Sep 12, 2023

New AMAZONE Tyrok 400 Onland semi-mounted reversible plough

AMAZONE is now offering the Tyrok 400 semi-mounted reversible plough for on-land ploughing. The Tyrok Onland provides a high level of flexibility as a result of the quick and easy change between on-land or in-furrow operation. The new models are offered with a choice of 7, 8 or 9 furrows for tractors of up to 400 hp.

Easy change between on-land and in-furrow

The tractor size and the size of the tyres determine, amongst other things, its operation in the furrow or on and beside the furrow. In particular, its use with tracks, dual wheels or extra wide tyres larger than 710 mm does not allow for driving in the furrow without compaction damage on soil which has already been partly ploughed.

A major advantage of on-land ploughing is the reduced soil pressure as a result of the large contact area of the wide tractor tyres and the possibility of being able to work with a lower tyre pressure. This means that considerably less compaction damage is caused. Furthermore, on-land operation provides an improved pull line as a result of the reduced lateral pull and more efficient power transmission. GPS guidance systems can also be used for maximum working comfort and for a precise match-up to the next furrow. Constant depth control is provided via the front guide wheel, which runs permanently on the unworked soil.

Other factors, such as the soil conditions, have a critical impact on the method of ploughing. A quick and easy change between on-land and in-furrow operation is therefore extremely important. If the soil surface in the field does not allow for optimum traction as a result of rain or wet conditions, quick conversion to in-furrow operation is possible at any time. A twist of the hydraulic lever on the turnover arm is all that is required for this.

Pure robustness without compromise

The Tyrok Onland has a substantial, high-tensile rectangular steel beam in dimensions of 200 x 150 x 10 mm. This gives the Tyrok Onland an extremely high level of rigidity. A decisive advantage over a square beam is that the beam does not bend, even under hard soil conditions. This ensures a uniform working depth over the entire length and working width, which is crucial, especially at the larger furrow widths.

The Tyrok Onland also scores with its SmartTurn system. On the headland, the fast turning procedure is hydraulically slowed down two-fold just before the end. This results in a damping effect which reduces stress on the plough structure when the cylinder is retracted. There is no need to compromise on speed. In the Onland variant, the "beam" is automatically retracted via the Onland cylinder before the turnover process, so that the turnover centre of gravity is as low as possible and the forces acting on the tractor and plough are kept to a minimum.

