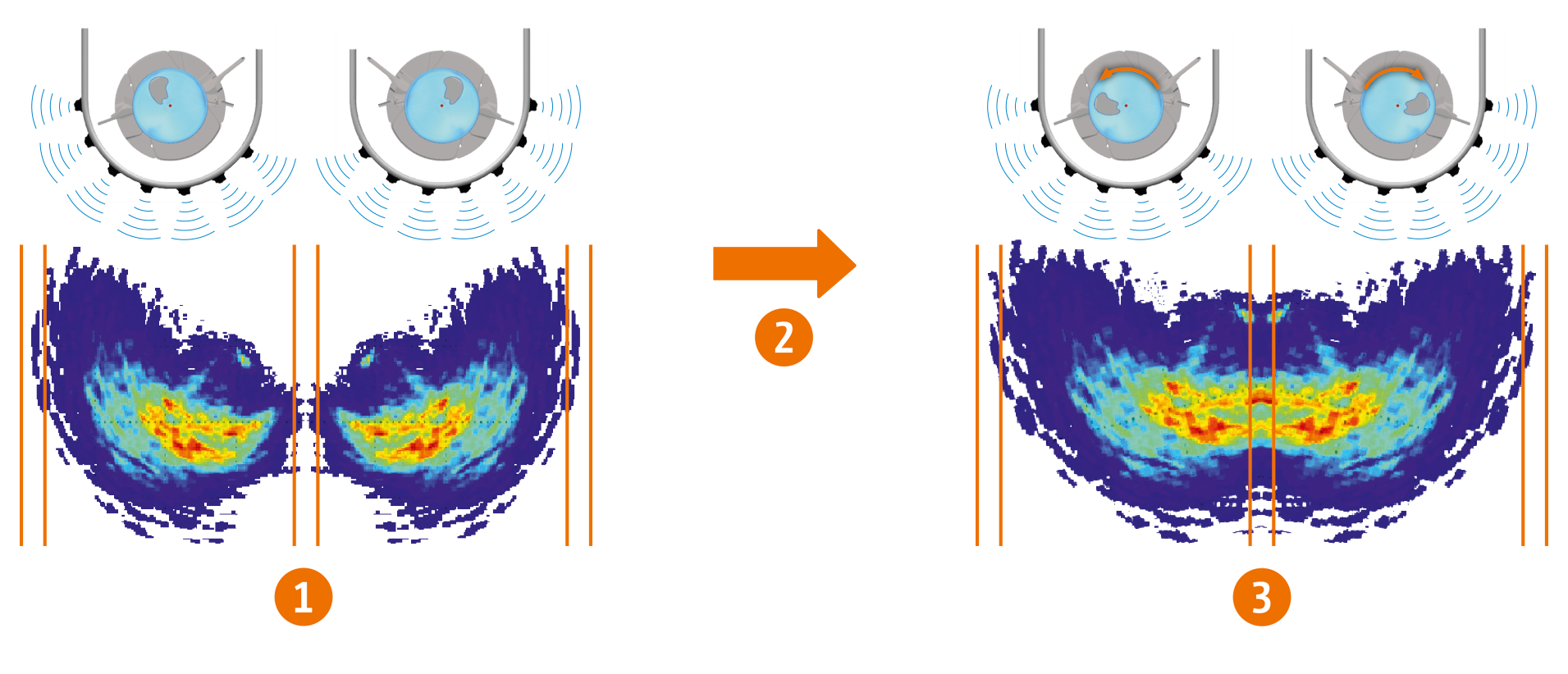

ArgusTwin – Automatic adjustment to the optimum lateral distribution

The ArgusTwin system always ensures optimum lateral distribution of the fertiliser via permanent online monitoring and correction of the delivery system. This leads to a more effective fertiliser use and forms the basis for optimum crop management.

The spread fan acquisition in the Argus system is based on measuring the lateral distribution by means of radar technology which is insensitive to dust and dirt and delivers reliable results under practical conditions. ArgusTwin monitors both the left- and right-hand spread fan and corrects the electric delivery system if necessary.

Automatic delivery system adjustment

Via the ISOBUS terminal, the application rate, and any further relevant data relating to the fertiliser to be spread, are entered from the setting chart. For the Argus system, the spreading chart has been updated to include the throwing angle that gives the optimum lateral distribution. Utilising this value, ArgusTwin constantly checks whether the predetermined direction of throw for that fertiliser is in fact being maintained by the spreading discs. When the actual throwing width deviates from the “desired” throwing width due to inconsistencies within the fertiliser, worn spreading vanes, working across slopes or during starting and stopping procedures, the spreader readjusts, on its own, the setting for the delivery system – and that of each side individually. The only pre-condition for its use is the electric delivery system adjustment.

The benefits

- Constant on-line monitoring of both spread fans

- Maintains an optimum lateral distribution of the fertiliser even with:

- variable fertiliser quality

- environmental influences, such as moisture and dew

- fertiliser coating on the spreading discs

- Automatic slope compensation of the spread pattern

- Positioned protected directly above the spreading discs

- The problems in practice – poor lateral distribution, for instance, due to a change in fertiliser properties

- Automatic adjustment of the delivery system via ArgusTwin

- Perfect lateral distribution enables uniform crops, even with varying fertiliser quality and properties