HeadlandControl – optimum lateral distribution on the headland

The problem: Over- and under-fertilisation on the headland

Fertiliser spreaders have a high throwing distance behind the machine. In practice, the switch-off points are usually only achieved when the tractor is turning on the headland. The arc of spread behind the tractor and round to the side creates areas that are either over- or under-fertilised.

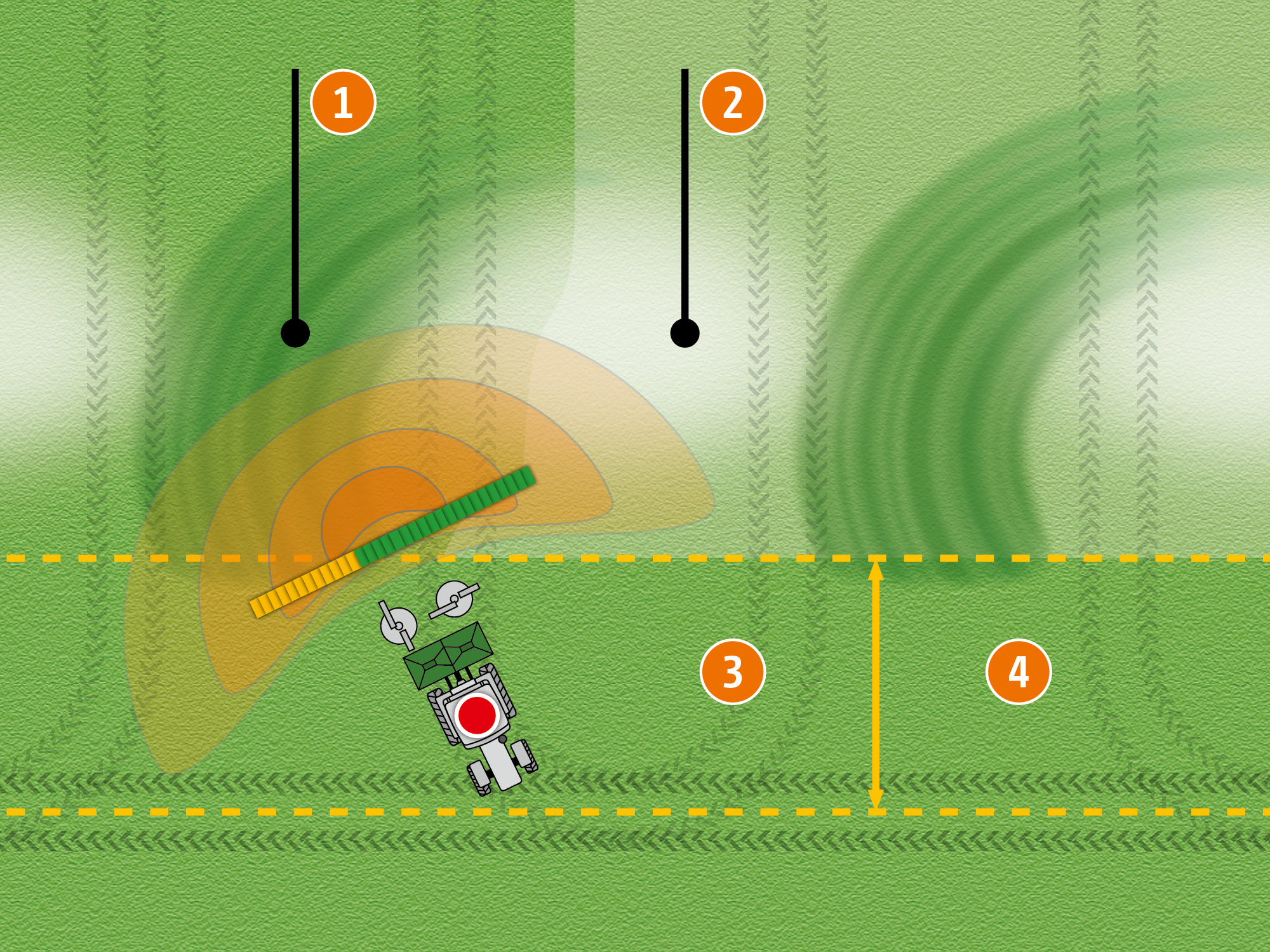

Switch-off time on the headland: Without HeadlandControl

- Spreader switches off too late and is already turning

- Tractor would have to drive beyond the headland tramline

Result: Over- and under-fertilised zones are created

- Over-fertilisation (dark-green)

