Slope spreading kit for the ZA-V

Precise fertiliser distribution on slopes

Uniform crops, even on slopes

Exact fertiliser distribution over the entire working width is the basis for uniform and resource-efficient crop management as well as exploiting the full yield potential. This does not present any difficulty for modern-day technology in flat areas. The topography has a significant impact on the spread fan and therefore on the fertiliser distribution in the field in extremely hilly terrain. To counteract this effect, AMAZONE offers a simple yet efficient slope spreading kit for the ZA-V fertiliser spreaders.

Simple special option with a high impact

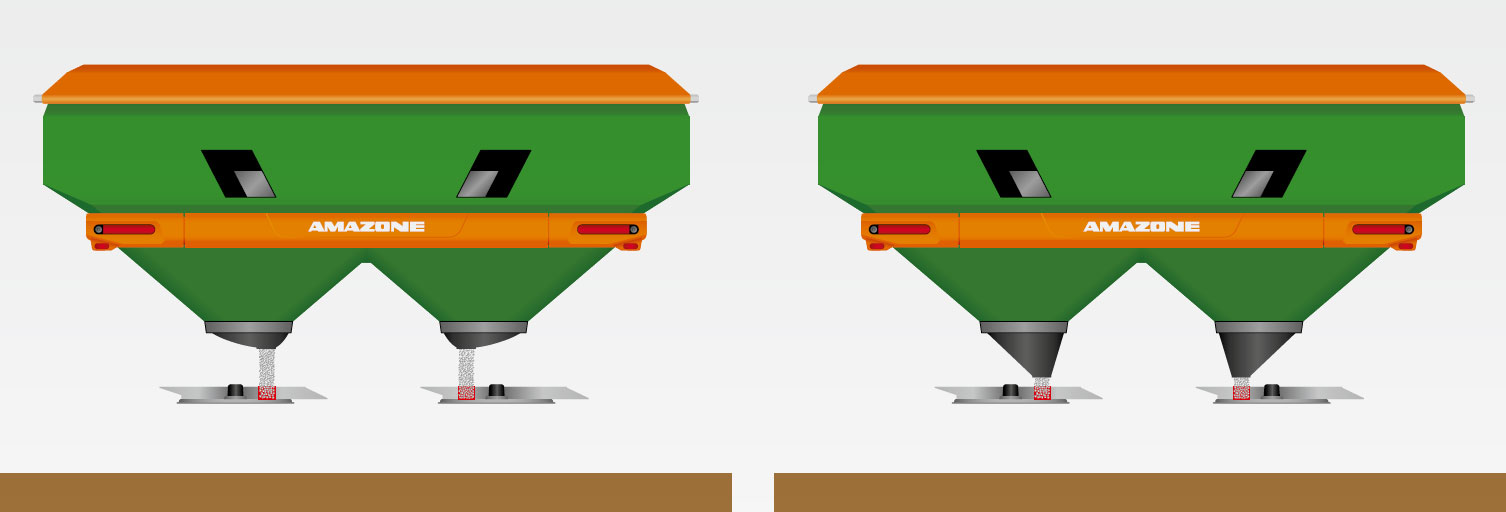

The fertiliser granule path is precisely defined in flat areas. After the shutter has opened, the material falls onto a defined point of the spreading disc under gravity. The granules are accelerated by the spreading vanes and distributed over the field.

There are various spreading scenarios for spreading on slopes. Spread patterns in both uphill and downhill spreading are different from those on flat areas. The same applies to spreading at right angles to the slope. The material delivery points on the disc in these practical situations are changed by the inclination of the fertiliser spreader. Whereas the fertiliser strikes the spreading disc at right angles in flat areas, it is shifted in extremely hilly terrain, which in turn has a direct effect on the spread pattern. The fertiliser is guided down onto the disc over a longer distance by means of the slope spreading kit (Graphic 2), thereby minimising the impact of the slope to a considerable extent.

The kit is not only available for new machines but can also be retrofitted to existing ZA-V spreaders.

Quantifiable economic and ecological benefits

This simple special option can optimise the lateral distribution of the fertiliser on slopes. In particular, the throwing distance and the lateral distribution of the fertiliser are improved by the slope spreading kit. As a large-scale field trial at InnovationsFarm in Austria showed, the lateral distribution on extreme slopes can be optimised by a coefficient of variation of at least 5 % as a result of the slope spreading kit. This was verified both in application at right angles to the slope as well as when fertilising uphill and downhill. Apart from the economic aspects, this also has important ecological benefits for the environment.