Sep 12, 2023

AMAZONE AutoTill

The solution for automated and autonomous soil tillage

Automatic setting and function monitoring of the machine is made possible thanks to the new AutoTill system for mulch cultivators. This system makes it possible for the machine to set itself automatically in accordance with pre-defined parameters (working depth and speed) and to monitor the functionality of the machine independently.

AutoTill can, in the first step, also monitor the functionality of the machine, in combination with a standard tractor, using ISOBUS, and can warn the driver of problems with the machine.

In the second step, the system can communicate via ISOBUS, in combination with a standard tractor and an AgXeed Box, and can independently react to the problems from the error messages received from the sensors in the machine. This means that the driver’s tasks are reduced even more, giving him more time to concentrate on his surroundings.

In the third step, AutoTill operates autonomously with a robot. The cultivator can communicate with the robot in this level, thanks to ISOBUS communication, and can monitor the functionality of the machine and react independently to irregularities in the job. The mulch cultivator informs the robot how to resolve any potential problems. This ensures high levels of operational reliability in autonomous working.

AutoTill demonstrates its strengths in the second level on long working days at high working speeds. It is often difficult to monitor the whole machine from the cab on account of the dust being generated, particularly with wide working widths. This increases the pressure on the driver.

AutoTill provides support for the driver and thus reduces his workload. This means that even long working days are no problem for the driver, and the quality of work remains at a consistently high level.

A great benefit of the third step is that the machine is set up ready for autonomous driving as a result of the sensor systems. This will increase in significance in the future on account of the skill shortage in agriculture.

AMAZONE has concentrated on looking at different sensor systems for monitoring the performance into the mulch cultivator in order to ensure the successful introduction of autonomous soil tillage.

Various different sensor systems for monitoring the job have been integrated into the machine to make AutoTill feasible.

Automatic setting of the working depth in the second and third steps

One difficulty in day-to-day working with a mulch cultivator, is aligning the machine parallel to the ground as the working depth changes. Consistent, even working can only be guaranteed by parallel alignment of the frame to the ground using the top link.

The working depth can be set automatically to suit the surface thanks to the tilt sensor on the frame and the distance measuring system on the depth control cylinder of the roller. Using the communication between the tractor and the mulch cultivator coupled to the three-point attachment, you can first alter the depth of the rear tines via the rear roller via the AutoTill. The signal for changing the length of the top link is sent to the tractor by the tilt sensor. This then adjusts the length of the hydraulic top link until it receives a signal from the tilt sensor to report that the cultivator is aligned parallel to the ground again. This means that the front tines are now working at the same depth as the rear ones.

In this way, both the correct setting of the machine can be guaranteed, and, on the other hand, varying working depths can also be actuated when planning the work in the field.

Constant operational reliability

Mulch cultivators are designed with a frame height, tine spacing, and tine stagger that permit even large volumes of organic material and soil to flow through the device.

However, blockages may occur under unfavourable conditions, such as with lodged grain, for example. In this case, it is particularly important in autonomous driving, that this blockage is detected early and is rectified using AutoTill. The driver is also supported by the system with automatic working when using a standard tractor. This means that the AutoTill can detect blockages in the machine which are difficult or impossible for the driver to detect because of the dust generated whilst working. This further increases the operational reliability of the machine.

