Accurate fertilisation in focus

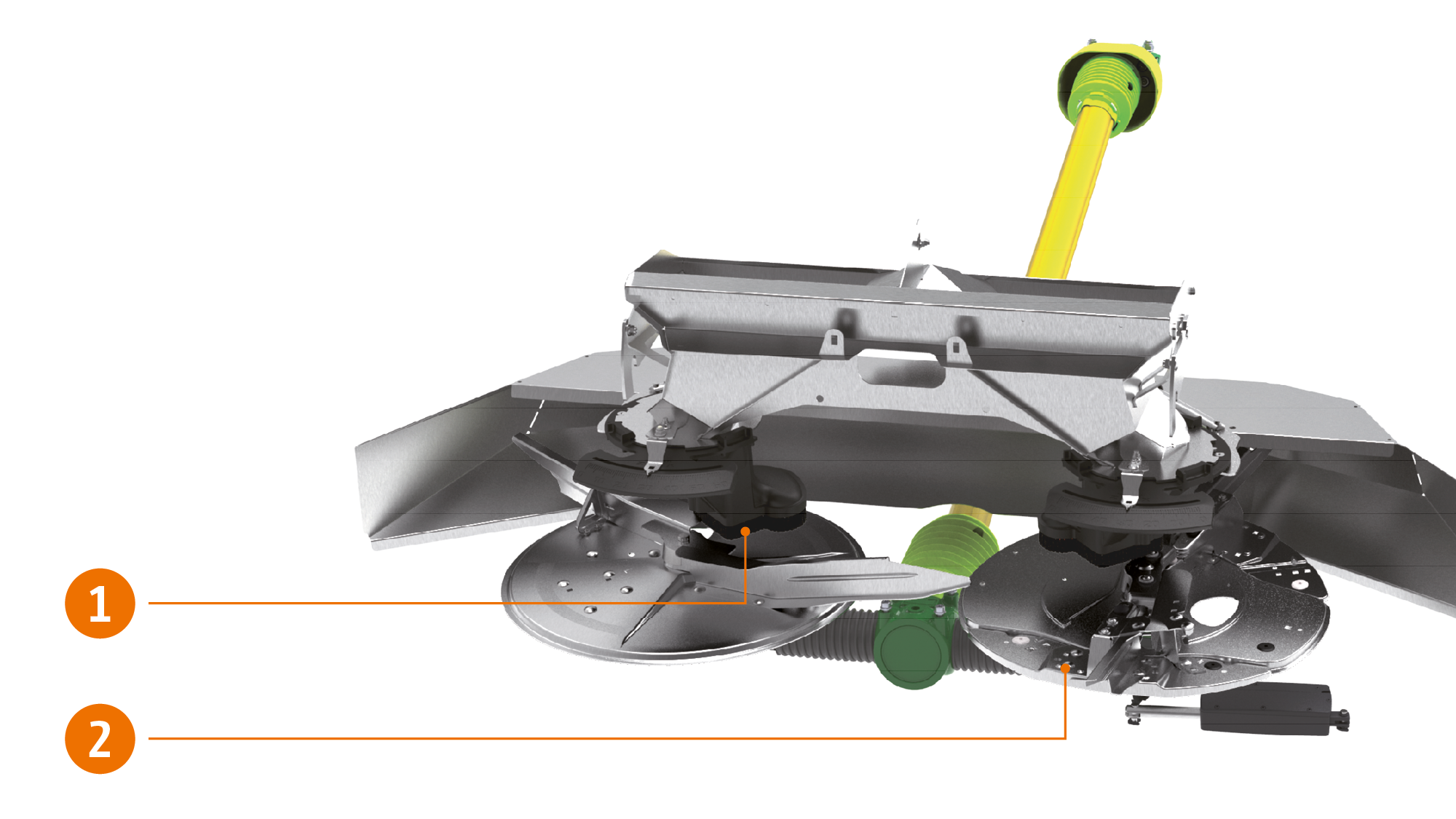

Tronic – mechanical spreading disc drive

The spreading unit of the ZG-TX is mechanically driven. In this case, the spreader is protected from overload, as standard, by a universal drive shaft with friction coupling. The input speed from the tractor PTO is transmitted via the central gearbox resulting in an increased spreading disc speed. This allows spreading at low engine revs across the maximum working width.

- Between 1 and 16 part-width sections are switchable, depending on the equipment level chosen.

