The spreading disc drive – Mechanical or hydraulic, choose for yourself!

Tronic – mechanical drive

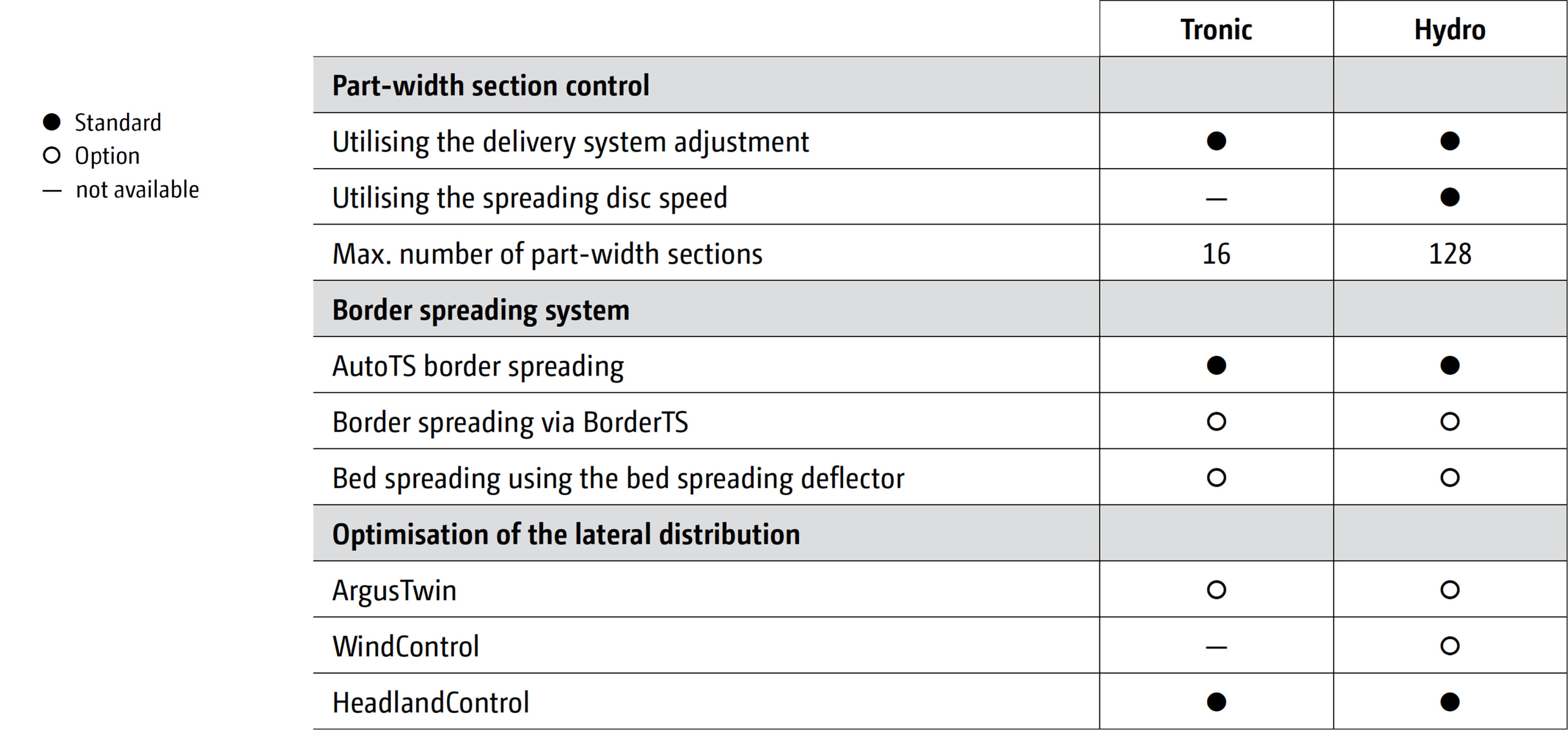

The spreading unit is driven via the PTO shaft on the Tronic version. In this case, the spreader is protected from overload, as standard, by a universal drive shaft with friction coupling. The input speed from the tractor PTO is transmitted via the central gearbox resulting in an increased spreading disc speed. This allows fertilisation at low engine revs right through to the maximum working width.

The benefits

- Section Control with 16 part-width sections is possible in combination with the electric delivery system

- Robust drive with a fuel-efficient gear ratio of 1:1.33

- Standard PTO shaft with a friction clutch provides protection against overload

Hydro – hydraulic spreading disc drive

The Hydro version makes use possible irrespective of the tractor’s engine revs, even with different spreading disc speeds. In this way, fuel consumption is reduced and a particularly comfortable and precise spreading is ensured. The spreader also operates at various different spreading disc speeds when border spreading, so that the best-possible lateral distribution can be achieved in the overlap area and to the field boundary.

The benefits

- The side-independent regulation of the spreading disc speed permits even more precise spreading on wedge-shaped fields. Up to 128 part-width sections are possible in combination with Section Control.

- In combination with WindControl, side-independent regulation enables windy conditions to be compensated for

- Pressure filter as standard