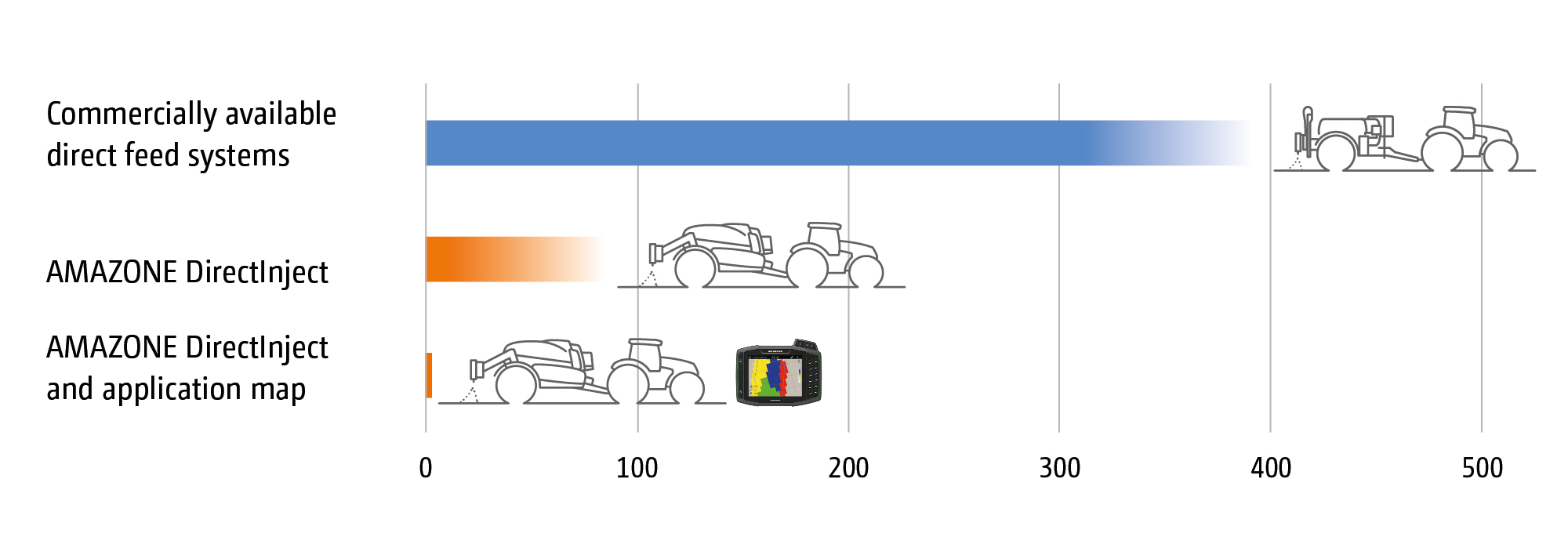

The DirectInject system from AMAZONE enables the needs-based supply of plant protection agents during the application, so that specific products and agents are only applied in patches or to individual areas. With DirectInject, it is possible to respond individually to the needs of the crop on the field and reduce the use of plant protection agents and the number of additional passes with the sprayer. The well-known special features of this system include complete integration in the spray agent circuit, ISOBUS control of the sprayer and the extremely short response time.

The possibility of metering the additional agent in advance with pinpoint accuracy by means of application maps has now been added. The spray rate of both the agent in the main tank and the agent from the direct feed system can be automatically regulated. The DirectInject agent is pre-metered before arrival in the treatment zone and is immediately available on reaching the zone. The route function from GPS ScenarioControl, which represents an add-on for AmaTron 4 in combination with the AmaTron Twin App, is used to provide an accurate forecast. It is known which application areas will be passed through next because of the route stored in the scenario and knowledge of the area already treated. This provides optimum small-scale treatment with extremely high precision.

MultiMap – part-area, site-specific application for any medium

The application of more than one medium has become commonplace, especially during sowing. The use of several hoppers enables the application of not only seed but also fertiliser, micro-granules, a companion crop or undersown crops at the same time during the same pass. Since the soil conditions, water availability and therefore also the yield potential can sometimes vary greatly within a field, it makes sense to tailor seed and fertiliser rates to these conditions.

The MultiMap function is a component of the AmaTron 4 terminal licence GPS-Maps&Doc and enables the applied materials to be regulated independently of each other via application maps, so that they are applied on a part-area, site-specific basis. In addition to part-area, site-specific sowing and fertilisation, the coulter pressure can also be regulated depending on the soil quality based on a soil texture map. Variable soil conditions are compensated for and an even seed placement is obtained. AmaTron 4 allows the simultaneous processing of up to 4 application maps. As a result, nothing stands in the way of farming practice adapted to local conditions.

GPS ScenarioControl for the automation of recurring work steps

When applying fertiliser, drivers have to juggle various tasks. Tasks which are mostly repeated on the field, from fertiliser application to fertiliser application as well as from year to year. This concerns driving and turning in the field on the one hand and the activation and deactivation as well as the selection of the correct border spreading modes and HeadlandControl on the other. These are work steps where drivers have to make a decision and mistakes are the order of the day, especially in the case of inexperienced drivers or drivers unfamiliar with the area.

With GPS ScenarioControl, the route and border spreading modes are recorded and geo-referenced on a one-off basis and automatically replayed during subsequent applications to assist the driver. GPS ScenarioControl is an additional application for the AmaTron 4 ISOBUS terminal and can be viewed and operated via the AmaTron Twin display extension. In the AmaTron Twin App, the route is clearly displayed to the driver and the stored border spreading setting is automatically activated or deactivated on passing a switch point. This ensures error-free and legally-compliant fertiliser application as well as making the work easier.

Furthermore, the route function is not restricted to the fertiliser application but can be used with any desired connected implement. Once stored in the scenario, the route can also be used, for example, for the application of plant protection agents, thereby ensuring the same routes in the field at all times and preventing the flattening of crops by taking wrong turns in tramlines. Combined with the use of application maps, the route function enables spot-accurate metering of the additional agent.

Sharing job data from AmaTron 4 via smartphone

If job data is to be used in AmaTron 4, in order, for instance, to carry out part-area, site-specific application, there are various ways of importing it to the terminal and exporting it after work has been completed for the purposes of documentation. The usual method is to insert a USB stick in the AmaTron 4, so that jobs can be exchanged. AmaTron 4 is able to process job data in both ISO-XML format and from a Shape file. An ISO-XML TaskSet can be exported for the purposes of documentation or a PDF export of the work can be easily and comfortably created and saved on the USB stick. The PDF export can be viewed on the computer and saved or printed out.

AMAZONE has now made data exchange with AmaTron 4 even simpler, with the result that job data can be sent easily and comfortably to the AmaTron 4 via a smartphone and also accessed by the AmaTron 4. This sharing function is already known from smartphone use and is enabled via the myAmaRouter App. Both ISO-XML and Shape files can be shared from email services and standard messenger services and transferred directly to the AmaTron 4. This function also allows completed jobs in AmaTron 4 to be exported from the terminal in ISO-XML or pdf format and shared as desired via a smartphone. This further facilitates data exchange and ensures a high degree of flexibility between the map creator (e.g. farm manager) and the driver.

- AmaTron 4 ISOBUS terminal offers 5 innovative additional functions for precision farming

- Comfortable and precise cultivation of part-areas down to the individual plant

- Reduced workload and more flexibility through simplified digital data management and automated switching operations

- Optimised and resource-conserving use of inputs

New functions for the AmaTron 4 ISOBUS terminal