Product overview

Your benefits at a glance

- Efficient and intuitive

Quick adjustment for precise spread patterns up to 36 m and 390 kg/min - Profis weighing system

Precise application rates thanks to the 200 Hz weighing system – enter the spread rate and drive off. There is nothing simpler. - Electric Limiter V+

Always the most effective border spreading method – Comfortable change between border spreading techniques from the cab - Comfortable operation

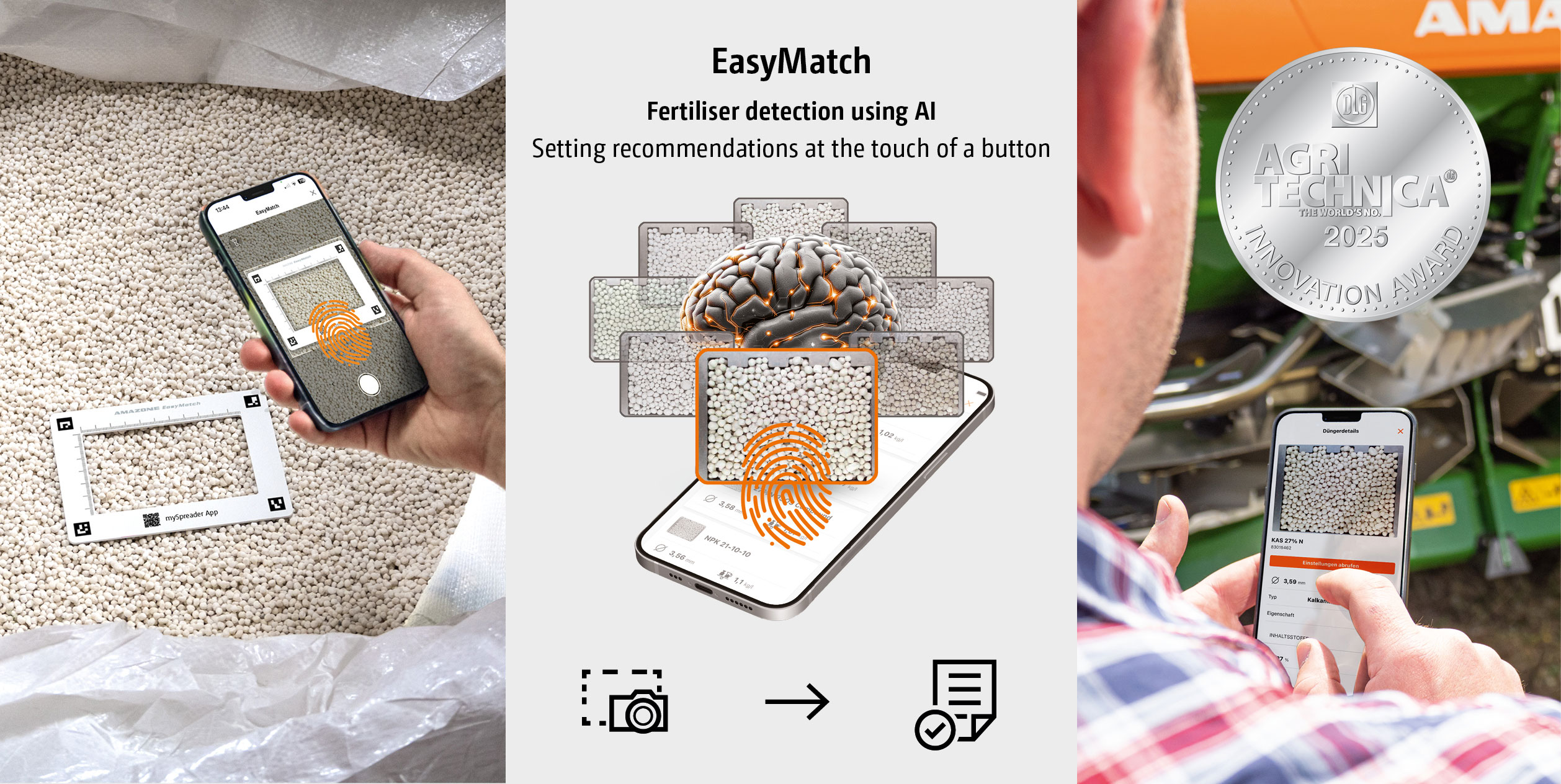

Easy set-up using the QuickSet blade adjustment and the intuitive mySpreader App – the latest fertiliser database is always at hand - Deep-drawn base hopper

No edges or weld seams – easy cleaning and no fertiliser wastage - Durability

Maximum longevity thanks to a combination of cathodic dip priming and powder coating