AutoTS – comfortable and precise lateral distribution right up to the field boundary

Via the disc-integrated AutoTS border spreading system, the different border spreading techniques can be activated– border or water course spreading – comfortably via the terminal in the tractor cab and irrespective of which side.

AutoTS - the ingenious principle

A setting motor twists the carrier vane forwards by approximately 10 ° so that, when border or watercourse spreading, the fertiliser is delivered via the shorter border spreading vanes. Due to the combination of disc speed and a shorter vane, the fertiliser is thrown over a significant shorter distance without affecting it mechanically.

Effective and precise – spread only where the fertiliser will benefit plant development

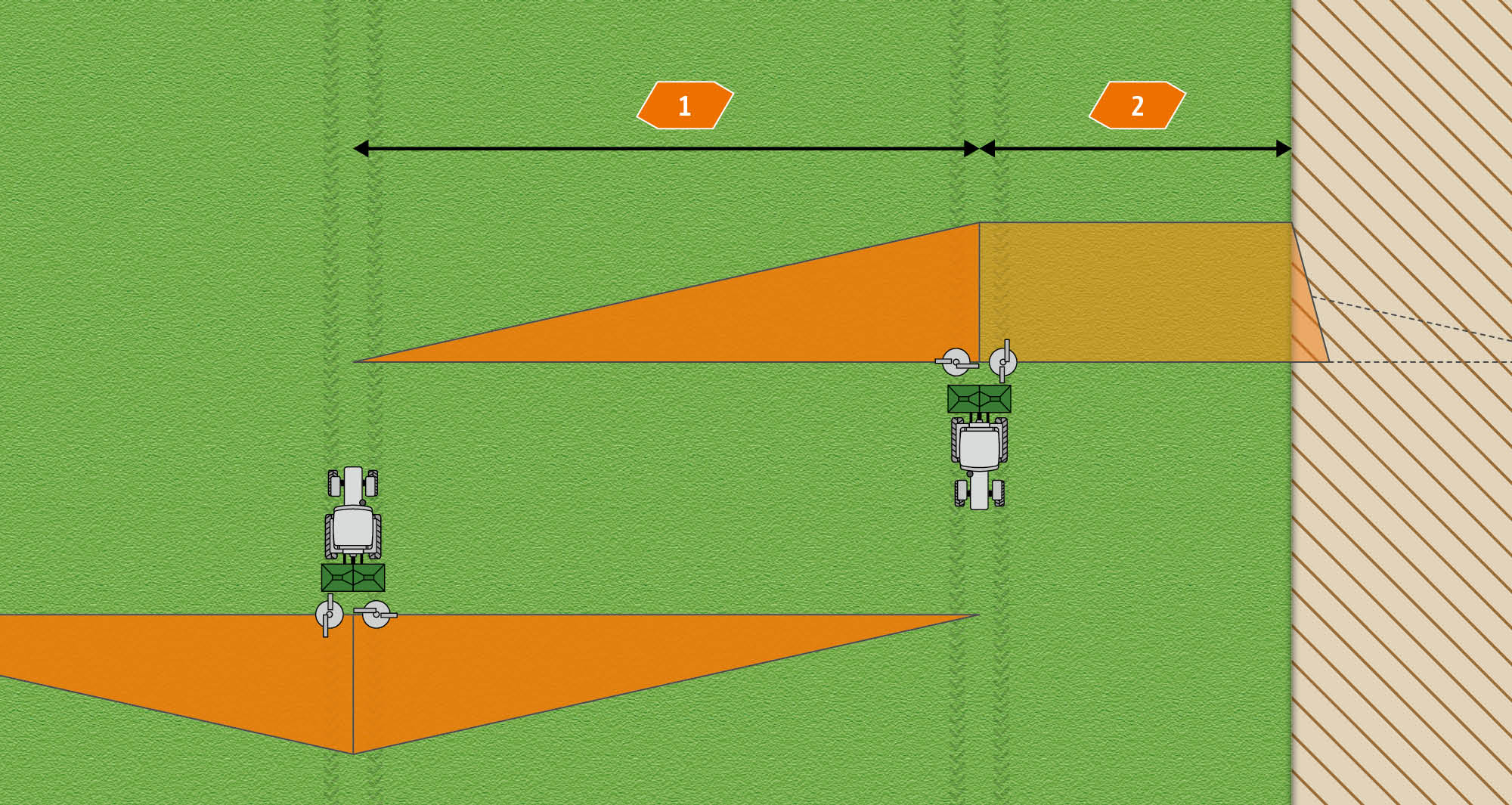

Side spreading (yield-oriented setting)

The adjacent field is an area which is used agriculturally. In this case it is tolerable for a small quantity of fertiliser to be thrown over the field boundary. The full target rate is applied right up to the field boundary.