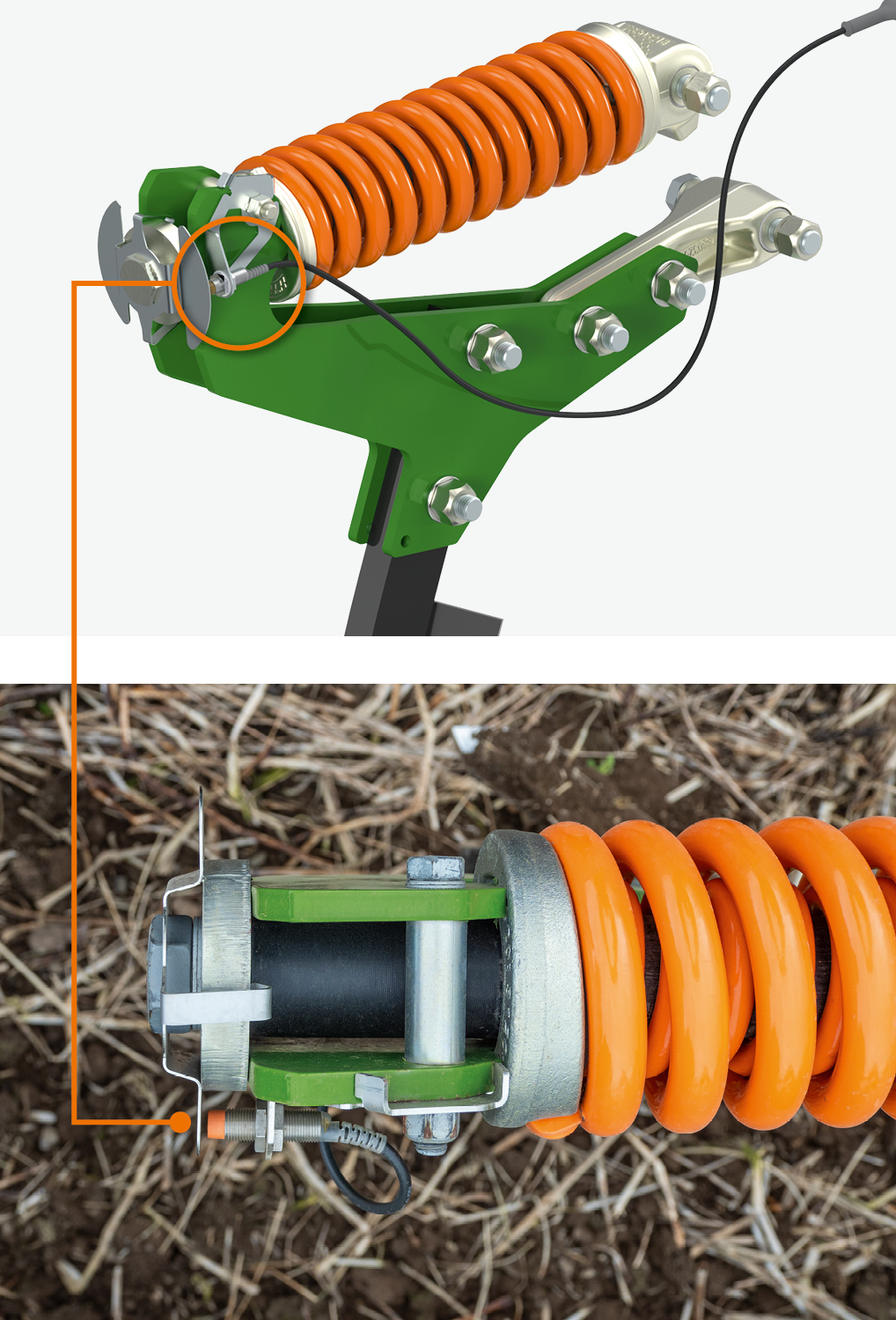

With AutoTill, AMAZONE has developed a mechanical function monitor that detects blockages caused by organic material in the machine at an early stage, thus preventing a complete blockage. Detection is by means of pressure sensors integrated in the tine element. They detect, at an early stage, whether organic material or soil is building up in the machine, they issue a warning to the driver, and instigate a solution of the problem. The benefit of the mechanical system, as opposed to a camera system, is in the operational reliability. Camera systems are at the limit of their capabilities during soil tillage on account of the amount of dust. In addition, cameras are often exposed to stones and soil during soil tillage, and this can quickly lead to damage to the cameras.

The travelling speed of the roller is also measured and compared to that of the tractor. The calculated difference between the travelling speed of the tractor and the roller allows you to detect slip on the roller. This allows you to detect a build-up of soil in front of the rear roller.

There are various different strategies incorporated into AutoTill to resolve a blockage problem.

One solution is that the system reduces the working depth and the working speed when a blockage is detected, and which can resolve the blockage within the tine element. It is possible to store additional variations for resolving problems into AutoTill to match the soils and surface organic matter and to select them as a solution strategy during the pre-planning.

In this way, we can ensure that the machine will react to problem situations independently and ensure that autonomous operation is also retained under difficult conditions. The pressure on the driver is also further reduced by automatic working.

Monitoring the overload safety device

Monitoring the overload safety device makes it possible to monitor the performance limits of the cultivator. This helps with selecting the shares and the corresponding working depth. For example, when working at a greater depth with 80 mm wide shares and 350 mm wing shares, the system can issue a recommendation to change the shares if the overload safety device triggers repeatedly.

Accordingly, at the stipulated parameters “Working Depth 30 cm” and “Working Speed 10 km/h”, AutoTill can indicate the recommendation on the terminal, in this case to change to a 40 mm narrow share. This will reduce the load on the cultivator, the wear on the shares, and the fuel consumption.

In addition, the system can detect the soil conditions, harmful compaction, and larger stones within the soil, and they can then be specifically loosened or subsequently be removed.

Monitoring the share points

The share points are monitored by an inductive sensor in order to provide high levels of operational reliability and working quality of the mulch cultivator. The use of this sensor means that you can detect the loss of a point caused by a collision with a stone, for example. This monitoring system warns the driver directly that a point is defective. This allows the driver to replace the point in good time, before the tine stem can suffer any wear. This minimises downtime and wear costs.

AutoTill for automatic and autonomous driving

AutoTill makes it possible to use a mulch cultivator automatically with a standard tractor with ISOBUS functionality in order to support the driver when using the mounted unit. This means that long days in the field are no problem for the driver.

The benefit of autonomous working lies in the independent detection and solution of problems on the ground. In combination with the 3A concept (Advanced Automation and Autonomy – the open partnership for more efficiency and empowerment) it is now possible to carry out planning of a job, working the soil in an operationally reliable and autonomous manner, and providing documentation of the job. Problem situations can be resolved autonomously whilst working thanks to the communication between the tractor and the mounted machine. This makes it possible to use autonomous tractors and mounted machinery in 24-hour shifts in a highly-efficient manner.

- Soil tillage can be carried out automatically and the load on the driver can be reduced

- The system can operate autonomously in combination with robots

- Faults in the field are detected and automatically prevented

- Expenditure on personnel is reduced

- Increased efficiency, reduced operating and machine costs

AMAZONE AutoTill