- Under-fertilisation (white)

- Standard headland

- Inner throwing distance without HeadlandControl

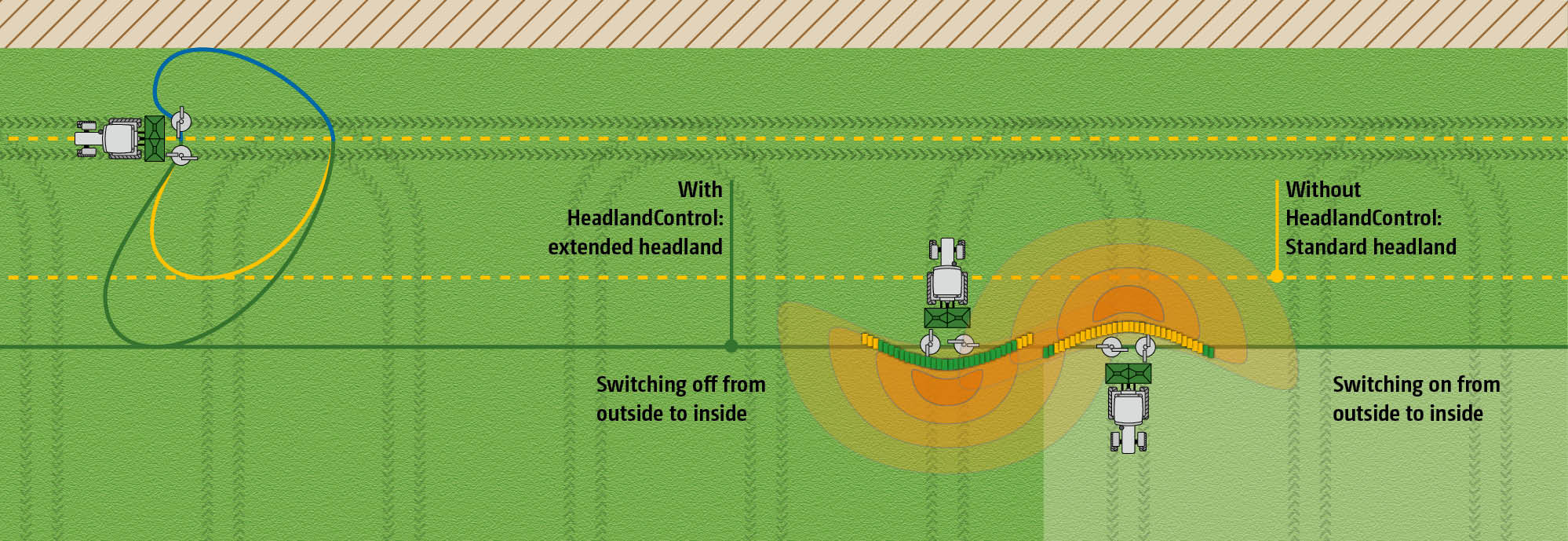

The solution: HeadlandControl

When HeadlandControl is activated, the throwing width and spread rate are increased on the field side, so that the switch-off point is moved towards the inside of the field. Furthermore, the new part-width section control, which is now adapted to the shape of the spread fan, causes the part-width sections to be switched off from the outside to the inside when entering the headland. Over- and under-fertilised zones on the headland are subsequently avoided.