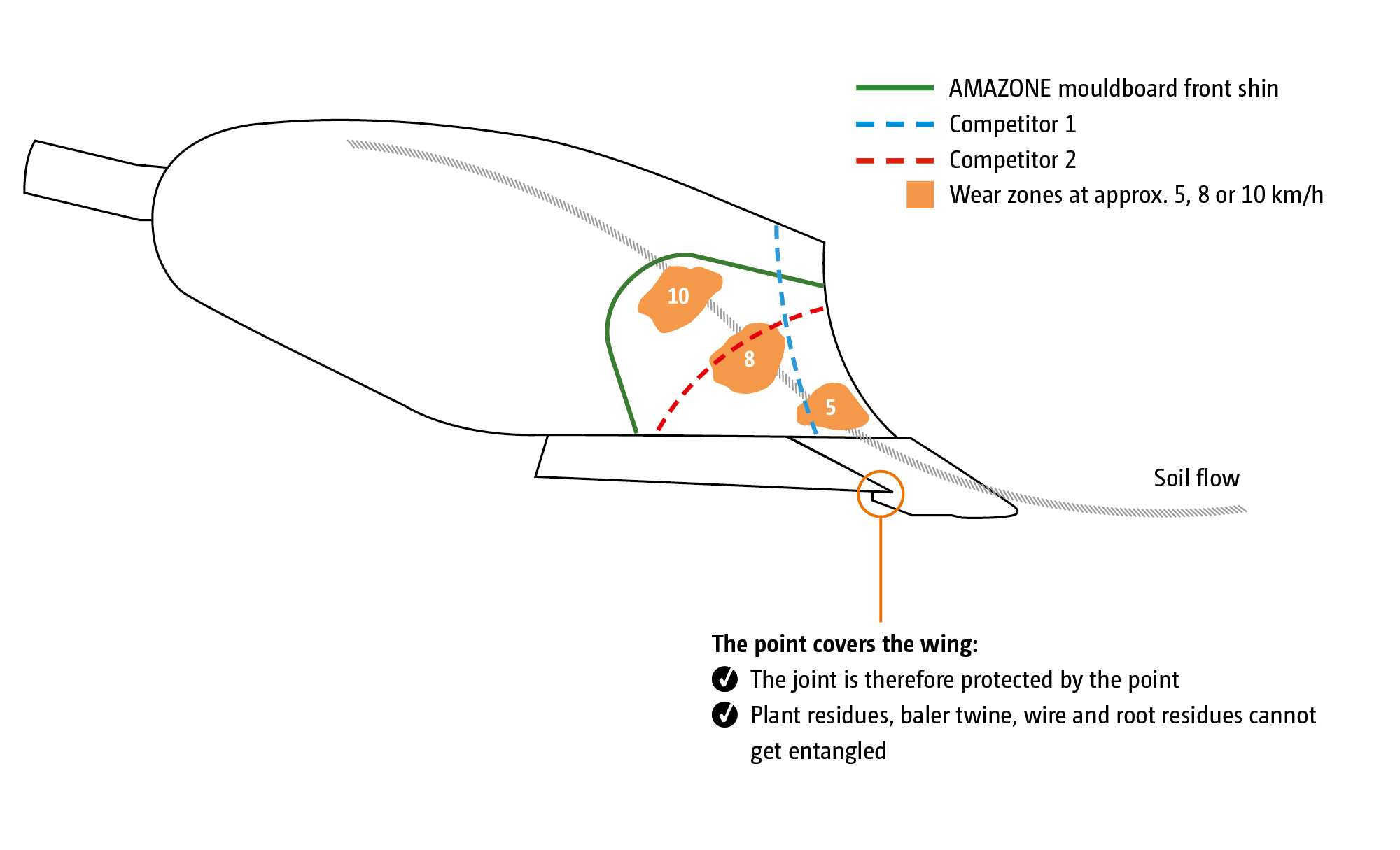

Plough bodies meticulously thought-through – SpeedBlade for less wear

The SpeedBlade plough body, with its patented extra-large front shin on the mouldboard, makes for minimal wear on the shin. The main wear point automatically shifts further and further back towards the centre of the plough body when increasing the working speed from say 6 km/h up to 8 km/h. As a result, the main wear point is kept on this enlarged front shin of the mouldboard and away from the main mouldboard, even at high forward speeds; Various slatted and solid mouldboard profiles are available depending on the application and objective.

Another detail with great effect: the point covers the blade, meaning that the joint is protected by the point. Thanks to this clever join up, no plant residues or baler twine can get entangled.

AMAZONE sets the highest standards in the manufacture of plough wearing parts with its unique ©plus hardening process. The additional introduction of carbon makes Tyrok wearing parts far harder and more durable.

Safe, comfortable and precise adjustment for a perfect working profile

The Tyrok Onland is equipped with manual furrow width adjustment as standard. As an option, the furrow width can be infinitely adjusted hydraulically to suit the conditions from the comfort of the tractor cab. The front furrow can also be adjusted manually or hydraulically for precise matching to the last furrow. An advantage here is the direct linkage of the front furrow cylinder at the front of the plough, even while driving.

Electro-hydraulic furrow depth adjustment for the Tyrok 400

The furrow depth on the Tyrok 400 can be adjusted fully hydraulically from the tractor cab thanks to the new electro-hydraulic furrow depth adjustment.

The spool valve in the tractor cab can be used to steplessly adjust the furrow depth in line with the soil conditions while driving. In this regard, lifting at the headland and changing the furrow depth on the plunger cylinder can be selected electrically. This pre-select function enables the two functions to be actuated on the Tyrok via a single-acting spool valve.

An easily visible scale on the cylinder serves as an indicator when changing the furrow depth. The electro-hydraulic furrow depth adjustment means that furrow depth adjustment is easier than ever and the comfort for the driver yet further enhanced.

- High flexibility thanks to the quick and comfortable change between on-land and in-furrow operation

- In addition to precise matching to the last furrow via GPS, on-land operation reduces the pressure on the soil as a result of the larger contact area of the tractor tyres

- Electro-hydraulic furrow depth adjustment from the tractor cab

- The AutoAdapt hydraulic front furrow adjustment is fitted as standard and provides perfect matching to the last furrow, even under varying conditions

- Unique SpeedBlade plough bodies with an enlarged front shin of the mouldboard and the ©plus hardening process allow higher speed with less wear

- Fast turning with low stress as a result of the SmartTurn two-stage hydraulic end position damping

Tyrok 400 Onland semi-mounted reversible plough