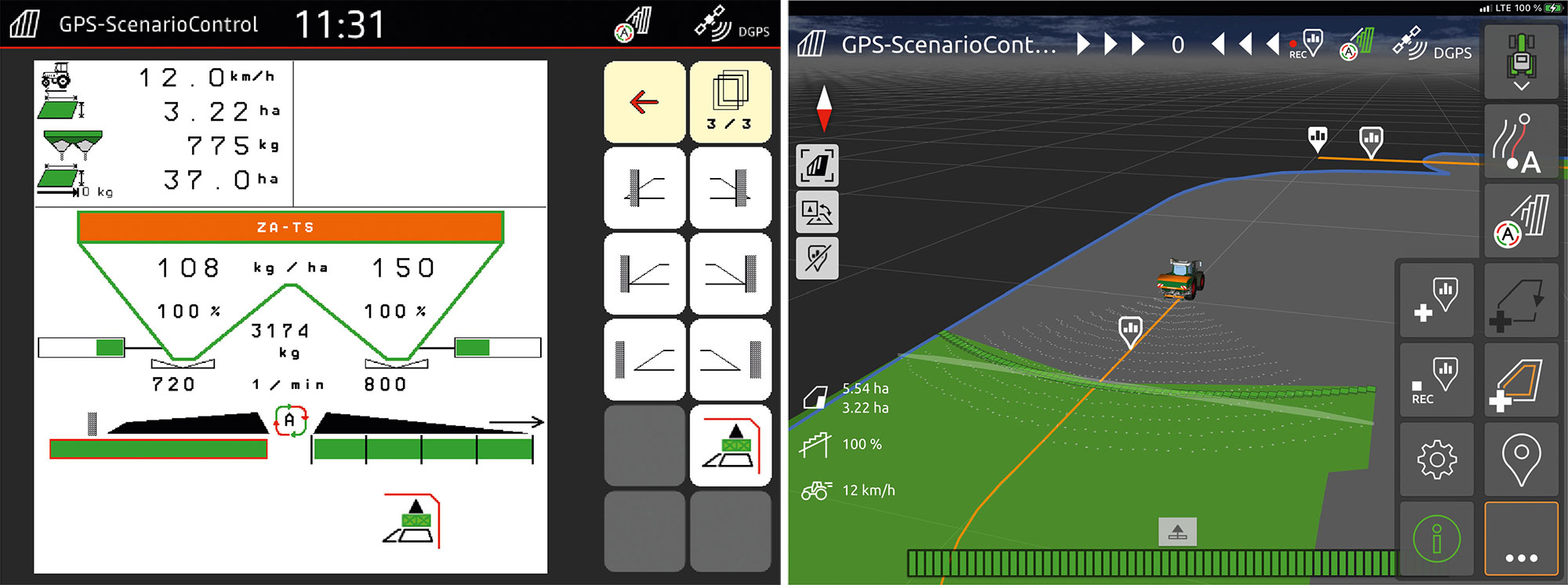

GPS ScenarioControl

Terminal software for the automation of complex switching processes

The precise application of mineral fertilisers just where they are required plays a critical role in saving costs and utilising resources. In this context, various border spreading procedures are used to provide legally compliant fertilisation. The GPS ScenarioControl system is used to automate certain functions of the AMAZONE fertiliser spreader based on a previously plotted scenario, preventing operator errors during subsequent applications.

The problem: changing drivers can lead to operator error

When applying fertiliser, drivers have to juggle various tasks. Firstly, they need to ensure optimal lateral distribution of the material to be spread, as well as maintaining the desired application rate of the fertiliser. Secondly, they must ensure that the most appropriate border spreading procedure is used alongside ditches, footpaths or field boundaries, to guarantee legally compliant and precise fertilisation. This can lead to operator errors, especially when changing drivers, as the right border spreading procedure is not activated or deactivated in the right place. Lack of driver knowledge can also lead to non-compliance when applying fertilisers. In addition, there may be frequent questions about the correct application between the employee and the manager, taking up valuable working time.

Record and store the right driving strategy

When crossing the field for the first time with the fertiliser spreader, all the switching points, driving route and driving direction can be automatically plotted by an experienced driver using GPS ScenarioControl by pushing the record button. The switching points are clearly marked on the map and the driving direction is visualised with arrows. The fertiliser spreader offers border, water-course and side spreading, as well as one-sided spreading inside the field boundary on headlands (HeadlandControl). GPS ScenarioControl is integrated in the AmaTron 4 ISOBUS operator terminal and can be viewed and operated via the AmaTron Twin display extension.

Automation of complex switching processes and reduction of driver workload

In the following application, the driver only needs to activate the previously plotted scenario and the fertiliser spreader will automatically perform the saved switching processes. GPS ScenarioControl enables the precise, resource-efficient use of fertiliser, as the various spreading procedures are performed in exactly the right places. This ensures that any subsequent applications by other drivers are legally compliant. In addition, drivers can use the pre-plotted, optimised field route as a guide. This reduces unnecessary empty trips and flattening of crops by taking a wrong turn in the tramlines. GPS ScenarioControl reduces driver workload by eliminating the need to juggle different actions and control tasks, and enables the use of multiple drivers during the fertilising season. There is no need for questions about the correct interpretation of the spreading procedure between the driver and manager, enabling an optimal workflow. As a result, GPS ScenarioControl can also deliver huge time savings, convenience and safety for contractors,

In future, GPS ScenarioControl will also be compatible with other AMAZONE ISOBUS machines. This route function is already available for crop protection sprayers from AMAZONE, where it considerably reduces the workload as well.

The advantages at a glance:

- Always the same switching processes on every pass in the field

- Reduced workload by following a previously plotted scenario

- Prevention of operator errors

- Optimised, resource-efficient fertiliser usage

- Legally compliant fertiliser application guaranteed

- Correct application in poor visibility, e.g. darkness or fog

- Always the same driving pattern across the field

- Assists drivers who are unfamiliar with the area

- Supports inexperienced drivers

- Less strain on the driver

- No flattening of crops by taking wrong turns in tramlines