HeadlandControl – optimum lateral distribution on the headland

The problem: Over- and under-fertilisation on the headland

The AutoTS border spreading system makes it possible for the operator to reliably generate a very steep cut-off to the border spread pattern and thus create the perfect growing conditions right up against the field edge. Compared to other border spreading systems, a significant increase in yield is possible.

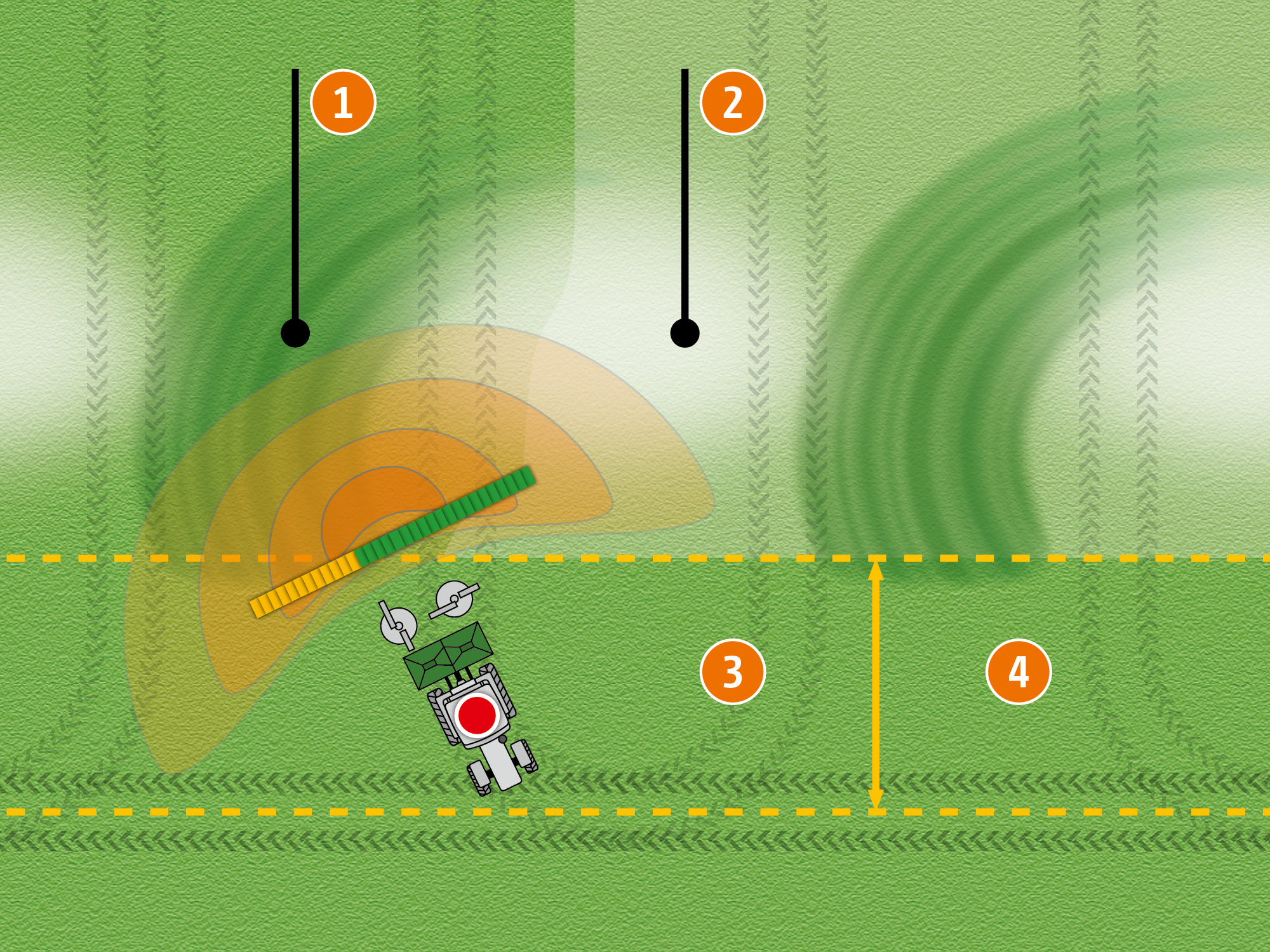

Switch-off time on the headland: Without HeadlandControl

- Spreader switches off too late and is already turning

- Tractor would have to drive beyond the headland tramline

Result: Over- and under-fertilised zones are created

- Over-fertilisation (dark-green)