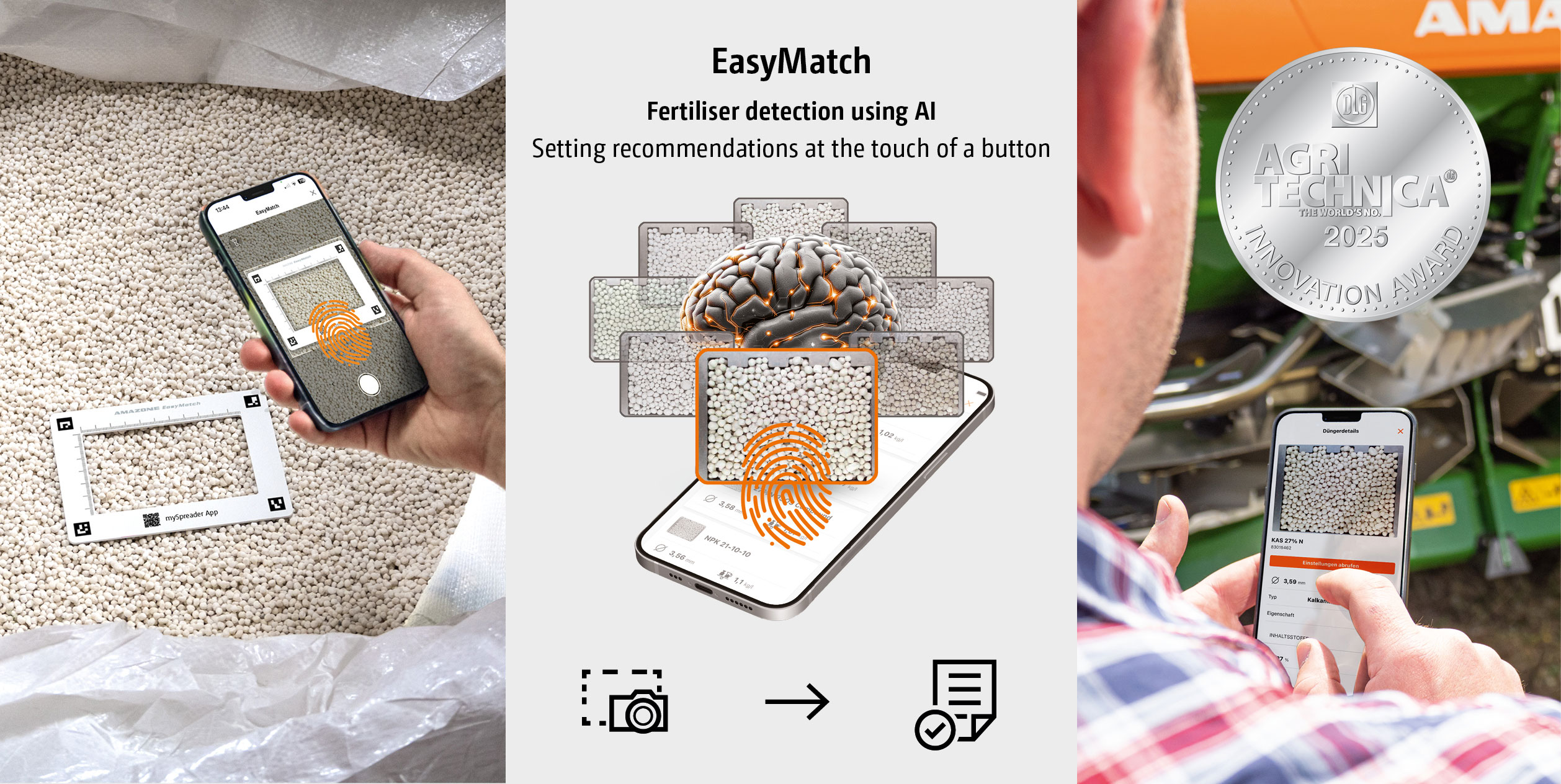

The term combi spreader has so far been used to describe machines which meter either mineral fertilisers or lime onto two spreading discs via a floor belt. However, the demand for optimum precision is also increasing in the customer sector for combi spreaders. Against this background, AMAZONE decided to break new ground in the field of fertiliser application and combine it with the proven precision of the TS spreading system. The result is new in many respects!

Instead of a simple chute via which the fertiliser is guided onto the disc, a defined delivery point adjustment is integrated in the ZG-TX. This in turn enables features such as HeadlandControl and Section Control in the optional electric version.

The swivelling of the delivery system offers a wide bandwidth of possible working widths. The working width range of 15 m to 54 m is covered by just 3 sets of spreading vanes.

The benefits

- Perfect lateral distribution with working widths of up to 54 m

- Precise setting

- SectionControl with 16 part-width sections

1. Defined delivery point adjustment

2. Spreading disc with disc-integrated AutoTS on the right-hand side