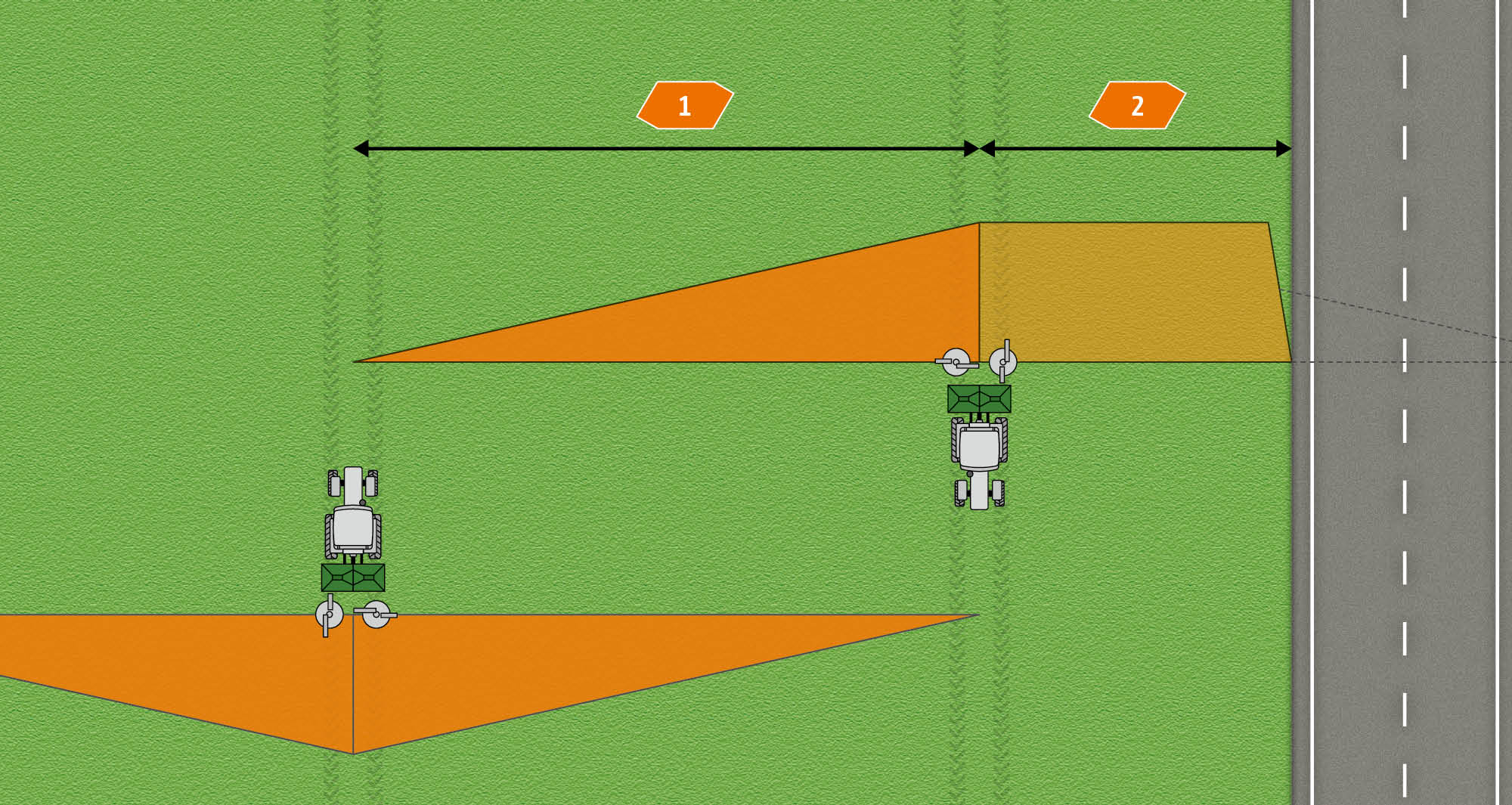

Border spreading (environmentally oriented setting)

If the field is next to a road or a cycle path, no fertiliser may be thrown beyond the field boundary. In this case, the throwing distance is adjusted in combination with the shutter slide.

