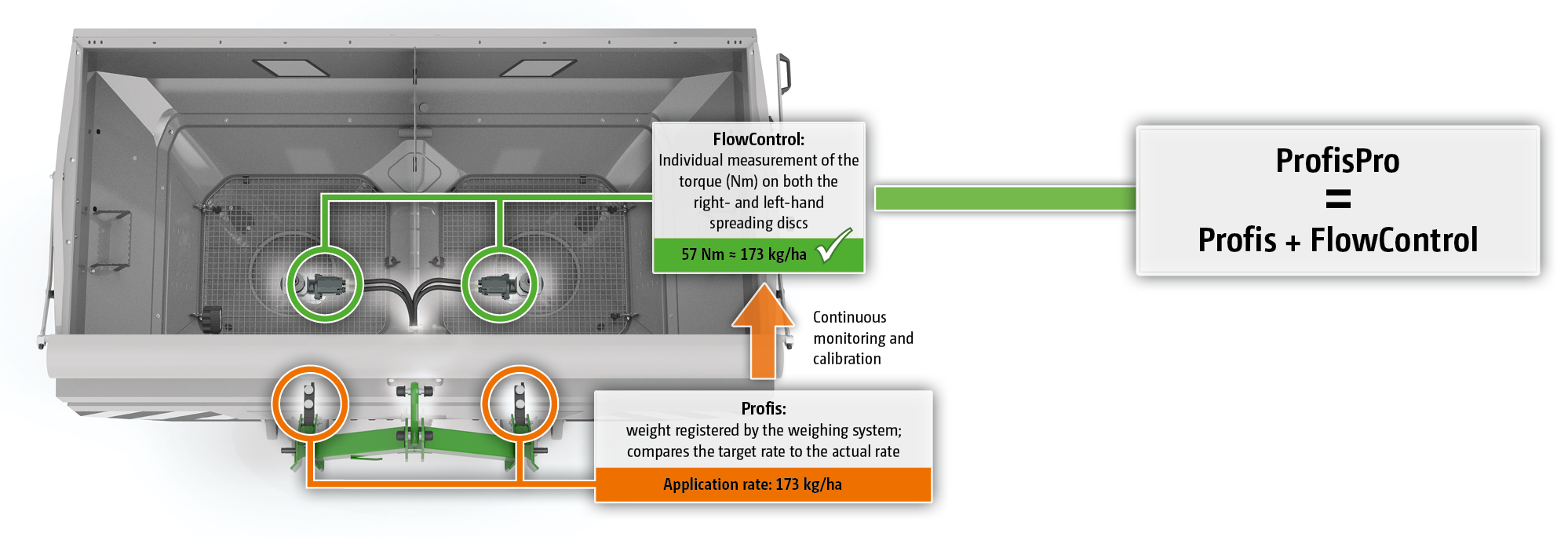

ProfisPro weighing system with torque measuring

Profis – Intelligent weighing system

With the frame-integrated Profis weighing system, the hopper and its frame are connected to a separate chassis via two 200 Hz weigh cells on the ZA-TS or via four weigh cells with the ZG-TS. Thus, there are no weight measuring points which are influenced by the traction forces of the tractor. Precise online weighing every 25 kg is the result! An additional tilt sensor is fitted to compensate for the inclination of the machine on slopes. In the case of the ZG-TS, the signal is also used to counter-steer on slopes via the steering axle to prevent the ZG-TS from drifting downhill.

FlowControl – torque measuring system

The FlowControl torque measuring system reliably monitors the torque on each spreading disc drive from the very first second and can adjust the position of each spread rate shutter in the event of a deviation from the target rate irrespective of the side. The applied rate is precisely documented for a field-related nutrient balance. In addition, the application rate can be altered at any time by pressing a button on the ISOBUS terminal.

The benefits

- Absolute precision from the very first second

- Side-independent calibration of the application rate in any field situation

- Highest precision through simultaneous monitoring of the weighing system and the torque measurement

- Detection of running empty and any blockages

- Accurate weight recognition with indication of the quantity remaining and the remaining area

- Documentation of the total amount applied

- Additional features for ZG-TS: control of the steering axle on hilly terrain and load-dependent braking force control