- Under-fertilisation (white)

- Standard headland

- Inner throwing distance without HeadlandControl

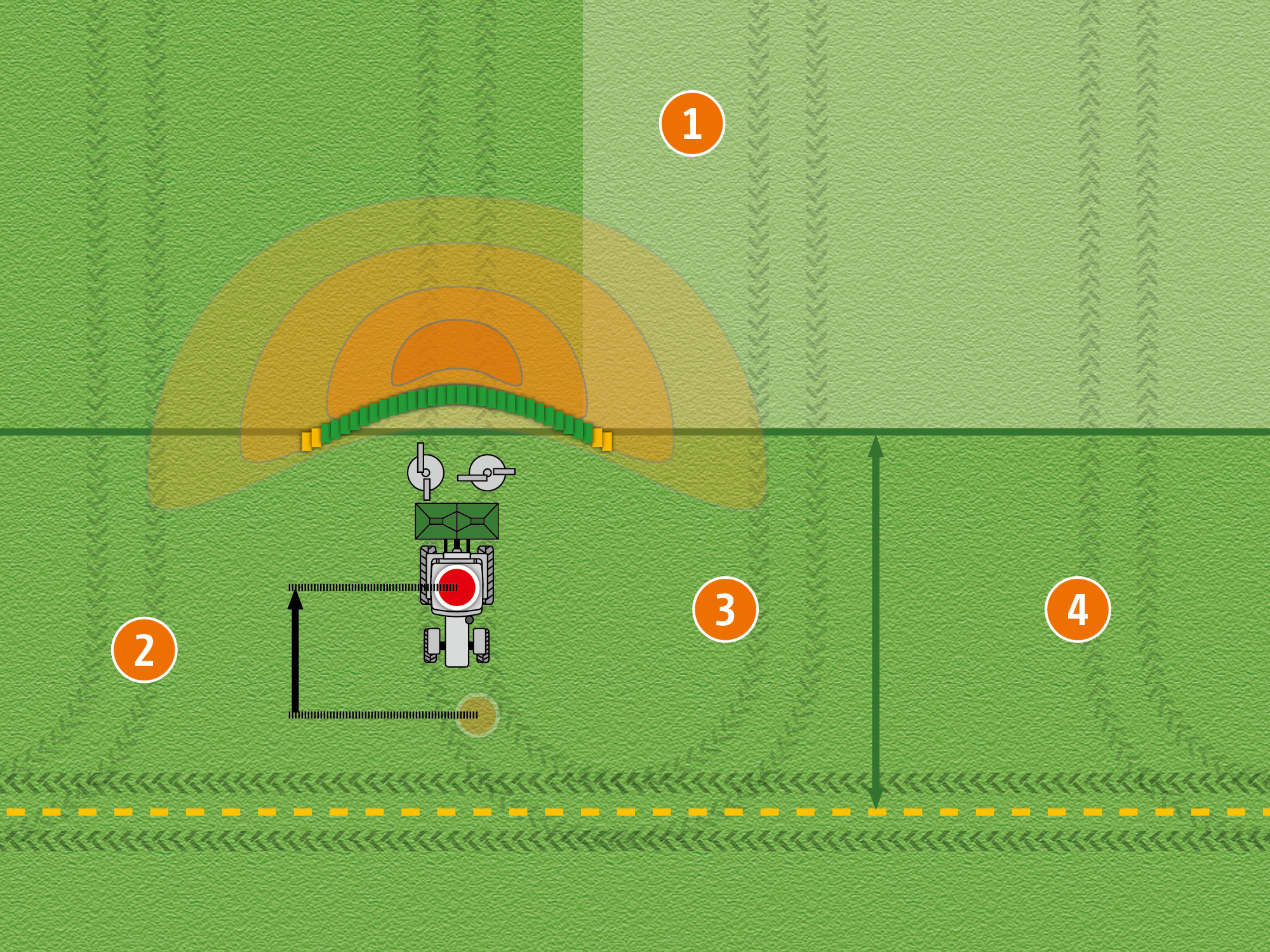

The solution: HeadlandControl

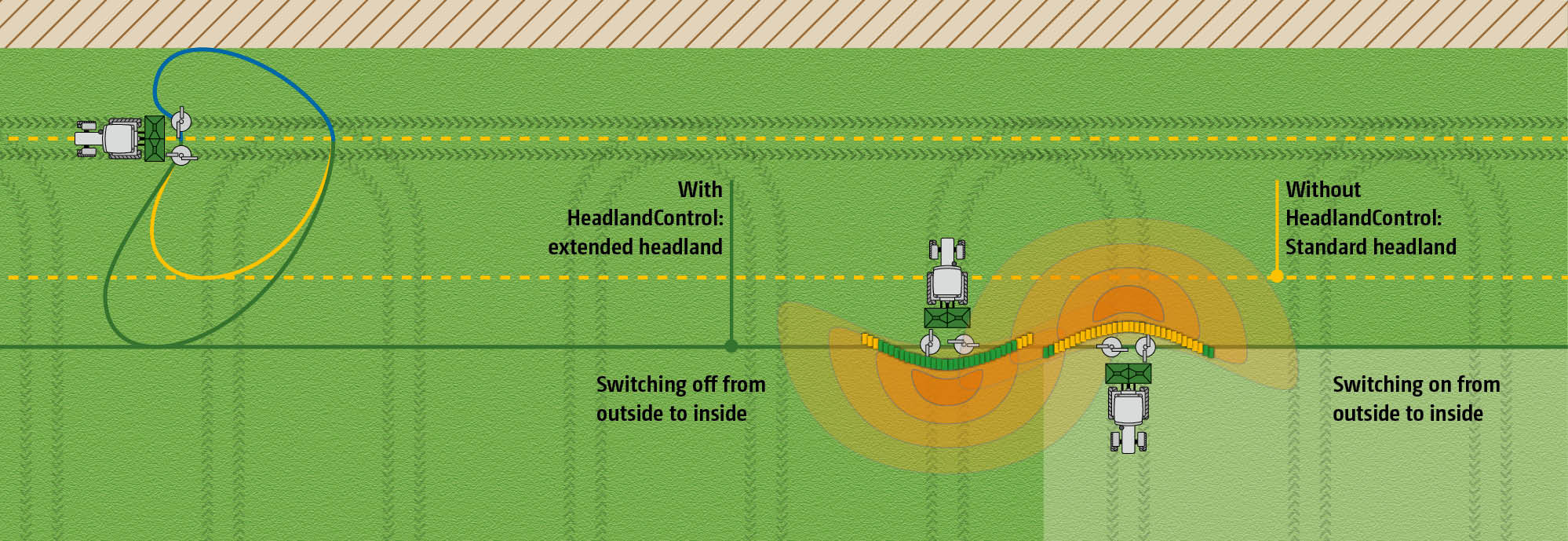

When HeadlandControl is activated, the throwing width and spread rate are increased on the field side, so that the switch-off point is moved towards the inside of the field. Furthermore, the new part-width section control, which is now adapted to the shape of the spread fan, causes the part-width sections to be switched off from the outside to the inside when entering the headland. Over- and under-fertilised zones on the headland are subsequently avoided.

With HeadlandControl

- HeadlandControl means that the spreader continues to apply fertiliser to the crop when it is on the headland

- The tractor can follow the wheel tracks of the sprayer

Result: Uniform crops across the headland

- Improved lateral distribution at the headland

- Switch-off point moved

- Extended headland

- Inner throwing distance with HeadlandControl