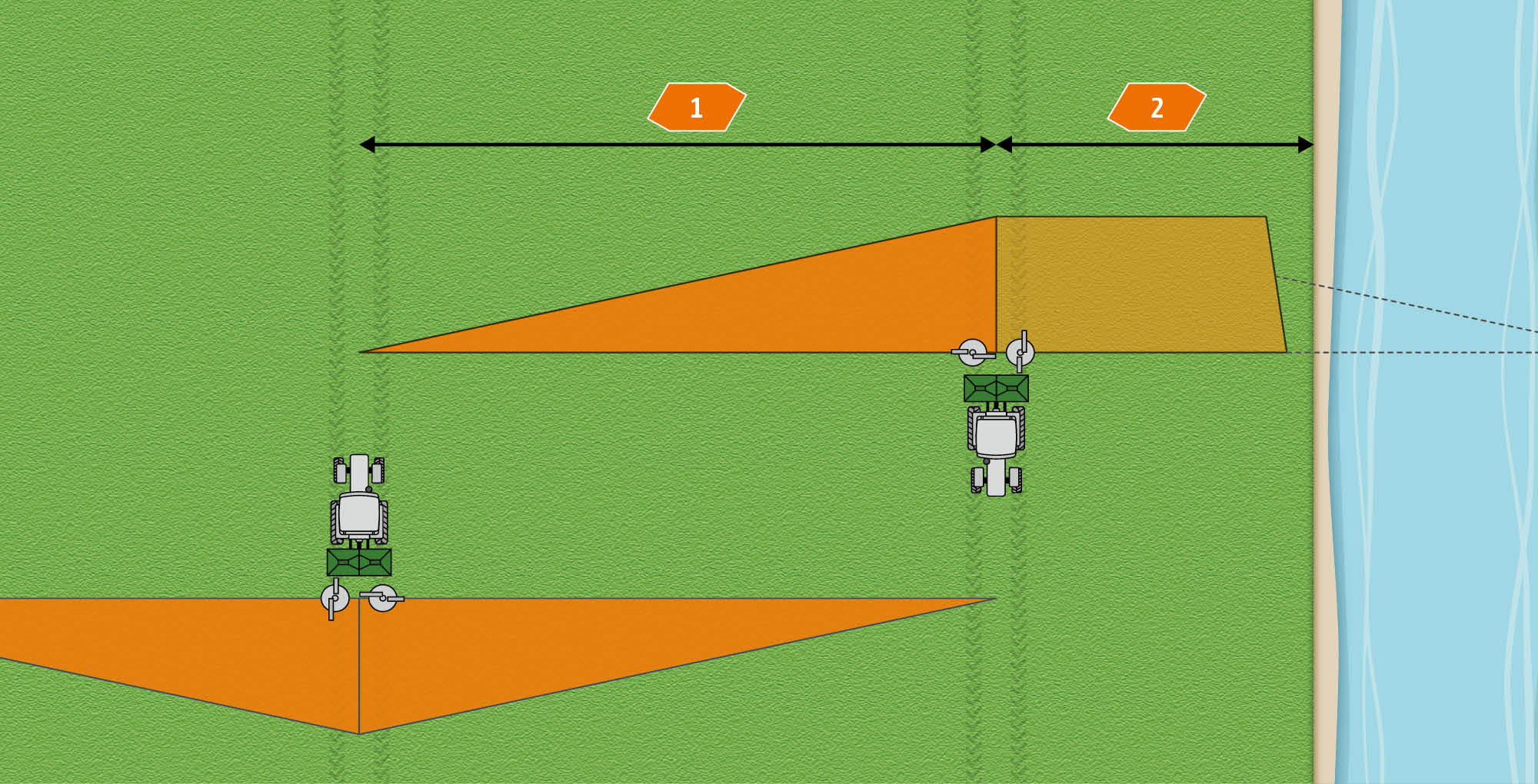

Water course spreading (environmentally oriented setting)

If there is a body of water directly at the edge of the field, a defined distance to the water must be maintained when fertilising according to the fertiliser regulations. For this purpose, the throwing distance is further reduced in combination with the shutter slide.