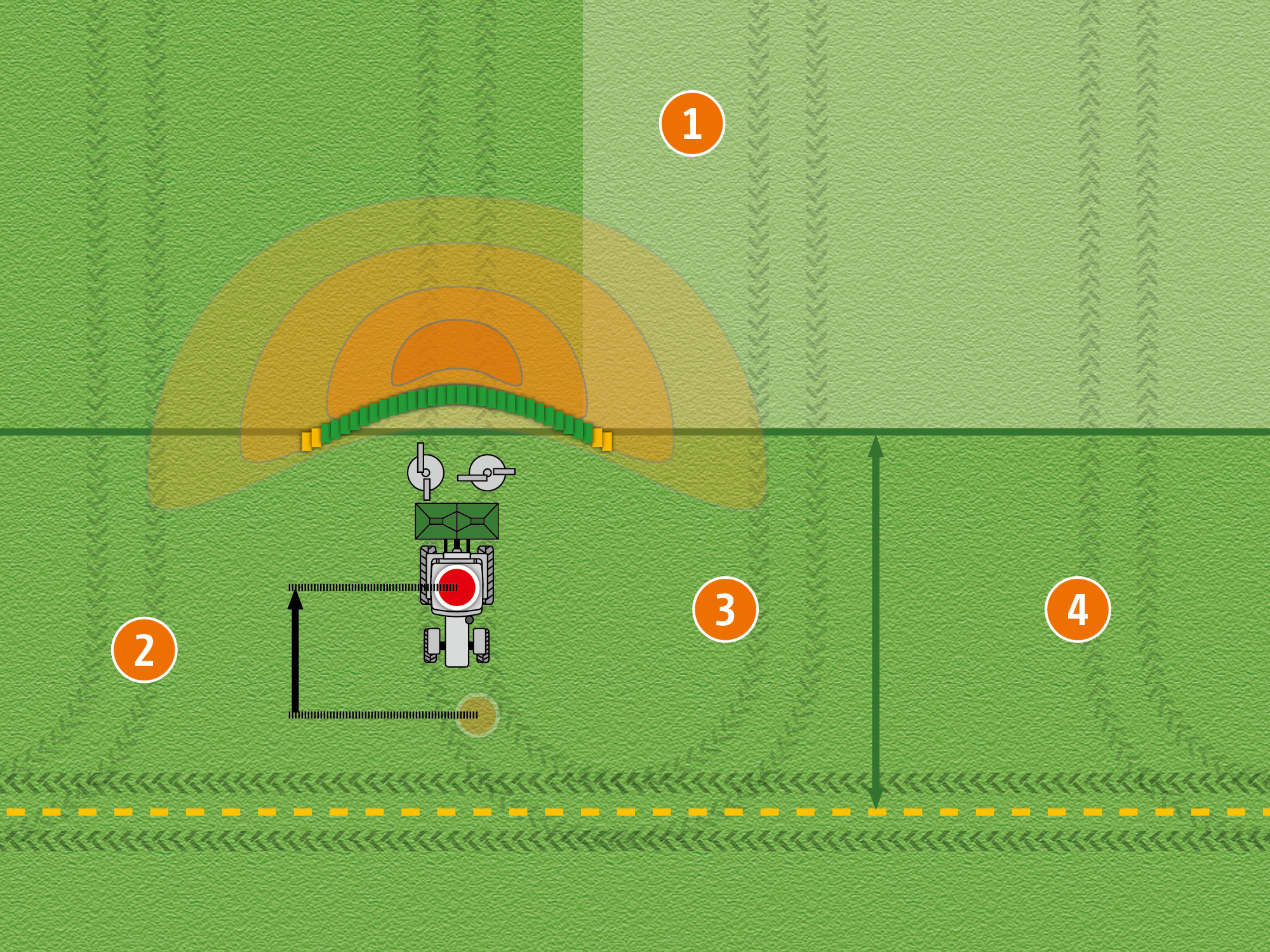

With HeadlandControl

- HeadlandControl means that the spreader continues to apply fertiliser to the crop when it is on the headland

- The tractor can follow the wheel tracks of the sprayer

Result: Uniform crops across the headland

- Improved lateral distribution at the headland

- Switch-off point moved

- Extended headland

- Inner throwing distance with HeadlandControl