ContourControl boom guidance for UF 02 mounted sprayers

Maximum precision and output for mounted sprayers

As an alternative to DistanceControl automatic boom guidance, AMAZONE now also offers the automatic,active ContourControl boom guidance for the UF 1602 and 2002 on boom working widths from 27 m.

The active ContourControl boom guidance guarantees precise application at high driving speeds for maximum work rates and yet exact, close distances to the target surface and so low drift. This is an important component in precise, efficient and environmentally-friendly crop protection, even on smaller and medium-sized farms.

ContourControl

The AMAZONE ContourControl active boom guidance is a ground-breaking fully automatic boom guidance system that is also utilisable on three-point linkage mounted sprayers. The boom tilt is controlled by a pre-pressurised hydraulic cylinder on both sides. Rapidly-switching hydraulic valves bring the boom to the desired position. This actively eliminates any of the various effects caused by uneven ground and other influences while driving. The cylinders for positive and negative angling of the two outer ends of the boom are controlled using the same principle. This allows the boom to follow highly uneven topography to maintain an optimal distance to the target surface across the entire working width, even on extremely hilly terrain – and at unprecedented speeds.

Less than 50 cm distance to the target surface with 25 cm nozzle spacing

Distances of less than 50 cm to the target surface can also be precisely maintained using the AmaSwitch quad nozzle body and 25 cm nozzle spacing.

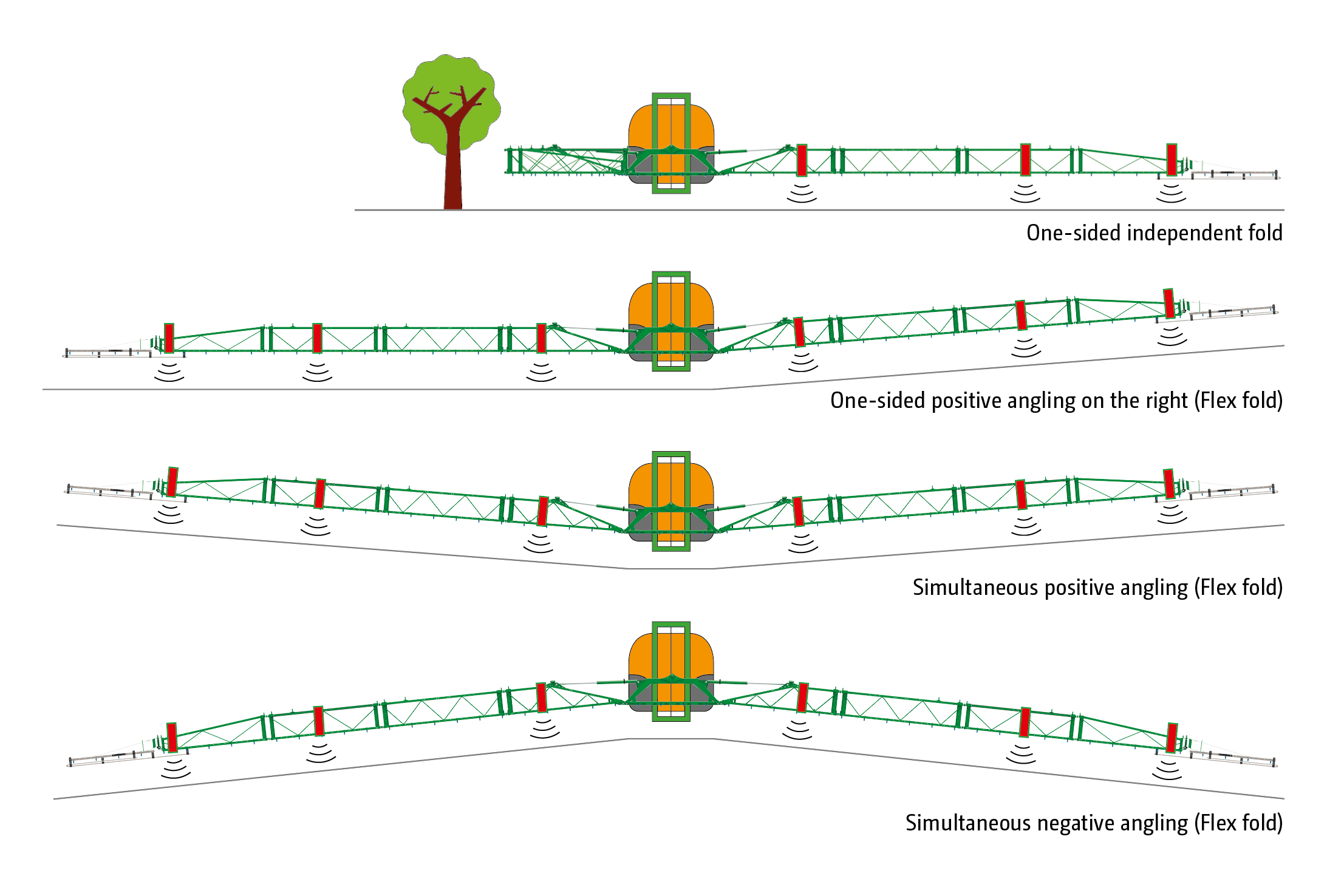

Flex-fold

The standard, electro-hydraulic Flex-fold mechanism of the boom with ContourControl can control each pivot point on the boom separately. This allows the boom to be folded out to a reduced working width from the tractor cab. The overload protection within the hydraulic system is simultaneously used as break back protection when working at reduced working widths. The individual control of the hydraulic cylinders at the pivot points allows up to two segments to be folded out at a time on each side of the boom. This considerably reduces down times when folding the boom in and out.

Future-proof technology

New and innovative technologies, such as band application on row crops, or spot application on weeds, are now made possible for mounted sprayers.

Precise application with maximum work rates in a compact format for sustainable and environmentally-friendly agriculture

ContourControl boom guidance guarantees close distances to the target surface across the entire working width, without compromising the driving speed and work rates of the sprayer, a key feature in crop management. Farmers demand an effective, sustainable use of machinery at the right time. The active ContourControl boom guidance now delivers the required output in the compact, manoeuvrable, mounted sprayer segment, without compromising on boom guidance and application quality in small and medium field sizes. Exact distances to the target surface along the entire boom width helps to reduce drift and protects the environment. The precise maintenance of the boom height ensures optimal lateral distribution across the entire working width and high application quality.

The advantages at a glance:

- Fast and precise boom guidance for maximum work rates

- Distance of less than 50 cm to the target surface in conjunction with AmaSwitch fitted with quad nozzle bodies and 25 cm nozzle spacing for reduced drift

- Flex-fold for rapid folding procedures

- Simple changeover of boom width to reduced working widths with integrated break back protection for use in different tramline systems

- Future-proof technology, optimally equipped for band and spot application

ContourControl boom guidance for UF 02 mounted sprayers