The AutoTS border spreading system makes it possible for the operator to reliably generate a very steep cut-off to the border spread pattern and thus create the perfect growing conditions right up against the field edge. Compared to other border spreading systems, a significant increase in yield is possible.

Automatic rate reduction when border spreading is possible with the AutoTS spreading system. Rate changes are possible in freely selectable percentage steps. As the two spreading discs can be operated independently from one another, the change can be applied to just one, or both sides.

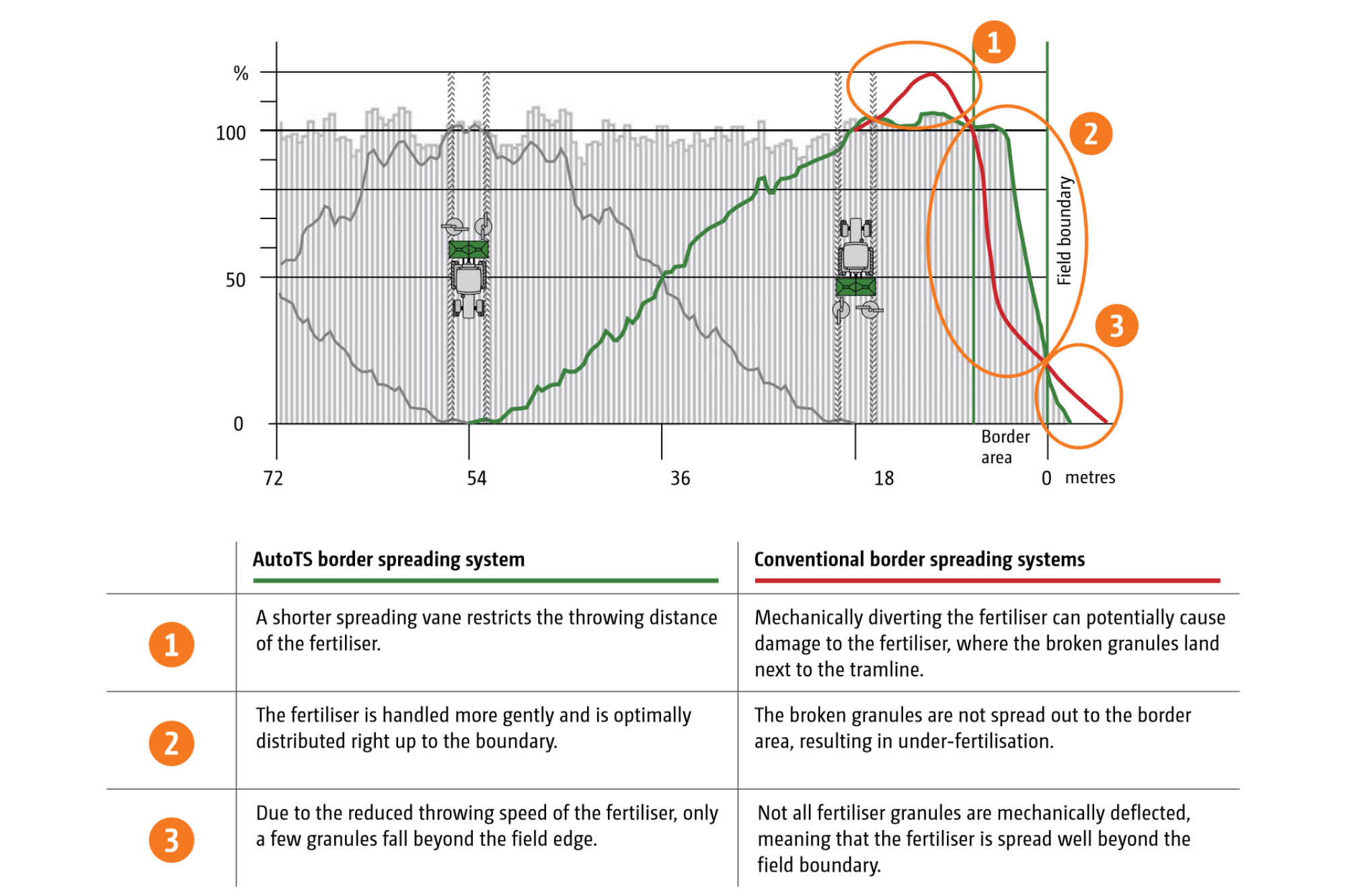

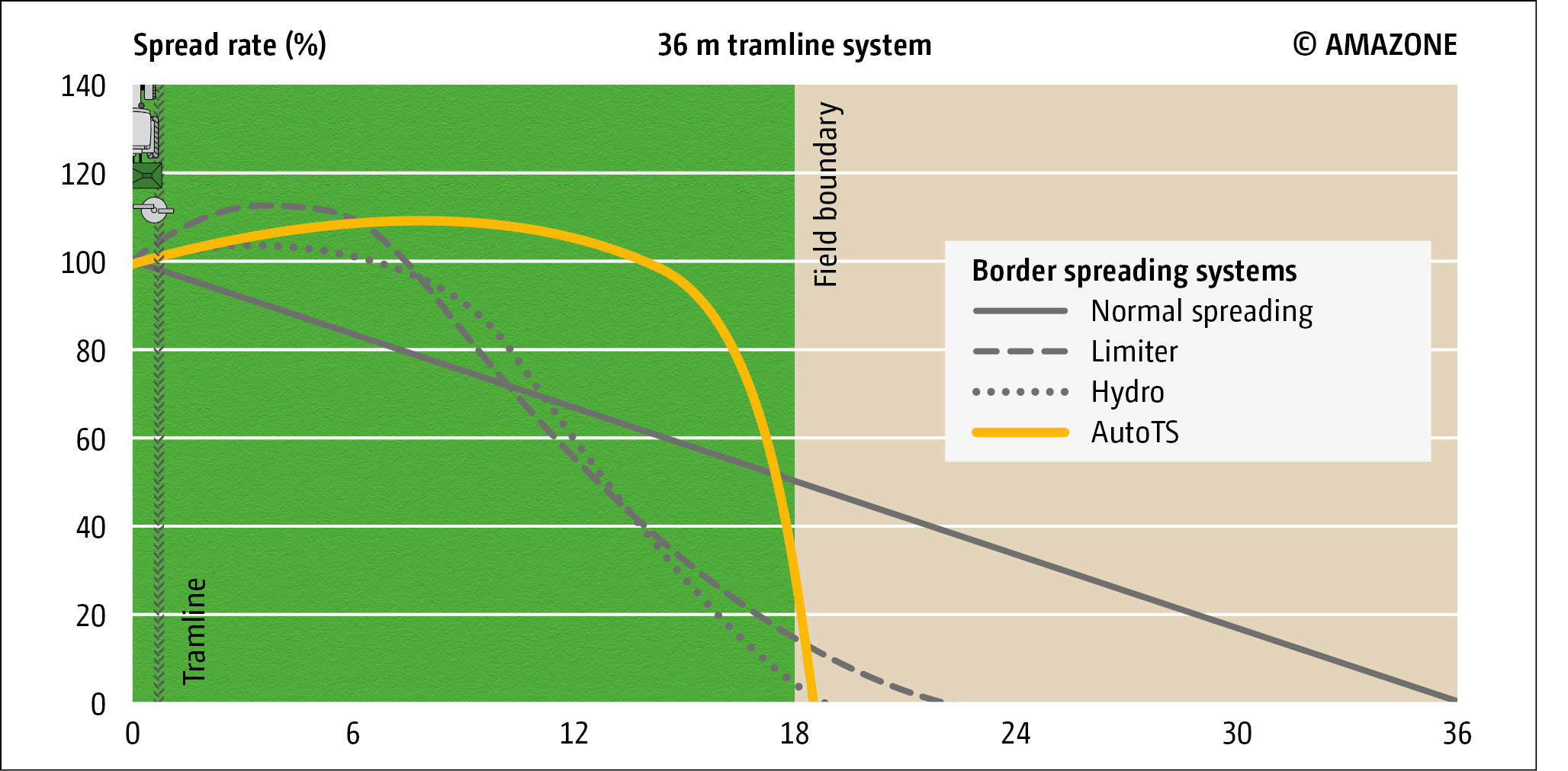

Field trials prove the best border spreading results

The aim of the field trial was to demonstrate the fact that border spreading systems provide not only ecological benefits, but also that they have a great influence on the potential yield in the field boundary area.

