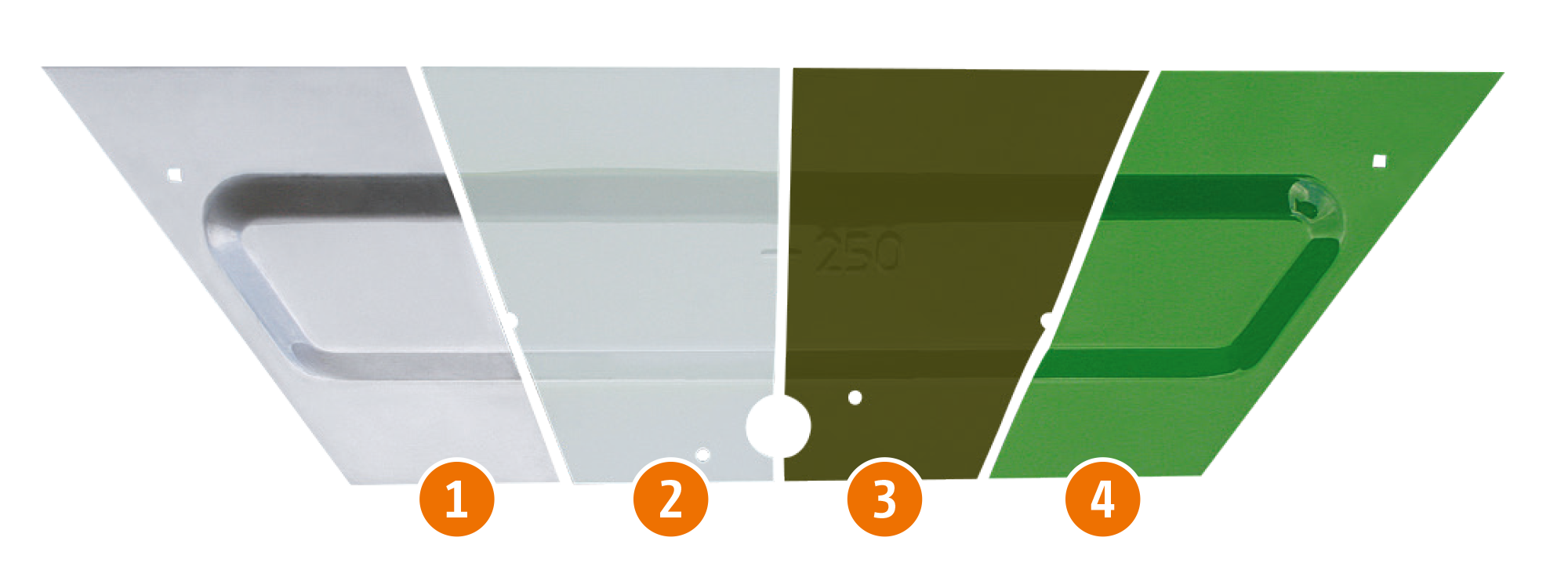

The best of both worlds - KTL cathodic dip-paint coating combined with powder coating

High-quality, multi-layer paint finish

The paintwork on a fertiliser spreader is exposed to particular demands. The paintwork is intended to protect the spreader from corrosion, especially when handling fertiliser and where moisture is involved. Starting with the 2022 model year, there is a new painting process for the ZA-V, ZA-TS and ZG-TS fertiliser spreader ranges. This involves, on the one hand, a cathodic dip painting process (known as KTL) for priming to give the best possible protection on the internal surfaces of tubes and box sections and, on the other hand, a powder coating process to create a high-quality visual finish with extra-thick paint providing increased protection against mechanical demands.

7 year manufacturer’s guarantee

Based on this optimum painting process, AMAZONE is able to offer its customers a manufacturer guarantee of seven years against rusting through, starting with the 2022 model year. From 01/01/2023, customers can apply to have the guarantee activated for ZA-V, ZA-TS, and ZG-TS models, starting from the 2022 model year. This registration is done very simply via the

manufacturer’s portal, myAmazone, bearing in mind the terms and conditions (www.amazone.net/7-years) stated there. After registration, one can continue to work without any worries.The benefits

- Cathodic dip painting process

- Suppression of rust infiltration

- Best possible protection, even on the inner surfaces of tubes and box sections

- Powder coated top coat

- Double protection through additionally applied powder coating

- Improved resistance against everyday wear and tear

- Quality and reliability

- All the components on the spreading system and all hydraulic fittings are made from stainless steel

- Impact, UV and chemical resistant plastic sieves

High-quality multi-layer paint finish – the most modern from all angles:

- 14-step paint preparation (e.g. degreasing)

- Zinc phosphating provides the most effective counteraction of rust formation

- Thick cathodic dip priming for full corrosion protection, even in cavities and those hard-to-reach areas

- Powder coating for a high-quality appearance and extra thick paint for increased protection against mechanical demands