WindControl – don’t give wind a chance!

Optimum lateral distribution

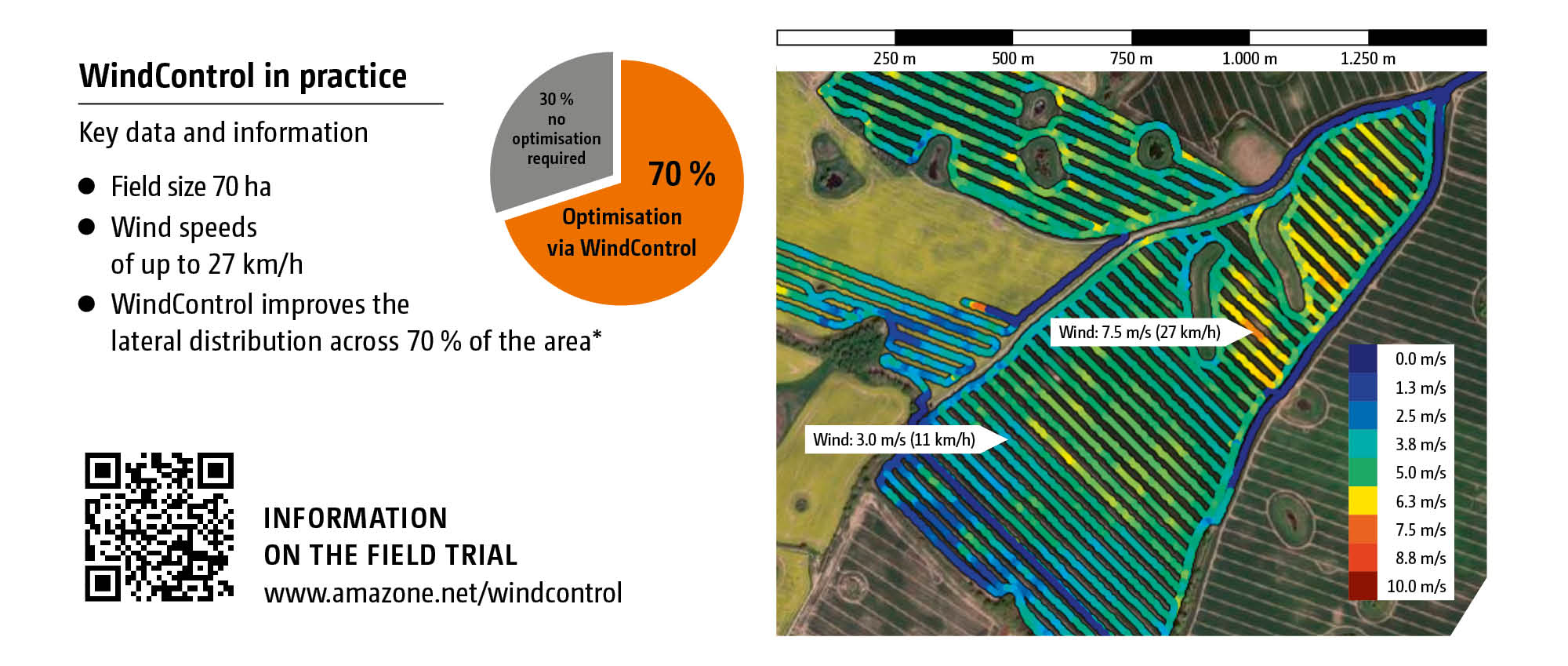

The wind is always blowing somewhere in the world and this represents a major challenge in maintaining an even fertiliser spread pattern. The influence of wind on the spread pattern can be constantly monitored and automatically compensated for with the AMAZONE WindControl system (according to Prof. Dr. Karl Wild of the University of Applied Sciences, Dresden).

Mounted on the machine, a high frequency measuring wind sensor, registers both the wind speed and also the wind direction. According to this data, the job computer then calculates new settings for the delivery system and the spreading disc speed. In a cross wind, the disc speed is increased on the side into the wind and the delivery system is rotated outwards. At the same time, the speed of the downwind side is reduced and the delivery system rotated inwards.

With the aid of WindControl, larger time windows are created for spreading even where there is an influence of wind. Apart from all the important fertiliser spreader parameters, the user additionally always has, in view, the real-time direction of the wind, the force of wind and if the wind is gusting. In addition, in heavy winds, when the system is no longer able to compensate for, or when the wind gusts are too frequent, WindControl sends an automatic alarm to the driver.

The benefits

- Higher output through longer windows of use

- Increased yield through optimised lateral distribution

- Operational safety via the automatic warning system