Precise technology is required to spread the full rate of fertiliser right up to the field boundary, even at the larger working widths, as well as avoiding any fertiliser losses outside the field boundary.

AutoTS meets these requirements. This means that higher yields can be achieved, even at the field boundary.

Core messages of the trial

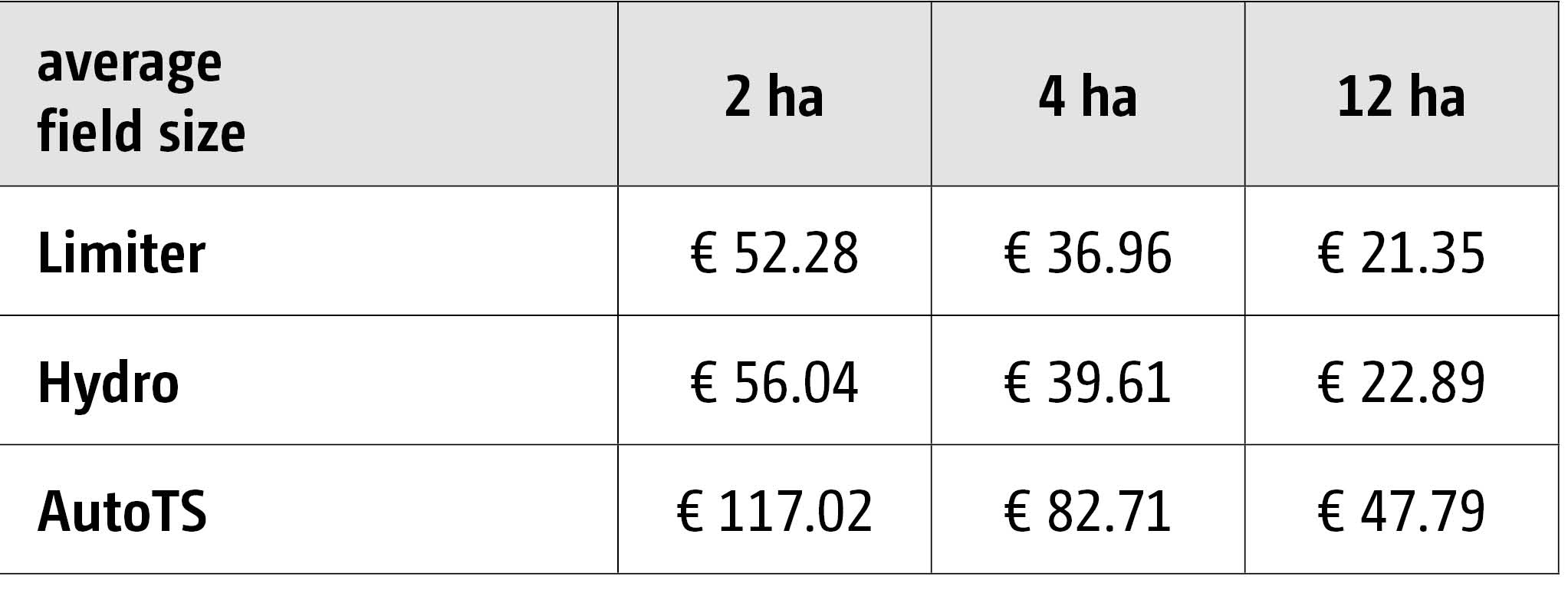

- A wider working width or smaller field sizes increases the level of return on a boundary spreading system.

- The AutoTS spread patterns show a relatively even spread rate all the way up to the boundary where the rate then drops steeply.

- Any underdosage was clearly reduced by using AutoTS, which translates into higher yields.